Titanium Shoulder Bolts

Our titanium shoulder bolts offer both high precision and versatility, combined with titanium alloy's exceptional lightweight properties, superior strength, and unmatched corrosion resistance.

Titanium Shoulder Bolts Product Options

- Manufactured to ASME B18.3 and ISO 7379 standards for precise fit and reliable performance.

- Available in special head styles such as hex head, slotted head, and TX (Torx) head to suit different assembly needs.

- Surface finishes include anodized coatings in blue, red, black, yellow, and heat-colored titanium gradient for enhanced corrosion resistance and visual appeal.

We offer one of the most cost-effective titanium shoulder bolt solutions on the market. Custom designs can be produced according to your drawings for unique applications. Quick Quote

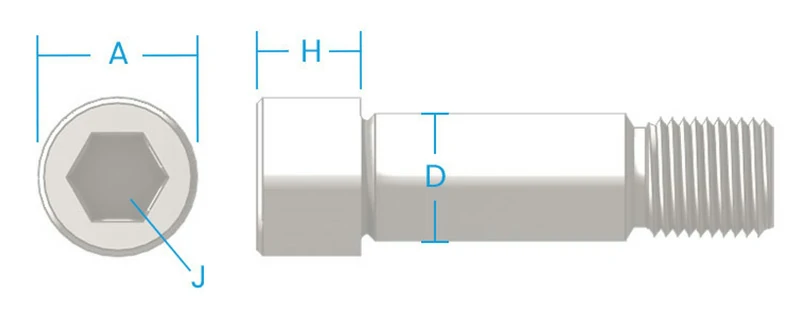

Hex Socket Head Shoulder Bolts

Titanium Shouldered Flange Hex Bolt

Titanium Pan Head Hex Socket Shoulder Bolt

Ventilated Shoulder Bolts

Shoulder Bolts With Locking Plate

Torx Drive Shoulder Bolts

Slotted Shoulder Bolts

Hex Socket Countersunk Head Shoulder Bolts

Ultra-Low Head Shoulder Bolts

Popular Sizes of Titanium Shoulder Bolts

Standard shoulder bolts feature tight tolerances, making them suitable for most machinery and equipment.

