Titanium I Beam

In structural scenarios requiring high strength, light weight and extreme corrosion resistance, Titanium I Beam is rapidly becoming the material of choice in aerospace, marine engineering, high-end construction and chemical equipment manufacturing.

Titanium I Beam features an I-shaped cross-section structure, combining excellent load-bearing capacity with outstanding material conservation. It is particularly suitable for projects with long spans or harsh environments that have strict requirements on strength and weight control.

If you are looking for a load-bearing profile that combines structural safety, lightness, and durability, the Titanium I Beam is a reliable solution.

As a professional titanium manufacturer and global supplier, Chalco Titanium offers a complete range of solutions, from standard stock specifications (3″–12.31″) to custom extrusions and CNC precision machining. Whether used for aerospace structures, offshore wind turbine jackets, or chemical equipment frameworks, we provide rapid response and precise matching to meet stringent structural and corrosion protection requirements.

Recommended common titanium alloy types

Titanium I Beam is available in a variety of alloys for different applications. The following two are the most popular grades on the market, widely used in industries such as aviation, offshore engineering, chemicals, and construction .

We also offer other specialized titanium alloys upon request, such as Grade 7 (palladium alloy, suitable for high-corrosion environments), Grade 23 (medical-grade Ti-6Al-4V ELI), and Ti-6242, suitable for high-temperature aerospace parts. If you have specific material standards or application requirements, please feel free to contact us for customization. Our engineering team will provide alloy selection advice and technical support.

-

Grade 2 Titanium I Beam Grade 2 is pure titanium with excellent corrosion resistance, good ductility, and easy weldability, making it ideal for seawater, chemical gases, offshore platforms, and exposed structures.

-

Grade 5 Titanium I Beam (Ti-6Al-4V) Grade 5 is an α+β titanium alloy with very high strength and excellent fatigue resistance, with tensile strength up to 895 MPa. It’s ideal for lightweight, high-strength applications like aviation structures, wind turbine supports, and landing gear beams.

The alloy selection recommendations are as follows:

- If your project is located near the sea or offshore, or involves corrosive media such as salt water, alkali, or industrial gases, we recommend Grade 2 industrial pure titanium, which offers both corrosion resistance and cost advantages.

- If you are facing high loads, dynamic impact or structural environments that require extremely high strength support, such as aviation, wind power or heavy machinery structures, Grade 5 (Ti-6Al-4V) is recommended to achieve greater load-bearing capacity at a lighter weight.

If you are unsure which material is best for your project, please send us your drawings or working conditions. We will provide you with alloy selection recommendations and technical quotation support to ensure the optimal match between performance, safety and cost.

Popular titanium beam sizes are available directly from stock

Chalco Titanium offers a wide range of Titanium I -beams in stock , meeting diverse needs, including rapid procurement, urgent project delivery, and sample installation. Our inventory covers cross-sections from 3" to 12.31", wall thicknesses from 3 mm to 120 mm, and standard lengths from 3 to 6 meters. We also support custom cut-to-length (up to 9 meters), meeting diverse structural strength and installation requirements for diverse projects.

In-stock materials cover Grade 2 and Grade 5, and some specifications have been pickled, sandblasted, or rough-finished. They can be shipped within 24 hours at the earliest, making them particularly suitable for customers with tight project deadlines who don't need to wait for extrusion dies.

For detailed dimensions, stock quantities and lead times, please click to view our latest stock details .

Why customers are keen on titanium I beam?

- The I-section design can resist bending and shear to the greatest extent, concentrate stress on the flange, and has high material utilization, making it suitable for large-span and high-load scenarios.

- Titanium has a density of only 4.51 g/cm³, which is about 60% of that of steel. It significantly reduces the weight of the overall structure while maintaining its strength. It is particularly suitable for weight-sensitive projects such as aircraft, ships, and bridges.

- Grade 5 titanium beams have a tensile strength of up to 895 MPa. When combined with the I-type structure, they provide superior strength performance per unit weight compared to traditional steel beams.

