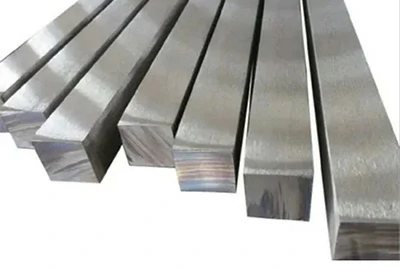

Titanium Square Bar

Titanium square bar, a solid titanium material designed for high-strength, corrosion-resistant, and precision machining, is widely used in critical structural components such as aviation fixtures, medical stents, and marine equipment. Compared to titanium plates or round bars, square cross-sections are more suitable for parts with high load and positioning requirements, such as connectors, stoppers, and mounting bases, and offer excellent dimensional stability and fatigue performance.

Chalco Titanium is available in side widths 6–150 mm. Our 100 mm titanium square bars are available in cut-to-length and CNC-machined alloys, including Gr2, Gr5, and Gr23 ELI, and comply with standards such as ASTM B348, AMS 4928, and ISO 13485. We utilize a comprehensive process of forging, finishing, and non-destructive testing to ensure each bar's high strength, precise dimensions, and consistent quality, enabling customers to reliably deliver high-performance structural components.

Why choose titanium square bar?

In scenarios such as aviation structures, medical assemblies, and marine equipment that require extremely high structural strength and corrosion resistance, titanium square bars have become an ideal material for key components due to their excellent comprehensive performance. Compared with titanium round bars or titanium plates, square bars have higher material utilization and structural adaptability, and are particularly suitable for situations requiring high-strength connections, symmetrical installation, clamping and positioning.

- The structural design is flexible, and the shape of four equal sides facilitates processing and positioning. It can be directly used to make connecting blocks, support seats, limiters and other structural parts, reducing material waste.

- The material has excellent performance. For example, Ti-6Al-4V has a tensile strength of ≥895 MPa and a density of only 4.43 g/cm³, which has an extremely high strength-to-weight ratio and is suitable for weight reduction design.

- The forged or extruded titanium square bar has good dimensional stability, dense internal structure and high fatigue life, making it suitable for critical structures under repeated loads or vibration environments.

- It has strong corrosion resistance, and the natural passivation film can resist the erosion of seawater, acid rain, and chemical media. It is widely used in harsh environmental scenarios such as marine equipment and chemical machinery.

- It has strong processing adaptability and is convenient for multi-axis finishing such as CNC milling, drilling, and tapping. It is suitable for the rapid production of small and medium-sized batch structural parts.

- Multiple alloys are available, including Gr2 (high ductility), Gr5 (high strength), Gr23 (biocompatibility), Ti5553 (high toughness) and other titanium alloys to meet the needs of different working conditions.

- High cost efficiency. Compared with plate cutting or round bar milling, square bars can reduce the amount of removal, improve raw material utilization, and reduce the overall processing cost.

Specifications for titanium square bars

Our titanium square bar products comply with the following international standards and specifications, suitable for aviation, medical, marine and high-end industrial applications, and support compliant delivery in the global market:

- ASTM B348

- AMS 4928

- AMS 4931

- ISO 5832-3

- EN 10204 3.1 / 3.2

- ISO 9001

- ISO 13485

- AS9100

- Nadcap

Our titanium square bars are all produced under the dual ISO 9001 and AS9100 certification systems, meeting the EN 10204 3.1/3.2 material traceability requirements. NACE MR0175/ISO 15156 certification for use in corrosive environments is available upon request, fully supporting high-reliability engineering applications.

The types of titanium square bars available from Chalco

Rolled titanium square bars

The titanium billet is rolled into a square cross-section in multiple passes by hot rolling or continuous rolling, and then pickled, straightened and cut to obtain the finished product.

Contact us now

- The deformation is uniform, the grain size is medium, and the internal porosity is low.

- While ensuring tensile strength, it has good ductility, which is conducive to subsequent bending and welding.

- Edge width is usually 6–100 mm, length up to 6 m.

- The whole batch continuous rolling output is high, and the raw material utilization rate is ≈ 90 %, and the cost per ton is relatively the lowest.

Typical applications: general mechanical clamping blocks, chemical supports, and welding structural parts.

Forged titanium square bar

Free forging or die forging uses multi-directional large deformation to forge the titanium ingot into a square bar, which is then rough turned, finely ground and heat treated to obtain the target size and structure.

Contact us now

- The grains are small, the texture is obvious, the density is higher, and it is often accompanied by the refinement of β→α phase.

- The fatigue limit and fracture toughness are greatly improved, and the impact resistance and crack propagation resistance are strong.

- Edge width 20–200 mm, length is generally ≤ 2.5 m (depending on the device capabilities).

- It is often combined with full ultrasonic (UT) inspection to meet AMS specifications or ISO 5832-3 requirements.

Typical applications: aviation fixture supports, marine limit blocks, and medical external fixation components.