| NOMINAL SIZE | SHOULDER DIAMETER (D) | HEAD DIAMETER (A) | HEAD HEIGHT (H) | HEXAGON SOCKET SIZE (J) | |||

|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | NOM | |

| 1/4 | 0.2480 | 0.2460 | 0.375 | 0.357 | 0.188 | 0.177 | 1/8 |

| 5/16 | 0.3105 | 0.3085 | 0.438 | 0.419 | 0.219 | 0.209 | 5/32 |

| 3/8 | 0.3730 | 0.3710 | 0.562 | 0.543 | 0.250 | 0.240 | 3/16 |

| 1/2 | 0.4980 | 0.4960 | 0.750 | 0.729 | 0.312 | 0.302 | 1/4 |

| 5/8 | 0.6230 | 0.6210 | 0.875 | 0.853 | 0.375 | 0.365 | 5/16 |

| 3/4 | 0.7480 | 0.7460 | 1.000 | 0.977 | 0.500 | 0.490 | 3/8 |

| 1 | 0.9980 | 0.9960 | 1.312 | 1.287 | 0.625 | 0.610 | 1/2 |

| 1-1/4 | 1.2480 | 1.2460 | 1.750 | 1.723 | 0.750 | 0.735 | 5/8 |

| 1-1/2 | 1.4980 | 1.4960 | 2.125 | 2.095 | 1.000 | 0.980 | 7/8 |

| 1-3/4 | 1.7480 | 1.7460 | 2.375 | 2.345 | 1.125 | 1.105 | 1 |

| 2 | 1.9980 | 1.9960 | 2.750 | 2.720 | 1.250 | 1.230 | 1-1/4 |

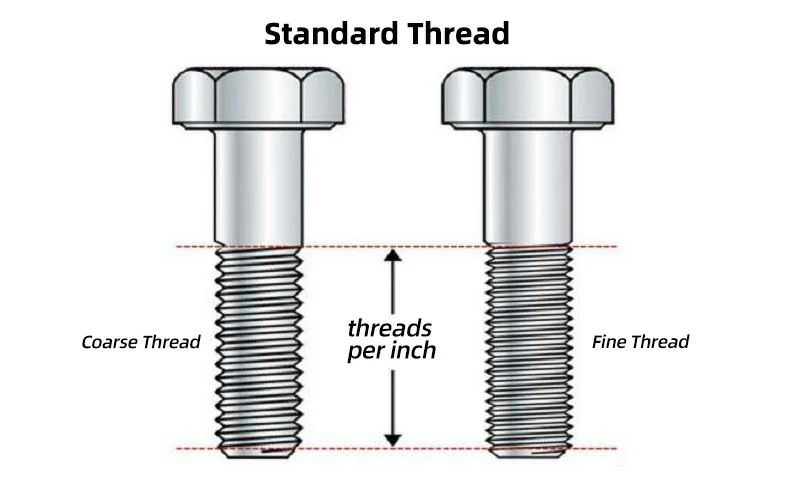

Thread Options: Guide to Choosing Coarse or Fine Threads

Different thread types can significantly impact bolt performance.

| BASIC SHOULDER DIA. | BASIC THREAD DIA. | THREADS PER IN. | |

|---|---|---|---|

| 1/4 | 0.250 | 10 | 24 |

| 5/16 | 0.312 | 1/4 | 20 |

| 3/8 | 0.375 | 5/16 | 18 |

| 1/2 | 0.500 | 3/8 | 16 |

| 5/8 | 0.625 | 1/2 | 13 |

| 3/4 | 0.750 | 5/8 | 11 |

| 1 | 1.000 | 3/4 | 10 |

| 1-1/4 | 1.250 | 7/8 | 9 |

| 1-1/2 | 1.500 | 1-1/8 | 7 |

| 1-3/4 | 1.750 | 1-1/4 | 7 |

| 2 | 2.000 | 1-1/2 | 6 |

Surface Finish Options: Combining Custom Looks with Corrosion Resistance

In the aftermarket and high-end applications, bolts need to deliver not only top performance but also style and quality. We offer a variety of finishing processes to make your titanium shoulder bolts both durable and visually striking.

- Anodizing: Multi-color finishes (blue, gold, purple, red, gradient) to enhance corrosion resistance and surface hardness.

- PVD vacuum coating: Metallic finishes such as TiN, CrN, and AlTiN with high hardness (≈2000 HV) for superior wear and scratch resistance.

- Mirror polishing: High surface smoothness (Ra ≤ 0.2 µm) for a pure metallic look that’s easy to clean.

- Matte sandblasting: Sleek matte texture for a modern, technical feel, fingerprint resistance, and improved fatigue life at the micro level.

Black Shoulder Bolts

Blue Shoulder Bolts

Burned Shoulder Bolts

Gold Shoulder Bolts

Silver Shoulder Bolts

Red Shoulder Bolts

Alloy Material Selection

| Material grade | Alloy designation | Main composition | Typical tensile strength |

|---|---|---|---|

| Grade 2 | CP-Ti | Ti ≥ 98.9% | 485 MPa |

| Grade 5 | Ti-6Al-4V | Al 5.5–6.75% / V 3.5–4.5% | 896 MPa |

| Grade 7 | Ti-0.2Pd | Pd ≈ 0.12% | 825 MPa |

| Grade 12 | Ti-0.3Mo-0.8Ni | Mo 0.3% / Ni 0.8% | ≈ 620 MPa |

| Grade 23 | Ti-6Al-4V ELI | Al 5.5–6.75% / V 3.5–4.5% | ≈ 860 MPa |

Each titanium alloy offers unique advantages. You can choose the most suitable shoulder bolt material based on your needs for strength, corrosion resistance, biocompatibility, or heat resistance. For technical selection advice or free samples, feel free to contact us anytime! Quick Quote

Applications and Typical Uses

Aerospace

Used for fastening wing skins, fuselage structures, and engine accessories. Lightweight design significantly reduces fuel consumption, while high fatigue strength ensures flight safety.

Racing and High-performance Vehicles

Installed in engine components and suspension systems, with the shoulder acting as a rotating bushing or bearing shaft. Reduces overall vehicle weight, enhancing acceleration and handling performance.

Marine Engineering

Applied in submersible interfaces, hinges for underwater robots, and rotating parts in seawater pumps and valves. Titanium alloys offer natural resistance to seawater corrosion, ensuring long-term reliability.