- Whether it is industrial acid and alkali, seawater, salt spray or chloride ion environment, titanium can work stably for a long time and almost no additional anti-corrosion treatment is required.

- Compared with aluminum or stainless steel, titanium has a lower thermal expansion coefficient and can maintain good dimensional stability under high temperature and hot and cold cycle conditions, reducing structural deformation.

- Titanium beams can be used in harsh environments such as marine and chemical industries for more than 15-25 years without replacement, effectively reducing operation and maintenance frequency and full life cycle costs.

Industry solutions and practical application cases

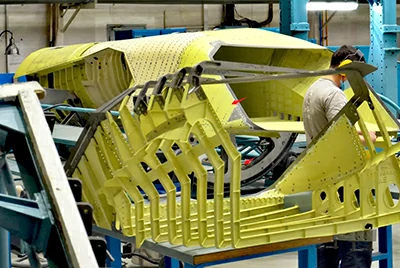

Aerospace

In aviation manufacturing, structural weight reduction is always a core goal. Titanium I -beams, with their high strength-to-weight ratio and excellent fatigue performance, are widely used in load-bearing components such as wing spars and landing gear main beams.

Case study : In a US project, the customer used Grade 5 extruded titanium beams to replace steel structures, reducing overall weight by 38% while extending the aircraft's service life by approximately 15%.

Offshore wind power

Offshore wind turbine jackets and platform structures are constantly exposed to high salt spray, high humidity, and high chloride ion concentrations. Traditional steel is susceptible to corrosion and has high maintenance costs. Titanium I -beams offer excellent corrosion resistance and are particularly suitable for use in intertidal zones or fully submerged areas.

Actual case : In a wind power project in the North Sea of the UK , the customer chose titanium I- beams to replace carbon steel structures. After 18 months of field service testing, there was no pitting on the surface and the structure was intact.

Building curtain wall and bridge structure

Modern high-rise buildings pursue a high degree of integration between lightweight structure and exterior design. Titanium I -beams not only offer high strength and low weight, but also allow for surface polishing and precision customization, making them suitable for structures such as glass curtain wall supports and aerial bridges.

Actual case : In a high-end commercial building project in Singapore, the client used titanium beams to make the main body of the bridge, with the surface mirror-polished to Ra 0.4 and customized end fillets to balance aesthetics and strength.

Chemical equipment and corrosion-resistant load-bearing structures

The load-bearing structures of chemical plant equipment are often exposed to high temperatures and alkaline environments, placing extremely high demands on the material's corrosion resistance and stability. Titanium, with its NaOH corrosion resistance and strong thermal stability, is an ideal long-term solution.

Actual case : In a large caustic soda plant project in Brazil, the customer used Grade 2 titanium I -beams as the equipment frame structure, which operated in a 120°C alkaline steam environment for 10 years without corrosion.

What can Chalco Titanium do for you?

Surface treatment

Depending on the application environment and project requirements, Titanium I -beams can provide a variety of surface treatments to improve corrosion resistance, aesthetics, or compatibility with subsequent processing. We support the following common treatment processes:

- Pickling and passivation treatments can effectively remove surface oxide scale and impurities, improving corrosion resistance and surface purity. They are usually performed according to ASTM B600 or AMS process specifications and are suitable for titanium beams used in harsh environments such as marine and chemical industries.

- Sandblasting (surface cleanliness up to Sa 2.5) provides a uniformly rough surface, which facilitates the adhesion of subsequent anti-corrosion coatings. It is widely used in offshore structures and engineering projects requiring the NORSOK M-501 coating system.

- Precision mechanical polishing or grinding can control the surface roughness to Ra ≤ 0.4–0.8 µm, which is suitable for scenes such as building curtain walls and medical frames that have high requirements for appearance and connection surfaces .

- Anodizing is mainly used to form a stable oxide film or color code identification. It is used as light protection or identification mark in aviation, medical and electronic structures. It is not recommended for primary corrosion protection purposes.

