6al-4v Eli Titanium Square Bar

6Al-4V ELI titanium square bar (Grade 23 titanium square bar) is a high-strength, low-impurity, medical-grade titanium alloy square solid bar. Refined using the VIM+VAR (vacuum induction melting + vacuum consumable remelting) or EB+VAR process, the oxygen content is controlled to ≤0.13% and the hydrogen content is ≤0.0125%, significantly improving the material's toughness and fatigue life.

Chalco Titanium stocks a variety of sizes, from 10×10mm to 60×60mm, and can provide custom cut-to-size solutions. We also accept small orders. If you require a specific size or delivery time, please feel free to contact us to confirm availability and customize your solution. Click here to view our inventory details.

Why choose 6Al-4V ELI titanium square bar?

- Compared to ordinary Grade 5, 6Al-4V ELI has lower oxygen (≤0.13%) and hydrogen (≤0.0125%) contents, giving the material higher fracture toughness and more stable fatigue strength.

- ELI (Extra Low Interstitial) grade ensures less material inclusions, low internal stress, and better fracture ductility

- The square rod structure is symmetrical on all four sides, with small processing deformation and good heat treatment stability. It is suitable for precision CNC machining and subsequent anodizing, welding and other processes.

- The chemical composition does not contain toxic elements, the structure is stable, and it has excellent biological inertness and corrosion resistance to body fluids, salt spray, acid and alkali environments, making it particularly suitable for long-term service applications.

6Al-4V ELI titanium square bar specification standard

- ASTM F136

- ASTM B348

- AMS 6932

- AMS 4930

- AS9100D, ISO 13485, ISO 9001

Chemical composition standard (ASTM F136 / Grade 23)

The chemical composition of 6Al-4V ELI titanium square rods strictly complies with ASTM F136 and UNS R56401 standards, ensuring excellent purity, biocompatibility, and mechanical stability. The table below lists the controlled ranges or maximum allowable values for each key element, which are the foundation for the reliable performance of this medical implant-grade titanium alloy (Grade 23).

| Element | Content range or maximum value (%) |

|---|---|

| Nitrogen (N) | ≤ 0.05 |

| Carbon (C) | ≤ 0.08 |

| Hydrogen (H) | ≤ 0.012 * |

| Iron (Fe) | ≤ 0.25 |

| Oxygen (O) | ≤ 0.13 |

| Aluminum (Al) | 5.50 – 6.50 |

| Vanadium (V) | 3.50 – 4.50 |

| Titanium (Ti) | Balance |

Mechanical properties

| Heat treatment status | Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Sectional shrinkage (%) |

|---|---|---|---|---|

| Mill Annealed | 830–870 | 900–950 | 12–15 | 30–35 |

| Beta Annealed | ~850 | ~920 | ~10 | ~28 |

| Recrystallized annealing | ~860 | ~940 | ~11 | ~29 |

Grade 23 titanium square bars are always in stock

Chalco Titanium offers a full range of Grade 23 Titanium Square Bar (6Al-4V ELI titanium square bar), widely used in high-performance applications such as medical implants, aerospace components, and precision machining. Our stock covers cross-sectional sizes ranging from 1/8 inch (3.18 mm) to 4 inches (101.6 mm), and lengths can be cut to length upon request. We support small order quantities and fast delivery.

In addition to our regular stock, we can also provide customized services for larger sizes or special specifications according to customer needs. Please feel free to inquire for technical solutions and quotes.

| Product | Cross-sectional dimensions (in) | Cross-sectional dimensions (mm) | Length range |

|---|---|---|---|

| 6Al-4V ELI titanium square bar | 1/8" × 1/8" | 3.18 × 3.18 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 3/16" × 3/16" | 4.76 × 4.76 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 1/4" × 1/4" | 6.35 × 6.35 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 3/8" × 3/8" | 9.53 × 9.53 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 1/2" × 1/2" | 12.7 × 12.7 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 5/8" × 5/8" | 15.88 × 15.88 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 3/4" × 3/4" | 19.05 × 19.05 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 1" × 1" | 25.4 × 25.4 mm | 12–48 in / Custom |

| 6Al-4V ELI titanium square bar | 1.5" × 1.5" | 38.1 × 38.1 mm | 12–40 in / Custom |

| 6Al-4V ELI titanium square bar | 2" × 2" | 50.8 × 50.8 mm | 12–40 in / Custom |

| 6Al-4V ELI titanium square bar | 3" × 3" | 76.2 × 76.2 mm | Customized production |

| 6Al-4V ELI titanium square bar | 4" × 4" | 101.6 × 101.6 mm | Customized production |

