Titanium T Section

Today, high strength, lightweight, and corrosion resistance are key design factors. Titanium T Profiles (T-section Extrusions) are widely used in high-end manufacturing fields such as aerospace, marine engineering, chemical equipment, and medical devices due to their unique "T" cross-sectional structure and excellent performance.

Whether you're looking for an aerospace-grade T-section for reinforcement or a corrosion-resistant structural profile to replace stainless steel, we can provide you with high-quality, traceable titanium T-bar solutions—from material selection and processing to packaging and shipping, with full delivery guarantee.

Popular alloy types available from Chalco Titanium

As a professional supplier with ISO 9001 / AS9100 quality system certification, Chalco offers various grades of titanium alloy T-sections to meet your applications in different projects.

-

Grade 1 Titanium T-Sections are known for their excellent ductility and corrosion resistance. They are suitable for applications where structural loads are small but good weldability and chemical resistance are required, such as chemical supports or lightweight frames.

-

Grade 2 Titanium T-Sections are widely used in industry, offering strength and corrosion resistance. They suit medium-load structures like offshore pipeline supports and equipment frames in acidic or alkaline environments.

-

Grade 5 Titanium T-Profiles are ideal for high-strength applications. With tensile strength up to 895 MPa, they handle heavier loads with smaller cross-sections and are used in aviation stiffeners, mechanical frames, and high-performance structures requiring both strength and lightness.

In addition to standard Grade 1, Grade 2, and Grade 5, we can also customize t-profiles in other titanium alloys, such as Grade 7, Grade 9, and Grade 23 (ELI), to meet specific environmental requirements for strength, corrosion resistance, or biocompatibility. Please provide us with drawings or application scenarios, and we will recommend the most suitable alloy and processing technology.

Popular stock sizes

Chalco Titanium maintains a wide variety of titanium T-profiles in stock year-round, covering popular sizes ranging from 20×20×2 mm to 80×80×8 mm. Suitable for a variety of structural applications, including aviation reinforcements, marine supports, and mechanical frames, we offer standard lengths of 3 and 6 meters, and we also offer cut-to-length services for immediate customer use.

All stock profiles are made of Grade 2 or Grade 5 alloy, ensuring consistent strength and dimensional accuracy. Whether you're looking for prototypes or large-volume shipments, Chalco Titanium ensures fast delivery, ensuring your project progresses efficiently.

For detailed stock specifications and available lengths , please click on the Titanium T-Seals stock chart for complete information.

Why choose titanium t profiles ?

-

Titanium's natural oxide film has excellent self-healing properties and can provide long-term corrosion protection even in high-salt, high-humidity, and high-chloride ion marine environments. Its corrosion resistance far exceeds that of stainless steel and aluminum alloys, making it suitable for structural components exposed to seawater or chemical media for a long time.

-

The T-section design enhances load distribution, transfers stress more evenly to the connection, and improves the structural stability of welded or bolted joints, making it particularly suitable for working conditions with vibration and dynamic loads.

-

Grade 5 titanium alloy has an extremely high strength-to-weight ratio. While maintaining the same load-bearing capacity, the overall structure can be reduced by 30–45%, helping customers optimize design weight and improve system efficiency. It is particularly suitable for fields with strict lightweight requirements, such as aviation, offshore engineering, and automated equipment.

-

Titanium T-profiles produced using hot extrusion and straightening processes have consistent cross-sectional dimensions, regular angles, and high surface finish, ensuring precise fit and minimal error during subsequent assembly, which can significantly reduce on-site finishing time and processing costs.

-

The surface is free of cracks and inclusions, and combined with the low elastic modulus of titanium, it can significantly reduce stress concentration, enhance fatigue resistance, extend life under alternating loads or long-term operation, reduce maintenance frequency, and make long-term use more cost-effective.

Adapt to multiple industries to create high-performance structural solutions

Aerospace structural reinforcement

At the connection points of the wing spars, fuel tank frames and composite skins, titanium T-profiles can be used as lightweight reinforcements to enhance the overall structural strength while effectively reducing weight to meet stringent flight load requirements.

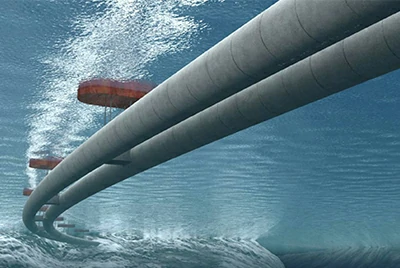

Deep-sea oil and gas and underwater engineering systems

Titanium T-profiles have excellent resistance to chloride ion corrosion and are widely used in pressure-bearing structures such as deep-sea pipeline supports, underwater equipment frames, and cable protection troughs, maintaining long-term stability and fatigue resistance.

Chemical and pharmaceutical equipment supports

In corrosive environments such as acid, alkali, and chlorine, titanium alloy T-profiles are used for reactor support frames, filter device frames, and fluid channel structures to prevent equipment deformation or leakage due to corrosion.

Energy sector (tidal /wind energy) structural parts

Used in hydroelectric power stations, underwater power blade bases, wind power equipment frames, etc., the T-shaped structure provides good vibration resistance and fatigue resistance, and can adapt to long-term load impact.

Medical and Electronic Devices Framework

Non-magnetic, corrosion-resistant titanium T-profiles can be used in CT, MRI, and medical instrument brackets to avoid magnetic interference and ensure measurement accuracy and equipment stability.