- Customized processing is also supported, including micro-sandblasting, rough surface, ceramic coating, high-temperature resistant fluorocarbon coating, etc. All special surface conditions can be processed and delivered according to drawings or standard requirements.

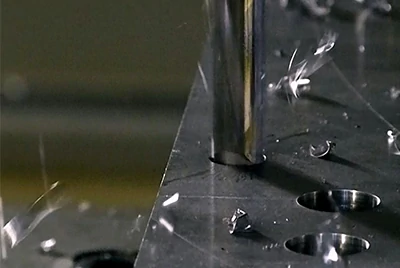

Introduction to secondary processing capabilities

To meet the diverse needs of clients across various industries for structural dimensions, interface styles, and assembly accuracy, Chalco Titanium offers comprehensive titanium I- beam secondary processing services, encompassing cutting, welding, drilling, end machining, and other processes, tailored to the project 's immediate needs.

- We offer ±0.2 mm high-precision CNC sawing and cut-to-length processing services, supporting cutting lengths from 100 mm to 9 m, meeting the flexible needs of samples, small batches, or extra-long structures.

- For structural connection parts, end milling, groove processing and customized chamfering can be performed to ensure that the flatness of the installation surface and the reserved space for welds meet the design requirements.

- Provide drilling and slotting processing, support standard hole positions, countersunk holes and long slot designs, and the hole diameter tolerance can be controlled within ±0.1 mm, suitable for precision assembly or structural screw connection.

- For welded parts, we have the ability to perform Grade 2 and Grade 5 titanium alloy TIG welding and electron beam welding. The welding process is fully protected by argon gas. We can also issue WPQR or third-party inspection reports upon request.

- For special-shaped interface projects, we can provide water jet /laser cutting services to achieve complex end profiles, such as arc, dovetail, serrated edge and other connection structures.

Packaging services

- All titanium I-beams are packed in custom-sized thick-walled wooden boxes or steel -sided boxes to ensure stable load-bearing, impact resistance and no deformation during sea or land transportation.

- To prevent moisture erosion during sea transportation, the product is wrapped in multi-layer moisture-proof packaging ( PE film + anti-rust paper + bubble pad), combined with desiccant and vacuum technology to ensure that it will not oxidize or discolor during transportation.

- The end protection uses high-density foam plugs or customized plastic caps to prevent the end from bumping or deformation during transportation, and is suitable for projects with precise installation requirements.

- For long beams, segmented packaging or pallet loading is supported to facilitate unloading and on-site lifting by customers, and lifting marks and lifting point prompts can be provided.

- Each batch of products is equipped with Chinese and English identification labels, packing lists, MTC material reports and customer-specified information labels to facilitate customer warehousing, traceability and project reconciliation.

- For special projects, we can provide customized packaging solutions such as IPPC fumigation marks, pallet codes, European/American standard certified wooden boxes, etc. to meet the compliance requirements of exports to the EU, America, the Middle East and other regions .

Related product recommendations

If your project requires other structural profiles, we can also provide them:

FAQ

What is the minimum order quantity?

We offer a minimum order quantity of 1 for standard stock sizes, facilitating sample testing and small-batch projects. For custom sizes or special alloys, the minimum order quantity is typically 100–200 kg, depending on the model and processing technique.

Can you provide free samples?

We offer small-size or cut-out samples , with shipping costs borne by the customer. For custom or surface-treated samples, please contact our sales team to confirm your needs.

How is the price of titanium I-beam calculated?

Pricing is primarily determined by factors such as material grade, cross-sectional dimensions, length, machining availability, surface treatment, and order quantity. Since titanium is a high-value metal, market prices fluctuate significantly. We recommend contacting us for a real-time quote.

How to calculate the theoretical weight of a titanium I-beam?