In addition to our current stock of 6Al-4V ELI titanium square bars, we also maintain a wide selection of titanium square bars. Explore our [titanium square bars] to find the right size and shape for your project, and contact us to discuss your specific requirements.

6al-4v eli titanium square bar tolerance

Edge length tolerance

In the hot-rolled or extruded state, the side length tolerance of titanium square bars is usually controlled at ±0.3 to ±0.8 mm; if precision machining is performed, it can be further reduced to ±0.05 mm to meet the needs of high-precision applications.

Straightness control

6Al-4V ELI titanium square bar has excellent straightness, with a standard control value of ≤ 1 mm/m, and is suitable for use in high-precision assembly or long-sized structural parts.

Diagonal error

For conventional small-sized products, the diagonal difference is controlled within 0.5 mm or less. Large-sized square bars can be customized according to drawing requirements or ASTM B348 standards.

Cutting tolerance

The standard sawing tolerance range is ±1–3 mm. For higher requirements, we can provide additional processing services such as fine sawing and end milling to further improve end surface flatness and dimensional consistency.

surface roughness

The surface roughness in the pickled state can reach Ra ≤ 3.2 μm. After grinding or lathing, the roughness can be optimized to Ra 0.8–1.6 μm, suitable for applications requiring anodized or high-cleanliness surfaces.

Processing suggestions

If subsequent CNC machining, anodizing, or other processes are required, it is recommended to leave a machining allowance of 1–3 mm on each side to ensure that the final product meets the required tolerances and surface quality.

Production process types and selection recommendations

Forged titanium square bar

Cross-sections range from 25×25 mm to 100×100 mm (approximately 1" to 4"), and lengths are typically 300–1500 mm

Contact us now

Its advantage lies in its dense structure, which makes it suitable for producing large-sized, high-load structural blocks, such as aviation load-bearing parts.

While this method offers excellent performance, it also comes with relatively long lead times and high processing costs. It is widely used in high-strength areas such as aerospace structural blocks and supports. This type of square bar offers a dense structure and consistent performance, making it suitable for subsequent finishing.

Extruded / rolled titanium square bars

Cross-sections range from 10×10 mm to 60×60 mm (approximately 3/8" to 2.5"), and lengths are typically 1000–3000 mm.

Contact us now

The process flow is: ingot → extrusion/rolling → cutting to length.

Its advantages lie in high production efficiency and uniform material structure, making it suitable for mass production of standard square bar products. This method offers high yields at a moderate cost, making it suitable for applications such as medical device components and precision connectors, where consistency and strength are crucial. However, it's important to note that extrusion dies have a certain upper limit on cross-sectional dimensions, typically requiring a minimum order quantity ( MOQ).

Round bar grinding titanium square bar

Cross-sections range from 6×6 mm to 50×50 mm (approximately 1/4" to 2"), and lengths are typically 500–3000 mm.

Contact us now

The process is as follows: use the stock round bar → grind or mill the four sides into a square.

This flexible and fast method is particularly suitable for prototyping, custom small-batch orders, or projects with tight deadlines. Because the raw material is round bar, the corners have a slight R value, so slight variations in diagonal dimensions may occur. This method offers a low overall cost and is suitable for anodized test pieces, CNC proofing blocks, and R&D parts.

Near net shape titanium square bar ( AM/PM)

The cross-section range is usually 8×8 mm to 80×80 mm (about 5/16"~3.15"), and the length can be customized according to the design, generally ≤ 500 mm.

