Titanium Nickel Clad

Updated : Oct. 23, 2025Titanium Nickel Clad Plate combines titanium’s resistance to chloride corrosion with nickel’s alkaline conductivity. This delivers reliable performance with 20–60% cost savings.

It meets ASTM B898 and comes with EN 10204 3.1/3.2 and UT test reports. Custom options include Cut-to-Size, Tube Sheets, and Heads for flexible delivery.

Why choose titanium nickel clad?

- Titanium resists seawater and oxidation, while nickel withstands strong alkali and reduction—two functions in one plate, with longer service life.

- Compared to solid Ti or solid Ni, life-cycle cost can drop by 20–60%.

- Width up to 4200 mm and length up to 12000 mm reduce welds and minimize leakage risk.

- Weldable and machinable, with Cut-to-Size and complete package supply to speed up project execution.

Titanium nickel clad specifications

- Titanium cladding B265/SB265

- Nickel side B162/SB162

- Clad plate governing standard:ASTM B898

- ASTM A516 / A24

Full certification with EN 10204 3.1/3.2 and UT Class B as standard (A–C optional), with additional NDE available on request.

Titanium nickel clad popular products

| Parameter | Standard production | Maximum capability |

|---|---|---|

| Total thickness | 8–120 mm | 5–500 mm |

| Cladding, Ti/Ni | 2–15 mm | ≤100 mm |

| Base | 5–120 mm | 0.5–300 mm |

| Width | ≤4200 mm | Custom to order |

| Length | ≤12000 mm | Custom to order |

| Build-up | 2–15 / 5–60 mm | Custom to order |

| Tolerance | ASTM B898 | Custom to order |

We offer flexible customization on thickness, width and length, with rapid production scheduling to ensure fast delivery.

Nickel clad titanium bimetal plate

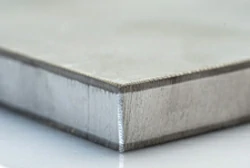

Titanium Nickel Clad Plate combines the corrosion resistance of titanium and nickel in different media, making it ideal for chemical and pressure vessel equipment.

Contact us now

Compared with solid titanium or solid nickel plates, the clad solution is more cost-effective.

When equipment faces two different corrosive environments (for example, one side needs titanium and the other nickel), Ti–Ni clad plate is the most practical choice.

- Total thickness 8–120 mm (higher thickness customizable)

- Cladding thickness 2–15 mm

- Width ≤ 4200 mm

- Length ≤ 12000 mm

It is widely used for equipment lining, heat exchangers, towers, and storage tanks where both strength and corrosion resistance are required.

Cut-to-Size service is available, with pre-machining options such as drilling, slotting, and beveling. The large plate size reduces weld seams and minimizes leakage risk.

Titanium nickel clad tube sheet

The tube sheet handles both titanium and nickel media. Holes are precision-machined to drawing and ready for assembly on delivery.

Contact us now

Machining includes hole drilling, slotting, chamfering, and sealing surface treatment to guarantee flatness and hole spacing accuracy. Supplied with UT Class B and bend/shear reports.

- Thickness 40–200 mm (customized per project)

- Diameter ≤ 4200 mm

It is mainly used in heat exchangers and condensers, ideal for dual-media conditions such as seawater and process fluids.

Titanium nickel clad pipe fittings

Titanium Nickel Clad fittings mainly include heads (dished ends) and flanges/rings, used for end closure and large-diameter connections in pressure vessels, heat exchangers, and piping systems.

Contact us now

They are custom-made to drawing, with common diameters up to 4200 mm, and can be supplied with beveling, hole patterns, and end-face machining.

Available options include elliptical, dished, and hemispherical heads. Flanges and rings support CNC cutting, end-face machining, and pre-drilled holes or spigots.

All formed parts ensure no delamination at the clad interface, meeting long-term service requirements.

Electrode / conductive backplate

The nickel side ensures stable conductivity, while the titanium side provides long-term corrosion protection—balancing efficiency and service life.

Contact us now

Widely applied in electrolyzers, electroplating tanks, and SX-EW systems, it offers dual assurance of current transmission and corrosion resistance.