The following formula can be used to estimate the weight (using an I-shaped symmetrical beam as an example):

kg/m² = titanium density × [2 × flange width × thickness + web height × thickness]. The density of titanium is generally 4.51 g/cm³. If calculation is inconvenient for you, please send us a drawing and we will provide a detailed weight and quote within 2 hours.

Can titanium I-beams be customized?

We support personalized services such as extrusion mold opening, CNC machining, drilling, end processing, welding, surface polishing or sandblasting to adapt to customers' specific project drawings.

Do you support export and provide the necessary documents for customs clearance?

We can provide invoices, packing lists, certificates of origin (CO), material reports (EN 10204 3.1), SGS third-party testing, MSDS, ROHS/REACH declarations, etc. along with the goods to meet the customs clearance requirements of different countries and regions.

What is the typical lead time for titanium I-beams?

In-stock specifications are typically shipped within 3–5 business days. Custom specifications are subject to process complexity and typically have a lead time of 10–20 days.

Spot inventory details list

| Section height H (inch / mm) | Flange width B (mm) | Web thickness tw (mm) | Flange thickness tf (mm) | Standard length (m) | Spot materials |

|---|---|---|---|---|---|

| 3″ (≈76) | 76 | 3 / 4 / 6 / 8 | 5 / 6 / 8 / 10 | 3 / 6 | Gr2 / Gr5 |

| 4″ (≈100) | 100 | 5 / 6 / 8 / 10 / 12 | 6 / 8 / 10 / 12 / 15 | 3 / 6 | Gr2 / Gr5 |

| 5″ (≈125) | 75 | 5 / 8 / 10 / 12 / 15 | 6 / 8 / 10 / 12 / 15 | 3 / 6 | Gr2 / Gr5 |

| 6″ (≈150) | 100 | 6 / 8 / 10 / 12 / 15 / 20 | 8 / 10 / 12 / 15 / 20 | 3 / 6 | Gr2 / Gr5 |

| 6″ (≈152) | 152 | 8 / 10 / 12 / 15 / 20 / 25 | 10 / 12 / 15 / 20 / 25 | 3 / 6 | Gr2 / Gr5 |

| 7″ (≈178) | 102 | 8 / 10 / 12 / 15 / 20 / 25 | 10 / 12 / 15 / 20 / 25 | 3 / 6 | Gr2 / Gr5 |

| 8″ (≈200) | 100 | 10 / 12 / 15 / 20 / 25 / 30 | 10 / 12 / 15 / 20 / 25 | 3 / 6 | Gr2 / Gr5 |

| 8″ (≈203) | 152 | 10 / 12 / 15 / 20 / 25 / 30 / 40 | 12 / 15 / 20 / 25 / 30 | 3 / 6 | Gr2 / Gr5 |

| 10″ (≈250) | 125 | 12 / 15 / 20 / 25 / 30 / 35 / 40 | 12 / 15 / 20 / 25 / 30 / 35 | 3 / 6 | Gr2 / Gr5 |

| 10″ (≈254) | 203 | 12 / 15 / 20 / 25 / 30 / 40 / 50 / 60 | 15 / 20 / 25 / 30 / 35 / 40 | 3 / 6 | Gr2 / Gr5 |

| 12″ (≈300) | 150 | 15 / 20 / 25 / 30 / 40 / 50 / 60 / 70 | 18 / 20 / 25 / 30 / 35 / 40 / 45 | 3 / 6 | Gr2 / Gr5 |

| 12.31″ (≈312) | 203 | 20 / 25 / 30 / 40 / 50 / 60 / 70 / 80 / 100 / 120 | 20 / 25 / 30 / 35 / 40 / 45 / 50 / 60 / 70 | 3 / 6 | Gr2 / Gr5 |

illustrate:

- The table above lists the specifications of Titanium I-beams that Chalco Titanium always has in stock .

- Dimensions not included in the table can be customized according to customer needs, supporting special cross-sectional design, different wall thickness and length processing.

- We provide cut-to-length, surface treatment and logistics support services to ensure that the application scenarios of different engineering projects are met.