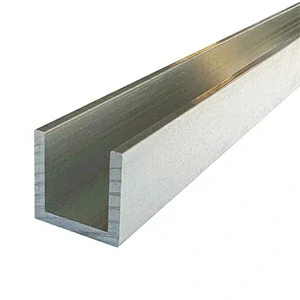

Titanium U Channel

Titanium u-channels, also known as titanium u-sections or titanium structural channels, are U-shaped profiles typically manufactured by extrusion or hot rolling. Combining high rigidity with lightweight properties, they are widely used in applications requiring high corrosion resistance and lightweighting, such as shipbuilding, aerospace supports, chemical equipment frames, and architectural curtain wall structures.

Certifications of Chalco can provide

To ensure the stable performance and global compliance of titanium U-channels in various high-standard projects , Chalco always adheres to the international quality system as the core, strictly controlling the entire process from raw materials and manufacturing to factory inspection. All products are traceable and provide complete third-party testing documents.

We can provide the following certifications based on customer project requirements:

- ISO 9001: Comprehensive quality management system covering the entire production process

- AS9100: a quality system specifically designed for the aerospace industry, applicable to aircraft and aerospace components

- IATF 16949: automotive industry quality standard, supporting new energy vehicles and rail transit applications

- PED (Pressure Equipment Directive): EU Pressure Equipment Directive, applicable to the export of chemical and pressure-bearing structure projects

such as EN 10204 3.1 material certificates, SGS/TÜV/BV third-party inspection reports, certificates of origin, and RoHS/REACH declarations of compliance, can be provided with the product. We also support project audit documentation and long-term supply arrangements. Please contact us to request certification samples and delivery lists.

Popular alloy types

Chalco can supply U-shaped channels in a variety of titanium alloy grades, including industrial pure titanium, α-β alloys and special purpose alloys, to meet the structural needs of multiple fields such as marine, aviation, chemical, and construction. The following are several types of titanium alloys we recommend and their typical applications in titanium U-shaped channel products:

-

Grade 2 Titanium U Channel titanium u-shaped channels are widely used for their excellent seawater corrosion resistance, good cold-workability, and high ductility. They suit structures like offshore platforms, water treatment frames, and condenser supports, resisting chloride corrosion and extending service life.

-

Grade 5 Titanium U Channel titanium is widely used in aerospace for its high strength, fatigue resistance, and light weight. Grade 5 U-shaped channels are ideal for aircraft load-bearing structures, UAV slide rails, and high-speed vehicle frames, offering rigidity, crack resistance, and high-temperature performance.

-

Grade 7 Titanium U Channel titanium u-shaped troughs, with palladium content, resist chloride and acidic corrosion. They are ideal for pickling tank supports, chemical tower frames, and pipe racks, offering greater durability than Grade 2 for chemical industry applications.

-

Grade 12 Titanium U Channel titanium u-channels offer excellent weldability, heat resistance, and galvanic corrosion protection. They are ideal for heat exchangers, exhaust pipe brackets, and pressure vessel frames, especially in electrochemically sensitive or high-temperature, humid environments.

-

Grade 23 Titanium U Channel titanium u-channels, the ELI version of Grade 5, offer higher toughness and biocompatibility. They are ideal for medical device brackets, laboratory instruments, and MRI-compatible structures where both strength and purity are crucial.

Select suggestion:

Different application environments have different requirements for the alloy performance of titanium u-shaped channels. The following are recommended selection suggestions based on the usage scenarios to help you match project needs more efficiently .

- For use in seawater or humid environments, it is recommended to choose Gr2, which is both corrosion-resistant and economical.

- There are high requirements for structural strength and lightness. It is recommended to choose Gr5, which is suitable for aviation or load-bearing occasions.

- For long-term contact with acid, alkali or chemical media, it is recommended to choose Gr7, which has stronger resistance to crevice corrosion.

What are the advantages of titanium u-shaped groove?

- Strong corrosion resistance, can be exposed to seawater and chemical environment for a long time without anti-corrosion coating

- High strength-to-weight ratio Approximately 40% lighter than stainless steel and still capable of carrying high loads

- Non-magnetic and non-sparking, can be used in electronic equipment and flammable and explosive environments

- Good high temperature resistance Grade 5 maintains high strength up to 400°C

- Long service life and almost maintenance-free, significantly reducing the total life cycle cost

Solutions and practical cases in different industries

Shipbuilding and offshore engineering

Titanium U-shaped channels are often used in floating platform railings, deck frames and desalination equipment brackets, and remain stable and reliable even under long-term exposure to high salt spray environments.

