Titanium Angle

Titanium angle steel, also known as titanium L-shaped profiles or titanium angle aluminum, is a structural profile with a 90-degree angle. It is widely used in load-bearing structures, connecting brackets, reinforcing frames, and various corrosion-resistant applications. Compared to aluminum or stainless steel, titanium offers a higher strength-to-weight ratio and superior corrosion resistance, making it suitable for extreme working environments, offering a longer lifespan, and a more cost-effective solution.

Certifications provided by Chalco Titanium

To meet the compliance requirements of global customers in the aerospace, marine and industrial sectors, Chalco Titanium provides the following certifications and documentation to support project review, quality assessment and customs clearance:

- EN 10204 3.1 / 3.2

- RoHS & REACH

- AS9100

- ISO 9001

If you have any specific certification, third-party testing (such as SGS, BV, TÜV) or project review document requirements, please leave a note when placing an order and we will fully cooperate.

Popular grades of titanium angle

Titanium angle steel is a structural profile widely used for support, connection, reinforcement and other purposes. Different grades of titanium have differences in strength, corrosion resistance and weldability, which makes them have their own advantages in different structural scenarios. The following are several commonly used and popular titanium angle steel materials:

-

Gr2 Titanium Angle Moderate strength, excellent corrosion resistance, and good weldability. Suitable for structures with high corrosion resistance requirements but medium loads, such as offshore platform supports, chemical plant support structures, and medical clean room frames.

-

Gr5 Titanium Angle High strength and lightweight, suitable for load-bearing structures. Widely used in aviation equipment brackets, racing car frames, bicycle structural connectors and other parts with high requirements for both weight and strength.

-

Gr7 Titanium Angle Steel Based on Gr2, it has enhanced corrosion resistance in chlorine-containing environments. It is suitable for chlorine treatment equipment support frames, seawater desalination device frames, and coastal structure anti-corrosion reinforcement support parts.

-

Gr12 Titanium Angle It has both corrosion resistance and medium strength, and is particularly suitable for use in environments where thermal stress and corrosion coexist, such as heat exchanger pipe racks, steam system supports, and heat exchange station structural components.

Chalco also offers custom L-profiles in titanium alloys such as Gr9 and Gr23 for special load, temperature, or corrosion resistance requirements. Contact us for recommendations and samples. Get a quick quote .

Types of titanium angles provided by Chalco Titanium

According to the needs of different structural scenarios and installation methods, Chalco Titanium provides the following types of titanium angle steel to meet the requirements of different fields.

Equilateral titanium angle steel

The two sides are equal in length, the cross-section is a standard L-shape, the structure is stable, and it is suitable for most conventional brackets, connectors and welding reinforcement scenarios.

Contact us now

Unequal titanium angle steel

The two sides are of unequal length, which is suitable for structures with limited space, uneven force or eccentric installation, such as equipment edge reinforcement, angled support, etc.

Contact us nowRounded titanium angle steel

The inner or outer corners have rounded transitions to reduce stress concentration and are suitable for structural parts with vibration, temperature difference or high fatigue requirements.

Contact us now

Customized special-shaped titanium angle steel

Special sections can be customized according to drawings, such as structures with beveled edges, punching, grooving, polygonal combinations, etc., to adapt to complex installation or special mechanical requirements.

Contact us nowChalco offers in-stock titanium angle steel with equal legs. We also support rapid mold creation and customization for unequal legs and special shapes. For special drawings or project requirements, please contact us for solutions.

What are the advantages of titanium angle steel?

Excellent corrosion resistance

Gr2 and Gr7 titanium angle steels can last for more than 10 years in seawater, chloride, high humidity, acid and alkali environments without replacement; compared to 304/316 stainless steel, the corrosion rate is one order of magnitude lower and is almost maintenance-free.

High strength to weight ratio, suitable for replacing steel structures to reduce weight

Gr5 titanium angle steel boasts approximately twice the strength of Q235 carbon steel, yet only 56% of its density. While maintaining the same load requirements, it can reduce structural weight by 40% to 50%. It is widely used in high-strength, lightweight applications such as aviation brackets and racing frames.

Weldable and machinable, easy to connect with other structures

Titanium angle steel can be structurally spliced using TIG welding and titanium-specific welding wire (such as ERTi-2/ERTi-5). Conventional sawing, water jet cutting, and CNC processing are also applicable, facilitating later assembly and customization.

Non-magnetic

The non-magnetic properties make titanium angle steel the first choice for frame supports of MRI medical equipment and radar electronic equipment. Replacing carbon steel can eliminate the risk of magnetic interference.

Low thermal expansion coefficient and more stable structure

The thermal expansion coefficient of titanium is approximately 60% of that of stainless steel. It can maintain better dimensional and connection stability in environments with drastic temperature changes (such as outdoors and steam system brackets), reducing deformation due to thermal expansion and contraction.

Strong fatigue resistance

The fatigue strength of titanium is higher than that of aluminum alloy and stainless steel, and it is particularly suitable for vibration and cyclic load conditions, such as ships, mechanical equipment frames, bridge nodes and other long-term operating structures.

