Corrosion Resistant Titanium Hex Bolts

Titanium hex bolts resist corrosion and rust, performing reliably from -195 °C to 260 °C. They are non-magnetic, non-toxic, and supplied with a 3.1 material certificate and AS9100D certification.

Why We Recommend Titanium Hex Bolts

- Up to 45% weight reduction compared to steel of the same size, ideal for weight-sensitive industries like racing, cycling, and aerospace.

- Grade 5 titanium alloy tensile strength reaches 130–145 ksi, comparable to 10.9–12.9 grade steel.

- Withstands over 10 years in seawater and acidic/alkaline environments without corrosion or extra surface treatment.

- Performs in extreme temperatures from -250 °C to 400 °C.

- Anodized color finish for lasting beauty, perfect for custom motorcycles, bicycles, and other upgrades.

Titanium Hex Bolts Specifications

- ASTM F468 (on request)

- MIL-S-1222 (if required)

- ASME B18.2.1

- DIN 931 / ISO 4014

- DIN 933 / ISO 4017

- DIN 960

- DIN 961

- Standard (ASME/ANSI)

- Metric (IFI)

AS9100D and IFI-140 certificate scans available with full traceability documentation. Can also meet NACE MR0175, ASTM F468, and other oil & gas or medical standards upon request.

Popular Titanium Hex Bolt Products

We specialize in lightweight, high-strength, corrosion-resistant titanium fasteners, including hex head, socket cap, and flange types. Available in both metric and inch sizes, with ample stock for fast delivery.

Titanium Hex Head Bolts

Features: Reduce weight by 45% while maintaining Grade 5 tensile strength of 130 ksi. Direct steel replacement with lifetime maintenance-free performance.

Contact us now

Titanium Socket Cap Bolts

Features: Compact hex socket design saves space and delivers ≥ 130 ksi preload, making assemblies lighter, more stable, and easier to service.

Contact us nowTapered Socket Cap Bolts

Features: Low-profile tapered head engineered for racing and custom builds. Flush fit reduces drag, with a full set upgrade cutting up to 1 kg in vehicle weight.

Contact us now

Titanium Hex Flange Bolts

Features: Flange washer integrated design spreads load, resists vibration, and prevents loosening—zero maintenance for over 10 years in marine and high-vibration environments.

Contact us nowWe offer complete metric and inch size ranges, with quick filters and technical downloads to help you select and order with precision. 联系我们按钮

Titanium Hex Bolts Metric Specifications

| Diameter × Pitch | Available length (mm) | Approx. weight (g / 30 mm) | Recommended torque (Nm) |

|---|---|---|---|

| M3 × 0.5 | 6 – 25 | ≈ 1 | 1.4 |

| M4 × 0.7 | 8 – 40 | ≈ 2 | 4.0 |

| M5 × 0.8 | 8 – 50 | ≈ 3 | 8.4 |

| M6 × 1.0 | 10 – 60 | ≈ 4 | 16.8 |

| M8 × 1.25 | 12 – 80 | ≈ 8 | 41 |

| M10 × 1.5 | 16 – 100 | ≈ 14 | 81 |

| M12 × 1.75 | 20 – 120 | ≈ 22 | 140 |

| M14 × 2.0 | 25 – 140 | ≈ 32 | 225 |

| M16 × 2.0 | 30 – 160 | ≈ 42 | 275 |

| M16 × 2.0 | 30 – 160 | ≈ 42 | 275 |

| M18 × 2.5 | 35 – 180 | ≈ 54 | 360 |

| M20 × 2.5 | 40 – 200 | ≈ 68 | 515 |

Titanium Hex Bolts Inch Specifications

| Diameter – Thread | Available length (in) | Approx. weight (g / 1″) | Recommended torque (Nm) |

|---|---|---|---|

| #8-32 UNC | ¼ – 1½ | ≈ 3 | 3.4 |

| #10-24 UNC | ½ – 2 | ≈ 4 | 6.8 |

| 3⁄16-24 UNF | ½ – 2 | ≈ 5 | 8.0 |

| ¼-20 UNC | ½ – 3 | ≈ 6 | 11 |

| ¼-28 UNF | ½ – 3 | ≈ 6 | 13 |

| 5⁄16-18 UNC | ½ – 3 | ≈ 9 | 19 |

| 5⁄16-24 UNF | ½ – 3 | ≈ 9 | 24 |

| 3⁄8-16 UNC | ¾ – 4 | ≈ 15 | 34 |

| 3⁄8-24 UNF | ¾ – 4 | ≈ 15 | 40 |

| 7⁄16-14 UNC | 1 – 4 | ≈ 24 | 55 |

| 7⁄16-20 UNF | 1 – 4 | ≈ 24 | 68 |

| ½-13 UNC | 1 – 5 | ≈ 32 | 81 |

| ½-20 UNF | 1 – 5 | ≈ 32 | 100 |

| 5⁄8-18 UNF | 1 – 6 | ≈ 55 | 160 |

| 3⁄4-16 UNF | 1½ – 6 | ≈ 92 | 270 |

If you can’t find the size you need—such as fine thread, extended thread length, or non-standard head type—click here to contact us for a custom order. 联系我们按钮

