Grade 12 Titanium Sheet

Grade 12 Titanium Sheet/Plate, also known as Ti-0.3Mo-0.8Ni (UNS R53400), is a low-alloy, corrosion-resistant titanium material. Compared to conventional Grade 2, it performs better in chloride-containing and reducing acid environments while maintaining good weldability and formability. It is often used as a cost-effective alternative to Grade 7 palladium-alloyed titanium in the chemical, offshore, and energy industries.

- Excellent corrosion resistance: Outstanding performance in reducing acids and chloride-containing environments.

- Cost-effective: Performance close to Grade 7 at a lower cost.

- Standards compliance: Complies with ASTM B265 / ASME SB-265 and provides traceable Material Traceability Certificate (MTC).

Technical Specifications and Performance Indicators

Standards & Certifications

Grade 12 titanium sheet/plate strictly adheres to international standards and can be directly used in key industries such as chemical processing, desalination, and flue gas desulfurization (FGD). We provide material certification (MTC) and complete batch traceability documentation to help customers quickly complete compliance verification.

- ASTM B265 / ASME SB-265: Specification for Titanium and Titanium Alloy Plate, Strip, and Sheet

- ASTM B338 / ASME SB-338: Standard for Titanium Tubing for Heat Exchangers and Condensers (Titanium Coil and Welded Tubing)

- ASTM B861 / B862: Standard for Titanium and Titanium Alloy Seamless and Welded Tubing

- UNS R53400: Grade 12 International Unified Designation

- AMS 2631: Ultrasonic Inspection of Titanium and Titanium Alloy Bars, Billets, and Plates

Grade 12 Titanium Chemical Composition

| Elements | Content Range |

|---|---|

| Ni | 0.60–0.90 |

| Mo | 0.20–0.40 |

| O | ≤0.25 |

| Fe | ≤0.30 |

| C | ≤0.08 |

| N | ≤0.03 |

| H | ≤0.015 |

| Ti | Residue |

Grade 12 Titanium Physical Properties

| Specifications | value |

|---|---|

| Density | 4.51 g/cm³ |

| Elastic Modulus | 103–105 GPa |

| Thermal Conductivity | 19 W/m·K |

| Coefficient of Linear Expansion (CTE, 20–100°C) | 8.6 ×10⁻⁶ /K |

| Melting Point | 1660–1668 °C |

Mechanical Properties of Ti-0.3Mo-0.8Ni Titanium

| Performance Indicators | value |

|---|---|

| Ultrasonic Strength (UTS) | ≥ 483 MPa (70 ksi) |

| Yield Strength (YS, 0.2%) | ≥ 345 MPa (50 ksi) |

| Elongation | ≥ 18 % |

| Bend Radius | 2T – 2.5T |

Specifications of Grade 12 Titanium Sheet

| Specifications | Range / Options |

|---|---|

| Thickness | 0.5 mm – 60 mm, custom sizes available |

| Width | 400 mm – 2500 mm |

| Length | 1000 mm – 6000 mm, cut-to-size available |

| Tolerance | Complies with ASTM B265 / ASME SB-265 requirements, customizable |

| Delivery Condition | Annealed (M) |

| Surface Finish | Pickled, Bright, optional with protective film |

| Packing | Vacuum-proof + wooden or steel box mounting, suitable for sea or land transport |

| Material Traceability | EN 10204 3.1 / 3.2 MTC, marked with grade, standard, and heat number |

Related Products

Grade 12 Titanium Coil

Rolled from Grade 12 titanium sheet into coils, it enables continuous processing and transport, ideal for welded tubes and high-volume applications.

Grade 12 Ti Welded Tube

Welded from Grade 12 titanium coils to ASTM B862, widely used in heat exchangers and chemical piping for corrosion resistance and cost-effectiveness.

Grade 12 Ti Tube Sheet

Precision-machined from Grade 12 titanium sheet, widely used in heat exchangers and performing well with titanium tubes in chlorine and reducing acid environments.

By organically combining titanium plates, titanium coils, welded tubes, and tube sheets, we can not only provide a single material, but also deliver a complete set of supporting forms, helping customers reduce procurement costs and improve engineering consistency and reliability.