Dimensional parameters and tolerances

Size range

Chalco Titanium offers titanium angles in a variety of sizes and specifications, suitable for a wide range of engineering needs, from light supports to medium- and heavy-duty structural components:

- Leg Length : 20 × 20 mm to 100 × 100 mm

- Wall Thickness : 2.0 mm to 10.0 mm

- Profile Length : Standard lengths are 2000 mm / 3000 mm / 6000 mm, and cut-to-length is supported .

Chalco Titanium offers a wide range of commonly used stock sizes for titanium angles, including various equal and unequal leg sizes, to meet customers' needs for rapid selection and delivery for diverse applications, including structural support and joint reinforcement. For detailed stock lengths, thicknesses, and length combinations, please click below to view the size chart .

Tolerance Description

The machining accuracy and structural stability of titanium angle steel are particularly critical for assembly. Chalco can control the following tolerance ranges according to different usage scenarios:

- Angle tolerance : 90° ±1° , can be corrected as needed

- Straightness : ≤ 1.0 mm/m (conventional standard), stricter standards can be customized

- Side length tolerance : ±0.5 mm (refer to ASTM B348 / AMS 4928 standards)

- Wall thickness tolerance : ±0.2 mm to ±0.5 mm, depending on extrusion size and thickness

We offer custom processing services such as grinding, straightening, and non-standard chamfering to meet precision assembly needs . For tighter tolerances (for applications in aviation, medical, and other fields), please provide drawings or technical specifications, and we will tailor a process solution.

Added services that Chalco Titanium can provide

To help customers improve assembly efficiency, reduce processing costs, and accelerate project progress, Chalco Titanium provides one-stop value-added processing and supporting services for titanium angle steel, covering the following aspects:

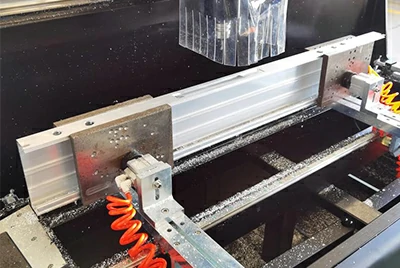

Processing services

- Supports cutting to length according to drawings or specified lengths, with high tolerance control accuracy, facilitating quick installation on site.

- We provide drilling, tapping and grooving services, which are suitable for pre-assembly of structural connections, reducing the customer's post-processing steps.

- Angle correction and edge chamfering can be performed to improve structural fit and installation safety.

- Provide high-precision CNC machining services to meet the customized needs of special-shaped structures and complex interfaces.

Surface treatment

- By pickling or descaling, the surface oxide layer formed by extrusion is removed to improve the overall cleanliness.

- Sandblasting or matte finishing can make the surface texture uniform, enhance the appearance and scratch resistance.

- Polishing and fine grinding are suitable for structural parts with high requirements on surface finish and dimensional accuracy.

- Provide anodizing and surface coloring services, which can present black, gold, blue and other colors for functional identification or brand customization

Export packaging and exclusive logistics solutions

- We provide customized packaging solutions (moisture-proof, shock-proof, and corrosion-proof) according to different markets and transportation methods (air /sea).

- label printing services such as customer logos, product codes, packing lists, etc.

- A variety of delivery methods are available: FOB / CIF / DAP / DDP, flexible delivery to suit customer project schedules.

Global project supporting capabilities

- We have long-term service to project-based clients in Europe, America, Japan, South Korea, the Middle East, and Southeast Asia, and are familiar with overseas project documents and delivery processes.

- Provide one-on-one communication with engineers to help overseas customers successfully pass project review and quality system acceptance.

Which process is right for your titanium angle steel project?

Titanium angles can be formed using a variety of manufacturing processes, each suited to different dimensional, tolerance, production volume, and budget requirements. Chalco Titanium offers a variety of production paths to help you balance performance, cost, and delivery schedules.

Die extrusion molding

Titanium ingots are extruded through specialized dies at high temperatures to form continuous, uniformly shaped L-shaped profiles. This process is highly efficient and produces sharp edges and corners. Subsequent straightening, cutting, and heat treatment ensure strong dimensional stability.

Selection suggestion: If you need large quantities of equal or unequal-sided titanium angle steel with consistent side length and good surface consistency, we recommend extrusion molding, which is suitable for standardized applications such as aviation, medical, and mechanical frames.

Hot rolling/hot bending

This process is performed by pressing or bending the heated titanium blank into a desired shape. It is suitable for structural parts with thicker sections or non-standard angles. This process is highly flexible and suitable for small batches and custom projects, but its surface and angle accuracy is slightly lower than that of extrusion.

Selection suggestion: If your project involves thick-walled structures, non-90° angles, or does not require high appearance consistency, hot rolling or hot bending processes can be used, which are more cost-effective and suitable for scenarios such as engineering brackets and heat exchange equipment structures.