How to Choose Titanium Hex Bolt Grades

| Alloy grade | Material name | Key features | Typical applications |

|---|---|---|---|

| Grade 2 | CP-Ti (commercially pure titanium) | Excellent ductility, resistant to seawater and acid/alkali corrosion | Marine engineering, chemical equipment, heat exchanger supports |

| Grade 5 | 6Al-4V | High strength, good machinability, widely used | Aerospace parts, racing, bicycles, mechanical fasteners |

| Grade 23 | 6Al-4V ELI | Extra-low interstitial, high toughness, suited for cryogenic and biomedical environments | Medical implants, cryogenic devices, precision structures |

| Grade 7 | Ti-Pd | Palladium added for superior chloride corrosion resistance | Chlor-alkali, electrolysis, petrochemical equipment, chlorine-rich environments |

| Grade 12 | Ti-Code 12 | Molybdenum and nickel enhanced for high strength and corrosion resistance | Pressure vessels, heat exchangers, pulp and paper, seawater cooling systems |

Titanium Hex Bolts Surface Treatment Options

Titanium hex bolts surface treatment options

We offer multiple surface finishes for titanium bolts, combining corrosion resistance, wear protection, visual appeal, and anti-galling performance.

Anodizing

Color titanium finish for both beauty and corrosion resistance—ideal for lightweight custom motorcycles, bicycles, and racing builds.

Black titanium coating

Ultra-hard coating with low friction and high wear resistance, perfect for high-speed operation or frequent assembly/disassembly.

TiN gold / PTFE gray coating

TiN offers heat and wear resistance, while PTFE prevents galling and rust—suitable for marine, high-temperature, and high-torque environments.

Customization options

Laser-etched logos, drilled safety-wire holes, non-standard lengths, small-batch runs, and complete kit packaging available.

Bare

Bronze

Burnt

Freaktanium

Light Purple

Pink

Rainbow

Sky Blue

Customization

If you need special colors, surface properties, or functional coatings, contact us—we will tailor the perfect titanium fastener solution for your needs.Quick Quote

Titanium Hex Bolts Torque–Clamp Force Reference Table

| Specification | Grade 2 recommended torque (Nm) | Grade 2 clamp force (kN) | Grade 5 recommended torque (Nm) | Grade 5 clamp force (kN) |

|---|---|---|---|---|

| M6 × 1.0 | 14 | 0.47 | 17 | 0.57 |

| M8 × 1.25 | 34 | 0.85 | 41 | 1.03 |

| M10 × 1.5 | 68 | 1.36 | 81 | 1.62 |

| ¼-20 UNC | 11 | 0.45 | 14 | 0.57 |

| 3⁄8-16 UNC | 34 | 1.36 | 40 | 1.60 |

- Grade 5 provides approximately 20–25% more clamp force at the same size, ideal for high-load and high-vibration applications.

- Grade 2 maintains excellent corrosion resistance, suitable for low-stress connections in chemical and seawater equipment.

For more precise torque–clamp force calculations, we recommend using the Engineers Edge online Torque Calculator tool.

Titanium Hex Bolts Industry Applications

Automotive / Racing / Motorcycle Customization

Automotive titanium bolts, titanium racing bolts, and motorcycle titanium bolts can cut vehicle weight by ≥ 0.9 kg. Grade 5 bolts for F1 suspension maintain clamping force at 300 km/h in high-vibration conditions. Anodized color titanium offers both scratch resistance and striking visual appeal.

Mountain Bikes & Lightweight Sports Equipment

Replacing stainless steel with M5/M6 anodized titanium bolts reduces bike weight by 58 g. After two muddy riding seasons, there is zero corrosion and the finish remains bright.

Marine Engineering & Offshore Wind Power

Grade 2 hex flange bolts show zero corrosion spots after 1,000-hour salt spray testing on marine deck specimens. Offshore wind tower connections use Grade 7, meeting NACE MR0175 standards, delivering maintenance-free performance even in long-term high-chloride environments.

Chemical & Oil/Gas Equipment

Grade 2 and Grade 12 bolts paired with non-magnetic instrument housings resist acids and hydrogen sulfide. Projects include EN 10204 3.1 + traceable heat number for process safety audits.

Aerospace Structures

Replacing A286 stainless steel in wing spar connections with Grade 5 titanium cuts structural weight by 43% while meeting AS9100D / IFI-140 compliance requirements.