Molds and Automation Equipment

In stamping and injection molds, the shoulder serves as a guide post or slider guide to keep mold halves perfectly aligned. Used in joints and linear guides of automated equipment, combining high precision with wear resistance.

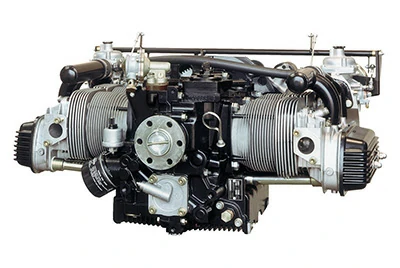

Motors and Transmission Systems

Functions as a rotor support bushing or gear bearing in high-speed applications. Titanium motor head shoulder bolts provide excellent rigidity and fatigue resistance, making them ideal for aerospace miniature motors and precision servo motors.

How to Choose the Right Shoulder Bolt

Determine the material grade

We keep regular stock of Grade 2 (biocompatible), Grade 5 (high strength), Grade 7 (enhanced corrosion resistance), Grade 12 (wear and corrosion resistance), and Grade 23 (ELI medical grade). Select the material based on strength, corrosion resistance, and biocompatibility requirements.

Choose the shoulder size

The shoulder diameter determines the support surface or sliding fit size, matching your equipment bore or guide part dimensions (e.g., Ø6 mm, Ø8 mm, Ø10 mm). Determine the length according to the required support depth or guiding stroke, typically available from 5 mm to 80 mm.

Select the thread specification

Match the thread to the shoulder diameter (e.g., Ø6 mm → M5 or M6 thread). Some standard bolts come with long threads—if you need full or short threads, please consult us.

Consider head height and drive type

Low-profile heads (lower than the shoulder height) suit space-limited applications; standard heads provide a larger bearing surface. Common drive types include hex socket, Torx (TX), and Phillips. Choose the drive type that ensures optimal torque transfer and anti-slip performance.

Select the surface finish

Anodizing: colorful decorative finish + corrosion resistance.

PVD coating: high hardness + metallic decorative effect.

Polishing/sandblasting: mirror or matte finish, selected based on aesthetics and operating environment.

One-stop Titanium Bolt Solutions

In addition to titanium shoulder bolts, we offer a wide range of high-performance titanium bolt products, all available in matching materials for seamless use and convenient one-stop sourcing.

Titanium Hex Head Bolts

Titanium Socket Cap Bolts

Titanium Flange Bolts

Titanium 12 Point Bolts

Titanium Button Head Bolts

Titanium U Bolt

All fasteners can be supplied with anodizing or PVD finishing, custom threads and head types, as well as material and inspection certificates. We provide bundled packaging and shipment to save costs and time—feel free to request a combined quote! Quick Quote

People Also Ask

Q: Are titanium bolts any good?

A: Yes. Titanium bolts deliver exceptional performance, far beyond ordinary fasteners. Known for their outstanding strength-to-weight ratio, they provide strong fastening while significantly reducing overall weight—crucial for aerospace, motorsports, and high-performance machinery.

Q: What material are shoulder bolts made of?

A: Shoulder bolts can be made from various materials to suit different applications. Common options include stainless steel, alloy steel, aluminum, and titanium alloys.

Q: How do I ensure the correct torque for titanium shoulder bolts?

A: The key to optimal performance and safety is applying the correct torque.

Q: Do titanium bolts rust?

A: Titanium alloys have excellent corrosion resistance in seawater, acidic, and alkaline environments. They will not rust under normal use conditions.

Q: What surface colors are available?

A: Anodizing can create finishes in blue, gold, purple, and rainbow. PVD coatings can achieve metallic finishes such as gold, black, and silver.

Q: Do you produce ventilated shoulder bolts?

A: Yes. Ventilated bolts are suitable for high or ultra-high vacuum environments and work best with vented washers to release trapped gas under the bolt head. They are ideal for vacuum chamber applications where panels must be precisely aligned for a proper seal and high vacuum conditions must be reached quickly.

Ready to choose high-quality titanium shoulder bolts for your project? Contact us now for custom solutions and a detailed quote. Our expert team is here to deliver outstanding products and technical support. Quick Quote