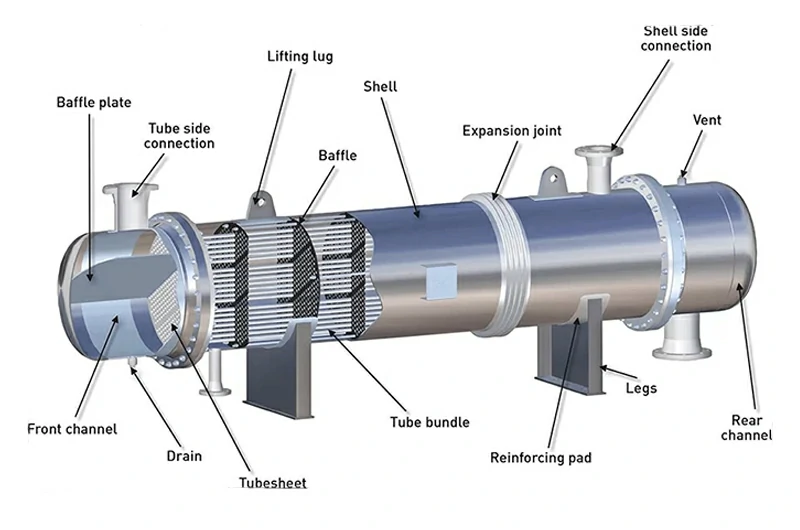

Heat Exchanger System Solutions

In the chemical, desalination, and flue gas desulfurization (FGD) industries, heat exchanger equipment is exposed to chlorine-containing and acidic media for extended periods, placing extremely high demands on materials. Grade 12 titanium alloy (Ti-0.3Mo-0.8Ni, UNS R53400), with its excellent corrosion resistance and weldability, is an ideal material for critical heat exchanger components.

Tube Bundles & U-tubes:

Grade 12 titanium tubes (ASTM B338/B862) resist pitting and crevice corrosion in condensers and evaporators, ensuring efficient heat transfer and long service life.

Tube Sheets:

Drilled from Grade 12 plate, offering strong crevice corrosion resistance and stable tube-to-sheet welding for large bundles.

Shells & Linings:

Made from Grade 12 sheet/coil or as linings, providing durable protection and extending equipment life.

Heads & Baffles:

Heads and baffles exposed to corrosive media can also be manufactured from Grade 12 titanium plate, ensuring overall corrosion resistance while maintaining fluid distribution and mechanical support. Grade 12 titanium alloy provides a complete material solution for heat exchangers, encompassing key components such as tube bundles, U-tubes, tube sheets, shells, liners, headers, and baffles, helping customers achieve long-term, stable operation in highly corrosive environments. For more in-depth industry solutions, please refer to our Titanium Heat Exchange System Solutions.

Typical Applications of Grade 12 Titanium Plate

In addition to its widespread use in various heat exchanger systems, Grade 12 titanium plate also boasts unique resistance to reducing acids and chloride-containing environments. It is widely used in a variety of industries, including chemical, energy, offshore, and electroplating, providing customers with high material reliability.

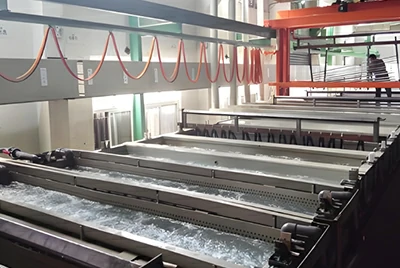

Chemical Pickling Tanks and Reaction Equipment

Use: Grade 12 titanium plates for pickling tanks, reactors, and tank walls.

Features: Resist pitting and crevice corrosion in HCl and H₂SO₄, extend service life.

Desalination Evaporators and Condensers

Use: Tubesheets and linings of Grade 12 titanium plates in high-chloride brine.

Features: Gr7-level corrosion resistance at lower cost, ideal for large desalination plants.

Flue Gas Desulfurization (FGD) Tower Lining

Use: Grade 12 titanium plates as linings in coal-fired power plant towers.

Features: Strong acid resistance, ensuring stable long-term operation.

Through successful applications in typical applications such as pickling equipment, seawater desalination heat exchangers, and FGD tower linings, Grade 12 titanium plate has demonstrated its unique advantages of "corrosion resistance and high cost-effectiveness," providing customers with a reliable and long-lasting material solution.

Advantages and Comparisons of Grade 12 Titanium Plate

Material selection not only affects the initial purchase cost but also determines the lifespan and maintenance costs of equipment in harsh environments. The following comparison table clearly illustrates the differences between Grade 12 titanium plate and more common materials.