- Nickel side delivers stable conductivity for efficient current transfer.

- Titanium side resists corrosion, extends equipment life, and reduces maintenance.

- Busbar connection holes can be pre-machined for easier installation.

When ordering, please specify required current density, surface roughness, hole layout, and whether coating or plating processes are needed.

Titanium nickel clad applications

Chemical / petrochemical / power

Pressure vessels, reactors, evaporators, and pickling tanks combine high-strength support with corrosion-resistant lining.

Heat exchangers / condensers

Used in offshore platforms, power plants, and saltworks. The Ti/Ni clad structure delivers excellent thermal conductivity and corrosion resistance.

Electrolysis and electroplating

Applied in chlor-alkali, electrolyzers, electrode backplates, SX-EW, and plating equipment. Nickel ensures conductivity, while titanium provides a corrosion barrier.

Seawater engineering / shipbuilding

For desalination units, ship structures, and subsea pipelines. Titanium resists pitting and crevice corrosion, while nickel adapts to alkaline process fluids.

Pulp, environmental, and energy

In bleaching sections, wet flue gas, waste recovery, and island heat exchangers. It reduces downtime and maintenance in erosion–corrosion environments.

Research and advanced equipment

Special uses such as polarizers and shape memory devices benefit from the magnetic/non-magnetic combination and shape-memory effect of Ti–Ni.

Titanium nickel clad surface treatment & machining guidelines

Surface treatment

Plates can be supplied polished or brushed (Ra 3.2–6.3 µm). Optional pickling, passivation, or sandblasting (SA2.5) improves cleanliness and corrosion resistance.

Cutting methods

Waterjet or sawing is recommended. For plasma cutting, the titanium side must be fully protected to prevent oxidation and embrittlement.

Machining

Use low speed, high feed, and ample cooling with carbide tools. Avoid cross-contamination to maintain precision and surface quality.

Welding

Select matching filler metals by material. Full shielding and transition layers are required to ensure interface stability and prevent delamination.

Titanium nickel clad performance table

- Nickel Clad Titanium Plate has been tested and shows:

- High strength: tensile strength about 479 MPa, yield strength about 330 MPa.

- Excellent toughness: bending test R=2t, inside bend >180° with no delamination.

- Reliable interface: torsion samples reach ≥360° without fracture, proving strong metallurgical bonding.

| No | 1 | 2 | 3 | 4 | 5 | Average |

|---|---|---|---|---|---|---|

| σt /MPa | 270 | 360 | 575 | 565 | 628 | 479 |

| σf /MPa | 224 | 302 | 345 | 338 | 421 | 330 |

| Bending angle (d=2t, Inner bending)/(°) | >180 | >180 | 167 | - | - | - |

Torsional performance of nickel clad titanium composite plate

| No | Sampling location | Sample dimension/mm | Twist angle/(°) |

|---|---|---|---|

| 1-1 | First half | 10×10×200 | >360 |

| 2-1 | First half | 10×10×200 | 360 |

| 1-2 | Second half | 10×10×200 | 73 |

| 2-2 | Second half | 10×10×200 | 56 |

Titanium nickel clad production methods

Titanium nickel clad plates can be produced by casting, forging, powder metallurgy, welding, and composite rolling.

For industrial use, the most proven methods are roll bonding, explosive welding, and combined explosive welding plus rolling.

- Strong interface bonding — metallurgical bond with high resistance to delamination.

- Wide size range — capable of producing large formats and thick sections.

- Stable performance — mechanical and corrosion properties meet ASTM B898 and other international standards.

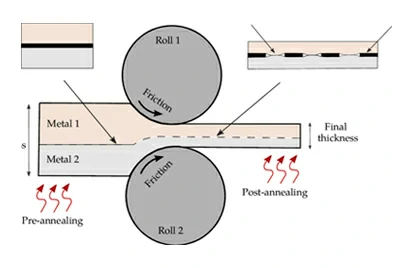

Roll Bonding

Process: Titanium and nickel plates are stacked and repeatedly rolled under high temperature and high pressure, creating a metallurgical bond.