Extruded titanium square rod

The hot extrusion process pushes the titanium billet out of the extrusion barrel under high temperature and high pressure, and forms it through a square die; the subsequent stretching, straightening and cutting steps ensure straightness and dimensional consistency.

Contact us now

- The fibrous streamlines are distributed along the axial direction, resulting in higher dimensional accuracy.

- The straightness is better than that of rolled products, and the tolerance can be easily controlled to ISO h9; it is suitable for long lengths and high consistency requirements.

- Edge width 10–120 mm, standard length 3–4 m, longer lengths can be customized.

- Cross-section specifications can be quickly switched by changing the mold, which is suitable for medium-volume orders with diversified specifications.

Typical applications: precision guide rails, positioning supports, robot frames and high-end mechanical fixtures.

Selection recommendations:

- Pursuing high strength and long life – choose forged titanium square bars, which can be combined with vacuum annealing and ultrasonic testing to ensure the safety factor of key parts.

- Large quantities, cost-sensitive – using rolled titanium square bars with machining allowances can significantly reduce raw material expenses.

- Dimensional consistency and straightness are prioritized – using extruded titanium square bars to reduce subsequent straightening and fine grinding time.

Recommended popular alloy types for titanium square bars

Chalco Titanium offers a wide variety of mainstream titanium alloy square bars, covering diverse applications from general industry to aerospace and medical applications. We support a variety of process routes, including rolling, forging, and extrusion. We offer a wide range of sizes, custom fabrication options, and a stable inventory to meet diverse strength, corrosion resistance, and biocompatibility requirements.

Size: 6 × 6 to 100 × 100

Advantages: Cost-effective, corrosion-resistant and universal, suitable for large quantities

Size: 8 × 8 to 150 × 150

Advantages: High strength and light weight, suitable for high-strength load-bearing and welding

6Al-4V ELI Titanium Square Rod

Size: 6 × 6 to 80 × 80

Advantages: Ultra-low interstitial elements, strong biocompatibility

Gr7 Titanium Square Rod

Size: 10 × 10 to 80 × 80

Advantages: Contains Pd, resists pitting corrosion, and is extremely resistant to chloride ion corrosion

Ti-5553 Titanium Square Bar

Size: 10 × 10 to 100 × 100

Advantages: Ultra-high strength, suitable for heavy-load structures and main load-bearing parts of landing gear

Ti-6242 Titanium Square Bar

Size: 10 × 10 to 100 × 100

Advantages: Strong heat resistance, stable mechanical properties at high temperatures, commonly used in engines

If you need titanium square bars of other alloy types or sizes to meet your actual application needs, please contact us for customization.

Industry solutions and real-world use cases

Marine engineering

Critical components such as structural supports and connectors in offshore platforms and seawater treatment systems are exposed to high chloride ion concentrations over long periods of time, making conventional stainless steel susceptible to pitting corrosion. Titanium square bar, particularly Grade 7 (Ti + 0.15% Pd), offers excellent resistance to chloride ion corrosion, making it an ideal alternative to high-nickel alloys. Compared to welded structures, machined solid square bar provides a more stable structure and significantly extends service life.

Typical parts applications: seawater pump brackets, platform pipe rack connectors, heat exchanger mountings, corrosion-resistant bearing bases, etc.

Real-world case study: In 2020, Huaxiao Alloy supplied 18 tons of Gr 7 titanium square bars (100×100 mm cross-section) to an offshore platform in the Norwegian North Sea. These bars were used for support structures and equipment connections. This batch of products operated under extreme marine conditions for over five years without any pitting, peeling, or structural damage. Subsequent inspection reports confirmed that the bars fully met structural and corrosion resistance requirements, extending their design life by three times.

Medical Devices | High-precision titanium square rods for spinal implants

Titanium square rods, due to their high purity, strong biocompatibility, and precise dimensions, are widely used in the manufacture of connectors, support components, and other structures in spinal implant systems. For these medical products, the material must not only be strong and non-toxic, but also capable of precision machining.

Typical parts applications: spinal implant connection blocks, vertebral support structures, hip joint component blanks

Real-world example: A European medical device manufacturer selected our Gr23 titanium square rod (Ti-6Al-4V ELI) when developing a new spinal fusion brace. They cut the rod and then CNC-machined the connecting modules. The final product achieved a dimensional tolerance of ±0.01 mm and a surface finish that achieved medical-grade finish. The part has successfully passed ISO 13485 and ASTM F136 medical certifications and has been put into clinical use. Customer feedback shows that the product has good adaptability, high processing efficiency, and significantly reduced material waste.