High-end automation and precision equipment framework

In the fields of semiconductor equipment, unmanned systems, optoelectronic systems, etc., titanium T-profiles are used as assembly skeletons to ensure structural accuracy while meeting the strict requirements for pollution-free and fatigue-resistant materials.

One-stop value-added services to help projects land efficiently

To meet customers' customized needs in different application scenarios, Chalco Titanium provides full-process supporting services from blank supply to finished delivery, ensuring that each batch of titanium T-profiles has higher assembly efficiency and delivery integrity.

Secondary processing services

We offer cutting, chamfering, drilling, slotting, face milling, and weld pretreatment services to meet the requirements of applications such as slide-in assembly, modular welding, and structural docking. Our machining accuracy is controlled within ±0.2 mm.

Surface treatment options

Conventional surfaces include mill finish, pickled, fine polishing (Ra ≤ 0.8 µm), and anodizing (black/blue/gold/color, etc.) to meet functional and appearance requirements.

Quality testing and certification

Ultrasonic testing (UT), eddy current testing (ET), dimensional testing, and spectral analysis are all available before shipment, along with an EN 10204 3.1 material report. We support ISO 9001, AS9100, PED, CE, and other certification requirements.

Export packaging services

We use multiple packaging methods, including pearl cotton, moisture-proof film, anti-collision pads, and fumigated wooden boxes, making it suitable for both air and sea transport. Each shipment is affixed with alloy markings, size labels, and anti-misloading identification codes to ensure safety and traceability during international transportation.

If you have special packaging, precision or testing requirements, please indicate them before placing an order and our engineering and quality teams will tailor a solution for you.

FAQ

Are samples provided free of charge?

We support the provision of small samples ≤ 200 mm for trial installation or testing. We only charge the courier fee. Please apply before placing an order.

What is the minimum order quantity?

The minimum order quantity for in-stock sizes is 25 kg, while custom sizes or special alloys require a minimum order quantity of 100 kg. Small trial orders are also available.

How to calculate the price of titanium T profiles?

titanium T-shaped profiles varies depending on factors such as the selected alloy grade (e.g., Grade 2 or Grade 5), dimensions, surface treatment, and the need for secondary processing. We recommend providing drawings or specific requirements. We will provide an accurate, real-time quote based on current raw material prices and inventory. Please contact us by email or using the "Quick Quote" form.

How to calculate the theoretical weight of titanium T profiles?

The formula is: cross-sectional area × length × density (4.51 g/cm³) . If you don't have the necessary calculation conditions, we can also provide a complete PDF calculation sheet or use a tool.

What is the usual delivery time?

Standard stock sizes can be shipped within 3–5 days. Custom products require approximately 7 days for mold creation, 3–5 days for extrusion and post-processing, and a total delivery time of approximately 10–12 working days.

Does it support processing or pre-processing according to drawings?

Yes. We can provide secondary processing such as cutting to length, slotting, drilling, chamfering, and end surface treatment according to customer drawings, with a tolerance within ±0.2 mm.

Related product recommendations

If your project requires other structural profiles, we can also provide them:

Stock size list

| Web Height (mm) | Flange Width (mm) | Web Thickness (mm) | Flange Thickness (mm) | Standard Length (m) |

|---|---|---|---|---|

| 20 | 20 | 3 | 3 | 3.0 / 6.0 |

| 25 | 25 | 3.5 | 3.5 | 3.0 / 6.0 |

| 30 | 30 | 4 | 4 | 3.0 / 6.0 |

| 35 | 35 | 4 | 4 | 3.0 / 6.0 |

| 40 | 40 | 5 | 5 | 3.0 / 6.0 |

| 45 | 45 | 5 | 5 | 3.0 / 6.0 |

| 50 | 50 | 6 | 6 | 3.0 / 6.0 |

| 55 | 55 | 6 | 6 | 3.0 / 6.0 |

| 60 | 60 | 6 | 6 | 3.0 / 6.0 |

| 65 | 65 | 7 | 7 | 3.0 / 6.0 |

| 70 | 70 | 7 | 7 | 3.0 / 6.0 |

| 75 | 75 | 8 | 8 | 3.0 / 6.0 |

| 80 | 80 | 8 | 8 | 3.0 / 6.0 |

illustrate:

-

All stock profiles support cut-to-length cutting.

-

Available alloys: Grade 2 (commercially pure titanium), Grade 5 (Ti-6Al-4V).

-

If the required specifications are not found in the table, we can provide customized mold opening and processing services.

Titanium t profiles tolerances

As a professional supplier of titanium alloy profiles, Chalco Titanium strictly adheres to the SAE AMS 2245C-2021 standard and comprehensively controls the key geometric tolerances of titanium T-profiles in terms of size, angle, flatness, straightness, twist, etc., to ensure that each batch of products meets the stringent requirements of aviation-grade structural parts for precision and consistency.

Transverse flatness tolerance (applicable to T-flanges)

| Surface Width (inches) | Tolerance (± inches) |

|---|---|

| Less than 1,000 | 0.01 |

| ≥1.000 | 0.010 × width |

| Within every 1 inch | Not to exceed 0.010 (local control) |

Twist tolerance

| Measuring section | Tolerance (°) |

|---|---|

| Every 1 foot or less | 1° |

| Whole profile | 1° per foot, but not exceeding 3° |

Surface defect depth tolerance

| T-Section Wall Thickness (inches) | Maximum allowable defect depth (inches) |

|---|---|

| ≤ 0.250 | 0.008 |

| 0.250 – 0.500 | 0.01 |

| > 0.500 | 0.015 |