Features: Stable interface bonding, suitable for large-area clad plate production.

Explosive Welding

Process: Explosive energy generates high-velocity impact, instantly bonding titanium and nickel with a wavy metallurgical interface.

Features: Produces strong wavy bonds, ensuring high shear and peel strength.

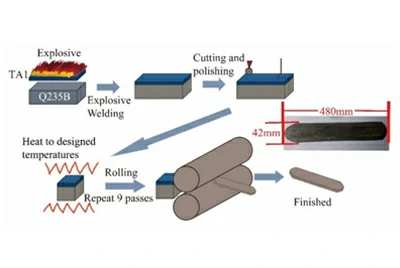

Explosive Welding + Rolling

Process: Explosive welding forms a solid bond first, followed by hot or cold rolling to improve dimensional accuracy and surface quality.

Features: Combines strong bonding with precise dimensions, ideal for high-standard engineering projects.

Quality testing & certification

- UT ultrasonic testing: executed to Class A/B/C (default Class B), full scanning from the clad side.

- Penetrant testing (PT): 100% inspection on multi-plate weld joints to eliminate leakage risk.

- Shear strength: verifies metallurgical bond integrity (≥200 MPa).

- Tensile and bending tests: ensure high strength and good formability of clad plates.

- Metallography and hardness distribution: check interface cleanliness and uniform structure.

- MTR / material certificates: EN 10204 3.1 / 3.2.

- Complete reports: include UT scan maps, shear/tensile/bending results.

- Welded components: can be supplied with WPS/PQR (welding procedure qualification) and NDE reports.

- Full barcode traceability: from melting to finished product, with permanent record keeping.

Delivery & service assurance

Common sizes are kept in stock for fast scheduling.

Packaging includes PE protective film, moisture-proof bag, desiccant, and ISPM-15 wooden cases/pallets. Corners are reinforced, and large items are secured with steel bands.

Available finishes: mill, brushed/polished, acid pickling & passivation, and SA2.5 sandblasting.

Each plate is marked with grade, dimensions, build-up (e.g., 8+42=50 mm), heat/plate number, side marking (Ti/Ni), flow direction arrow, net/gross weight, and inspection stamp.

Documents include MTR (EN 10204 3.1/3.2), dimension list, UT/shear/bend test reports, packing list, and welding recommendation card.

Flexible payment terms (T/T, L/C, etc.) are supported. DDP (Delivered Duty Paid) is available to handle customs clearance and transport for customers.

Customer support is provided in English, Spanish, French, German, Russian, and other languages to serve global clients.

Related products – clad metals solutions

Explore more clad metal solutions—besides copper-aluminum composite, we also supply titanium clad copper, copper clad steel, aluminum clad steel and other tailored combinations to match your industry needs.

Copper Clad Steel

Copper Clad Aluminum

Aluminum Clad Steel

Titanium Clad Aluminum

Titanium Clad Copper

Titanium Clad Steel

Click to view our clad product page, featuring all titanium clad materials.

FAQs

What is the difference between Ti–Ni clad and Ti-steel / Ni-steel clad?

If both sides of the equipment need corrosion resistance (e.g., seawater vs. alkaline solution), choose Ti–Ni clad. If only one side requires noble metal protection, Ti-steel or Ni-steel clad is more economical.

Can you produce large-size tube sheets or heads?

Yes. Maximum width ≤4200 mm and length ≤12000 mm, with integrated drilling and beveling to shorten installation time.

What testing and certification do you provide?

Standard UT Class B, shear/bend/tensile tests, plus EN 10204 3.1/3.2 material certificates and complete inspection reports.

What are the delivery time and minimum order quantity?

MOQ from one piece. Common sizes can be quickly scheduled, with both standard and expedited options available.

Does it have a cost advantage compared with solid titanium equipment?

Yes. Ti–Ni clad uses titanium/nickel only on the working surface, with the base providing structural strength. This typically saves 20–60% in material cost and lowers long-term maintenance expenses.