Contact us now

The process flow is: 3D printing (additive manufacturing) or powder metallurgy + HIP hot isostatic pressing → finishing.

This process supports the design of highly complex geometries and is particularly suitable for special-shaped blocks, internal cavity components, and non-standard components. It offers a high degree of design freedom, but also comes at the cost of higher overall costs and a relatively long validation cycle. It is suitable for high-value-added applications such as personalized medical implants, functional aviation components, and research and development projects.

Quality control

Multiple smelting guarantees

Grade 23 titanium square bars are produced using the VIM + VAR ( vacuum induction melting + vacuum consumable remelting ) or EB + VAR (electron beam + vacuum remelting) processes, typically with a double or tertiary melt. Compared to conventional melting routes, this method significantly reduces non-metallic inclusions and gaseous impurities, ensuring a stable and uniform microstructure, high purity, and excellent toughness, meeting the stringent requirements of medical and aerospace grades.

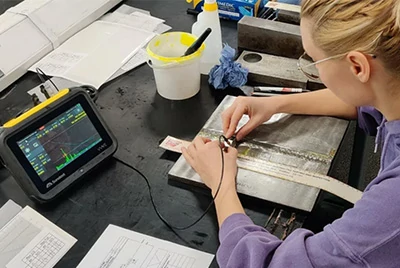

Full non-destructive testing

All products undergo 100% ultrasonic testing (compliant with UT Level A or B standards) before leaving the factory, and liquid penetrant testing (PT) is also available to effectively detect defects such as cracks, pores, and delamination. This high-standard inspection is particularly suitable for applications with extremely high structural integrity requirements, such as surgical implants and aerospace connectors.

Comprehensive verification of physical and chemical properties

In the physical and chemical testing phase, we provide separate tests for oxygen, hydrogen, and nitrogen (O/H/N) content. We also conduct full inspections or batch inspections in combination with microstructure analysis, hardness testing, tensile and yield strength testing, and elongation testing to ensure the reliable performance and traceability of each batch of products.

Authoritative certification documents support global project docking

We can provide customers with EN 10204 3.1 or 3.2 material certificates, and all materials comply with international standards such as ASTM F136 and AMS 6932. For medical applications, we can assist customers in preparing technical documentation related to MDR or FDA registration, supporting CE marking, third-party verification, and terminal compliance audits.

Frequently asked questions (FAQ)

How should I choose between 6Al-4V ELI titanium round bars and square bars?

6Al-4V ELI titanium round bars are ideal for applications requiring rotational symmetry, machining into rods, or where bending and torsional strength are critical. 6Al-4V ELI titanium square bars, on the other hand, provide flat surfaces for easier fixturing, welding, or assembly, and offer higher resistance to twisting in certain structural components. Consider both the mechanical requirements and your machining or assembly process when choosing the appropriate shape. For custom sizes, shapes, or other titanium alloys, contact us to discuss the best solution for your project.

Grade 23 and Grade 5 titanium square bars ?

Grade 23 is an ultra-clean version of Grade 5 titanium square bar. Its lower impurity content provides enhanced toughness and biosafety, making it particularly suitable for medical implants and critical applications with high fatigue and high strength requirements. Grade 23 should be preferred if you have high expectations for material cleanliness, fracture toughness, or regulatory compliance.

Can you provide 100% UT report, third-party testing?

UT maps, chemical/mechanical test reports are generally provided, and SGS/BV third-party reports are optional.

Can you make custom sizes in small batches? What is the minimum order quantity?

We can cut from 1 piece in stock; custom sections are typically ≥ 50–100 kg. Samples are welcome for confirmation.

How are tolerances controlled? How much allowance should be left for final machining?

The raw material is ±0.3~0.8 mm, the round rod is squared ±0.1 mm, and it is recommended to leave a margin of 1-3 mm/side before finishing.

Can it be anodized or polished?

We can provide polishing/anodizing services or semi-finished products to ensure medical color consistency.

How to get a quote faster?

Send us the specifications (side length × length), quantity, standard/testing requirements, and purpose to receive a quote and material certificate sample within 12 hours. Send Email.