High-end MRO (Power Plants, Pharmaceutical Equipment)

48-hour rapid delivery to match original thread and size specifications. PTFE gray-coated titanium bolts solve galling issues in high-temperature crystallizers, cutting on-site maintenance cycles by 30%.

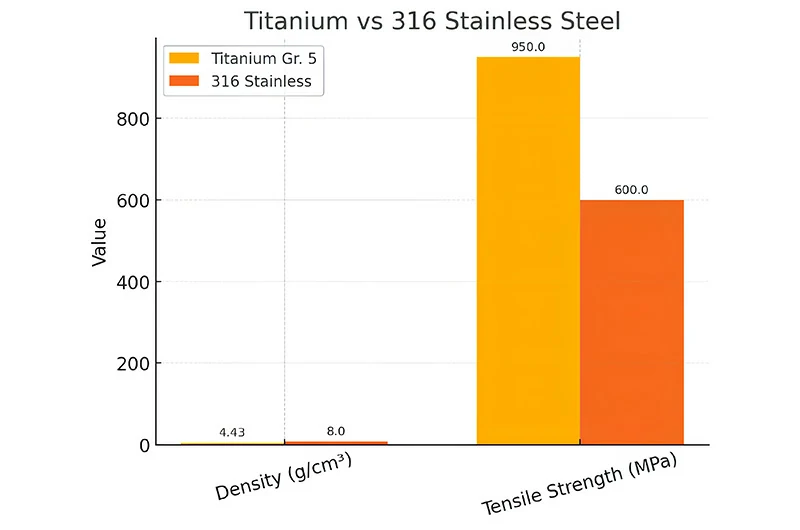

Titanium Bolts vs Stainless Steel Bolts — Weight & Strength Comparison

| Comparison | Titanium | 316 stainless steel |

|---|---|---|

| Density | 4.43 g/cm³ | 8.00 g/cm³ |

| Tensile strength | 900~1,000 MPa | 580~650 MPa |

| Salt spray test | 720 h with no rust | Prone to pitting and darkening |

| Maintenance cost | Near zero | Frequent replacement and cleaning |

| Total cost (5 years) | Lower | Higher |

Based on certified test data, titanium bolts can reduce weight by around 45% at the same strength. Each order includes a torque chart and 3.1 certificate, giving you confidence in replacement decisions and cutting maintenance costs significantly. Quick Quote

One-stop Titanium Fastener Solutions

In addition to standard titanium hex bolts, we supply a complete range of titanium alloy fasteners, including nuts, screws, washers, and studs. Multiple alloy grades (Gr.2 / Gr.5 / Gr.7 / Gr.23) and custom surface treatments are available.

Titanium Flange Bolts

Titanium Shoulder Bolts

Titanium Socket Head Screws

Titanium Hex Nuts

Titanium Flat Washer

Titanium Full Thread Studs

If you need complete sets—such as "bolt + nut + washer” in one purchase—or require special strength, anti-loosening, corrosion resistance, or non-magnetic properties, contact us today. We can tailor a full solution to your exact needs. Quick Quote

Titanium Hex Bolts Frequently Asked Questions (FAQ)

Titanium hex bolts frequently asked questions (FAQ)

Q1: What are the disadvantages of titanium bolts?

Titanium is relatively expensive and has lower shear toughness than grade 12.9 high-strength steel, so it is not recommended for high-shear or impact-load connections.

Q2: Are titanium bolts good to use?

Yes. They are lightweight, corrosion-resistant, and require no coating, making them suitable for most structural connections. Just install with the correct torque and use anti-seize compound.

Q3: Should I apply anti-seize during installation?

Yes. Titanium-to-titanium assemblies can cold weld. Use MoS₂ grease or a titanium-specific anti-seize to ensure smooth removal and prevent galling.

Q4: Are titanium bolts stronger than steel bolts?

Grade 5 titanium has higher tensile strength than grade 8.8 carbon steel and is slightly lower than grade 12.9, but it weighs nearly 50% less—offering the best balance between strength and weight.

Q5: Can titanium bolts replace stainless steel?

Yes. In high-corrosion environments such as salt spray or seawater, titanium outperforms stainless steel in durability, offering a longer lifespan and lower maintenance costs.

Q6: Do I need material reports or certifications?

All titanium bolts can be supplied with EN 10204 3.1 material certificates, and we support AS9100D / NACE MR0175 compliance for project requirements.

Q7: Can you make non-standard sizes?

Yes. We can machine to drawing, cut non-standard lengths, provide small-batch samples, and supply complete kits—contact us for customization.

Have more questions? Click the bottom-right button on this page to chat with our engineers online. We respond within 1 hour with the best selection and technical advice for your needs.