Petrochemical industry

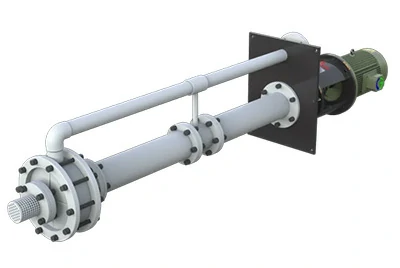

In the petrochemical industry, many pumps and compressors operate for extended periods in high-temperature, highly corrosive environments. Shaft components must possess excellent corrosion resistance, strength, and dimensional stability. Traditional stainless steel is susceptible to corrosion failure in strong acid and chloride ion media, making titanium square rods (particularly Gr2 and Gr5 materials) a more reliable option.

Typical applications: chemical pump main shaft, rotary sealing shaft, compressor connection block, etc.

Real-world cases: After replacing their original stainless steel pump shafts with Gr5 titanium square rods (Pump Shaft Quality) provided by Chalco Titanium, several customers have extended their pump service life from 2–3 years to over 8 years, effectively reducing downtime and replacement costs. Titanium square rods maintain high strength while exhibiting exceptional resistance to acidic and chlorine-containing media, making them suitable for a wide range of continuous production systems.

For integrated engineering projects, we also supply round titanium bars, flat bars, and hexagonal bars in various grades and specifications. By combining different titanium bar profiles within the same material system, customers can streamline procurement, ensure structural compatibility, and optimize machining efficiency. Whether your project requires square sections for structural support or round and hex bars for rotating and precision components, we provide coordinated supply solutions to support complete project implementation.

Manufacturing supporting services and delivery guarantee

Strict quality inspection to ensure that each piece is qualified before leaving the factory

Every batch of titanium square bars undergoes rigorous testing before shipment, including dimensional accuracy, surface defects, mechanical properties, chemical composition, and ultrasonic testing (UT). Upon request, we can provide third-party testing reports based on ASTM B348 and AMS specifications to ensure that our products meet design and performance requirements.

Supports multiple secondary processing, saving time and worry

We can provide basic processing services such as sawing, turning, drilling, and milling. Titanium square bars can be sized, chamfered, or pre-processed into specific structural shapes according to customer requirements, helping customers shorten assembly cycles and reduce waste. They are particularly suitable for the prototype stage before mass production.

Optional surface treatment process to meet different usage scenarios

Titanium square bars can be treated with pickling, sandblasting, and mechanical polishing to improve surface finish or enhance corrosion resistance. For specialized applications (such as medical and offshore), custom anodizing or protective coatings can be applied to enhance overall performance and durability.

Safe packaging and export transportation, so you can receive the goods with confidence

Each titanium square bar is packaged in a rust-proof film, foam, and wooden crate, suitable for sea, air, and express shipping. All export materials are laser-coded and labelled with compliance labels. We support FedEx/DHL express delivery, small-volume air freight, and full container ocean freight, ensuring on-time delivery worldwide.

Quality Inspection

Processing

Package

FAQ

Can you provide material reports and original melt traceability information?

Chalco Titanium provides comprehensive material testing reports (e.g., EN 10204 3.1), including chemical composition, mechanical properties, and ultrasonic testing. All titanium square bars are batch-numbered and traceable back to the original melting furnace, meeting the traceability requirements of industries such as aerospace and medical.

How long is the delivery cycle?

In-stock orders are typically shipped within 3–5 business days; custom orders vary in size and quantity, with lead times typically ranging from 10–25 days.

Can you customize the length, slotting, chamfering and other processing?

We can provide secondary processing services such as cutting, chamfering, drilling, and milling according to customer drawings. These services are suitable for proofing and pre-processing of small batches of structural parts, eliminating the cost of reprocessing for customers.

Is it okay to purchase a small batch for testing? What is the MOQ?

We support small batch orders, with the minimum order quantity for regular specifications as low as 1 piece, which is suitable for customers to do performance testing, sample verification or project trial production.

Is the export packaging secure? How can we prevent scratches or oxidation during transportation?

Each titanium square bar is wrapped in rust-proof film and foam cushioning before leaving the factory. It is then packed in reinforced plywood crates suitable for shipping by sea, air, or courier. Customizable packaging solutions are available and meet international export standards.

Is titanium square bar easy to stick to the knife during processing? How to deal with it?

Titanium does present machining challenges, such as tool sticking and poor thermal conductivity. We recommend using carbide tools, slow, heavy cutting with adequate cooling, and, when necessary, titanium-specific cutting fluids, while maintaining stable equipment.

Can you quote by weight, or by root/meter? Can you package the whole order?

We offer quotes by weight (kg), number of pieces, or length (meters), allowing us to flexibly meet customer needs. We offer comprehensive discounts for bulk orders, with a total price calculated based on the entire order. We also support a variety of trade terms including EXW, FOB, and DDP.

Get exclusive titanium square bar processing and procurement solutions

Chalco Titanium offers titanium square bar products in a variety of grades and finishes, covering a full range of applications from general industrial to aeromedical grades. Custom sizes, tolerances, and surface finishes are available, along with material certification and processing recommendations to help you efficiently complete project development and production. Contact us for technical support and a quick quote.