Grade 2 vs. Grade 7 vs. Grade 12

| Comparison Items | Grade 2 | Grade 7 | Grade 12 |

|---|---|---|---|

| Corrosion Resistance | Good, but performance is insufficient in dilute hydrochloric acid, dilute sulfuric acid, and chloride ion environments. | Excellent, especially for environments with strong chloride ions and acids | Close to Grade 7, significantly better than Grade 2, with outstanding performance in pitting and crevice corrosion. |

| Cost | Low | High (due to palladium content) | Medium |

| Service Life | Medium | High | High |

| Weldability | Excellent | Excellent | Excellent |

| Typical Operating Conditions | Conventional chemical and seawater environments | Effective for applications requiring extreme corrosion and high lifespan | Suitable for highly corrosive environments such as chlorine-containing acidic media, FGD, and desalination. |

- Grade 2 is suitable for general chemical and seawater environments, benefiting from its low price. However, it performs poorly in reducing acids such as dilute hydrochloric acid and dilute sulfuric acid.

- Grade 7 is one of the most corrosion-resistant titanium materials, but it is more expensive. It is suitable for projects with ample budgets and extreme life requirements.

- Grade 12 performs similarly to Grade 7 in conditions like pitting and crevice corrosion, yet maintains a lower cost, making it the optimal balance for most corrosive environments.

Titanium vs. Stainless Steel vs. Nickel Alloy

| Comparison Items | Stainless steel | Nickel alloys | Grade 12 Titanium Plate |

|---|---|---|---|

| Corrosion Resistance | Susceptible to pitting and stress corrosion cracking in chloride ions and dilute acids | Good corrosion resistance, but limited in strong chloride environments | Excellent performance in dilute hydrochloric and sulfuric acids, as well as in chlorine-containing media |

| Cost | Low | High | Medium |

| Service Life | Medium-low, requires frequent maintenance | Medium-high, but heavier | High, minimal maintenance |

| Weight | Heavy | Heavier | Lightweight (density 4.51 g/cm³) |

| Life Cycle Cost (LCC) | Surface-cheap, but frequent maintenance and replacement lead to high overall costs | Very high initial cost, moderate maintenance | Moderate purchase cost, long service life, and lowest total cost of ownership |

- Stainless steel has a limited lifespan in chloride or acidic environments, requiring low short-term investment but requiring frequent long-term maintenance, resulting in higher overall costs.

- Nickel alloys offer excellent corrosion resistance, but are extremely expensive and heavy, hindering lightweighting and cost control.

- Grade 12 titanium plate combines lightweight, high corrosion resistance, and a long lifespan, offering moderate procurement costs and the lowest overall lifecycle cost.

Compared with Grade 2, Grade 7, stainless steel, and nickel alloys, Grade 12 titanium plate clearly demonstrates its unique advantages: near-high-end performance, significantly better cost, and a lifespan far exceeding that of traditional metals. It is the optimal material for achieving a balance between performance and cost in engineering projects.

Chalco - High-Quality Titanium Plate Supplier

- Advanced Equipment: Precision rolling and heat treatment lines ensure flatness and consistency.

- Strict Certification: Certified to AS9100/ISO9001, full MTC and traceability.

- Full Range of Specifications: 0.5–120 mm thickness, custom cuts available.

- Delivery Certainty (SLA): Fast shipment and flexible scheduling.

- Total Cost of Ownership (TCO): Dimensional precision reduces costs, full lifecycle support provided.

FAQ

What are the main differences between Grade 12 titanium plate and Grade 2 and Grade 7?

Grade 12 offers superior corrosion resistance compared to Grade 2 and performs similarly to Grade 7 at lower cost.

What international standards does Grade 12 titanium plate comply with?

ASTM B265/ASME SB-265, EN 10204 3.1/3.2 MTC, meeting requirements for chemical, desalination, and FGD projects.

What heat exchanger components can Grade 12 titanium plate be fabricated into?

Tube sheets, shells, linings, heads, and baffles, widely used in evaporators and condensers.

What sizes of Grade 12 titanium plate are currently in stock?

Thickness 0.5–60 mm, widths 1000/1219/1500 mm, lengths 2000–6000 mm, custom cuts available.

Why choose Chalco as your supplier of Grade 12 titanium plate?

Chalco offers advanced facilities, certification, comprehensive inventory, and lifecycle support with cost reduction advantages.