Custom mold making

Titanium angles with special cross-sections, compound angles, holes, or beveled edges can be extruded using custom molds. Chalco can assist with rapid mold development and provide technical confirmation and prototyping services.

Selection suggestion: If your structural design is special and needs to match specific equipment or installation interfaces, it is recommended to provide drawings. We will develop a customized mold plan for you to ensure that the molded structure is highly compatible with the installation environment.

Related product recommendations

If your project requires other structural profiles, we can also provide them:

FAQ

What is the minimum bending radius of titanium angle steel?

It is generally recommended that the minimum bending radius be 3 times or more of the material thickness to avoid cracking or deformation. For thick-walled titanium angle steel or high-stress applications, hot bending or preheating is recommended to ensure structural integrity.

Can titanium angle steel be welded to stainless steel?

Yes, but you need to use titanium-compatible welding wire (such as the ERTi series) and use an inert gas (such as argon) to prevent oxidation during welding. After welding, the dissimilar metals should be electrochemically isolated to avoid galvanic corrosion.

What are the advantages of titanium angle steel over fiberglass reinforced plastic (FRP) or aluminum profiles?

Titanium has a higher strength-to-weight ratio, natural corrosion resistance, and excellent high-temperature resistance. Its lifespan under long-term loads, marine, or highly corrosive environments far exceeds that of FRP or aluminum, making it more suitable for use in critical structures.

Can titanium angle steel be used for outdoor long-term structures?

Absolutely. The self-passivating oxide film on the surface of titanium can resist erosion from rain, salt spray, acidic gases, etc., and requires no spraying or maintenance. It is often used in structural support components in coastal buildings, offshore platforms and chemical plants.

Can titanium angle steel be subjected to secondary processing, such as welding or drilling?

Supports conventional cutting, drilling, tapping, welding and other processes. It is recommended to use special tools and lubrication and cooling systems for machining, while controlling the heat-affected zone to ensure stable performance after welding.

Do you support small batch orders or sample trials?

Chalco Titanium offers a small order quantity service. Free samples of regular sizes in stock can be provided for size verification, process testing or trial installation, reducing the customer's early development risks.

What certifications can the titanium angle steels provided by Chalco pass?

We can provide EN 10204 3.1 / 3.2 material reports on demand, support RoHS, REACH, AS9100, ISO 9001, CE and other certifications, and assist customers with project reviews and international customs clearance.

Chalco Titanium angle stock sizes

Chalco Titanium offers a full range of titanium angle steel products, covering two categories: equal-leg titanium angle steel and unequal-leg titanium angle steel , with a full range of specifications, suitable for a variety of engineering needs from light supports to medium and heavy structural parts.

The product side length ranges from 20 × 20 mm to 100 × 100 mm , the wall thickness ranges from 2.0 mm to 10.0 mm , and the standard supply length is 2000 mm / 3000 mm / 6000 mm . It also supports on-demand cutting to meet customers' diverse application scenarios.

Equilateral titanium angle steel

| Side length (mm × mm) | Wall thickness (mm) | type | Optional length (mm) |

|---|---|---|---|

| 20 × 20 | 2.0 / 3.0 / 4.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 25 × 25 | 2.0 / 3.0 / 4.0 / 5.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 30 × 30 | 2.0 / 3.0 / 4.0 / 5.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 35 × 35 | 2.5 / 3.0 / 4.0 / 5.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 40 × 40 | 3.0 / 4.0 / 5.0 / 6.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 45 × 45 | 3.0 / 4.0 / 5.0 / 6.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 50 × 50 | 3.0 / 4.0 / 5.0 / 6.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 60 × 60 | 4.0 / 5.0 / 6.0 / 8.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 65 × 65 | 4.0 / 5.0 / 6.0 / 8.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 70 × 70 | 4.0 / 5.0 / 6.0 / 8.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 75 × 75 | 5.0 / 6.0 / 8.0 / 10.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 80 × 80 | 5.0 / 6.0 / 8.0 / 10.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 90 × 90 | 6.0 / 8.0 / 10.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

| 100 × 100 | 6.0 / 8.0 / 10.0 | Equilateral | 2000 / 3000 / 6000, can be cut to length |

Unequal titanium angle steel

| Side length (mm × mm) | Wall thickness (mm) | type | Optional length (mm) |

|---|---|---|---|

| 30 × 20 | 2.0 / 3.0 / 4.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 40 × 25 | 2.5 / 3.0 / 4.0 / 5.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 50 × 30 | 3.0 / 4.0 / 5.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 60 × 40 | 3.0 / 4.0 / 5.0 / 6.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 70 × 50 | 4.0 / 5.0 / 6.0 / 8.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 80 × 60 | 4.0 / 5.0 / 6.0 / 8.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

| 100 × 75 | 5.0 / 6.0 / 8.0 / 10.0 | unequal sides | 2000 / 3000 / 6000, can be cut to length |

If you don't see the size or wall thickness you need in the specifications above, Chalco Titanium can provide custom titanium angles . We offer custom sizes, special lengths, and surface treatments. Contact our engineering team for a personalized solution and quote.