Case: A domestic offshore wind power platform uses Grade 2 titanium U-shaped channels to replace stainless steel brackets, with no corrosion record in 5 years and reduced maintenance costs by approximately 30%.

Aerospace

Titanium U-shaped grooves are widely used in aircraft cabin guide rails, satellite cabin frames and UAV frames, taking into account high strength, weight reduction and fatigue resistance.

Case: A European aviation parts manufacturer purchased Grade 5 titanium U-channels for use in lightweight seat structures. The materials are 18% lighter than aluminum alloys and have passed fatigue tests exceeding 20,000 cycles.

Chemical equipment

In the support structure of chlor-alkali tanks and pickling equipment, titanium U- shaped grooves can withstand high corrosion, high temperature and intermittent impact conditions, far exceeding traditional stainless steel.

Case: A large-scale desalination plant in Mexico replaced its 316L stainless steel structure with Grade 7 titanium U-channels. After 36 months, there was no sign of corrosion, and annual paint maintenance was completely eliminated, resulting in cumulative savings of over US$120,000 over three years.

Architectural decoration

Titanium U-shaped channels are used for coastal curtain wall keels, sunshade structures, etc. They have good weather resistance and decorative properties, and anodizing treatment can provide a variety of color options.

Case: A sea view hotel in Dubai, UAE uses titanium U-shaped grooves as the brackets for the facade sunshade device, which can resist wind, sand and salt spray erosion for more than 5 years and still maintain a smooth appearance.

Medical devices

Grade 23 ELI titanium U -shaped groove is commonly used in high-standard medical occasions such as MRI equipment frames and sterile room support structures due to its non-magnetic and high cleanliness.

Case: A German medical device manufacturer uses titanium U-shaped channels instead of stainless steel frames for X-ray imaging equipment to avoid magnetic interference and reduce the total weight of the equipment by 15%.

Multiple sizes available in stock

Chalco maintains a wide range of titanium U-shaped channels, covering belly heights from 20–100 mm, wing widths from 10–50 mm, and wall thicknesses from 2–6 mm, to meet the needs of various engineering structures. Standard lengths are 3 m and 6.0 m, and custom cuts are also available.

All stock profiles are precision extruded and straightened to exacting dimensional tolerances:

- Belly height /wing width tolerance ±0.5 mm

- Wall thickness tolerance ±0.3 mm

- Straightness ≤0.5 mm/m

- Smooth surface and flat edges, can be directly used for welding or mechanical connection

Regular specifications in stock can be shipped within 48-72 hours. We also support small-batch customization and mold opening services to help customers save time and improve installation efficiency.

To view detailed specifications, weight and available lengths, please click on the stock size details

How big is the performance gap between u-shaped grooves made of different materials?

U-shaped channels made of different materials vary significantly in terms of corrosion resistance, weight, strength, and lifespan. The following is a comparison of key performance indicators among titanium, stainless steel, and aluminum alloy:

| Comparison Item | Titanium U-shaped channel (Grade 2 / 5) | Stainless steel U-shaped channel (such as 304/316L) | Aluminum alloy U-shaped channel (such as 6061/6063) |

|---|---|---|---|

| Corrosion resistance | Extremely strong, resistant to seawater, acid and alkali, no coating required | Medium, prone to pitting corrosion at the seaside, requires regular maintenance | Generally, it is afraid of acid corrosion and needs anode or coating protection. |

| Density/weight | About 4.5 g/cm³, lighter than stainless steel | About 8.0 g/cm³, heaviest | About 2.7 g/cm³, the lightest but weakest |

| strength | High strength (especially Grade 5) to withstand heavy loads | Medium strength, commonly used in conventional structures | Low strength, easy to deform, limited load-bearing capacity |

| High temperature performance | 400°C still maintains more than 90% strength | High temperature resistant, but with significant thermal expansion and contraction | Strength drops rapidly at high temperatures and is easy to soften |

| Service life | Up to 10 years or more, basically maintenance-free | Regular inspection and rust removal are required | Easy to oxidize, requires regular maintenance |

| Cost and price/performance ratio | The initial cost is high, but the life cycle cost is low, which is more cost-effective in the long run | Medium cost, maintenance required later | Low cost but frequent maintenance and limited service life |

Titanium U-channels are an ideal choice for applications requiring extreme corrosion, high strength, or long life. They are particularly well-suited for demanding industries such as offshore, aviation, chemical, and medical. If you're undecided about your choice, we can provide detailed alternative recommendations and project- specific solutions. Please contact us for more technical information and samples.

Value-added services that Chalco Titanium can provide

Surface treatment

We offer a variety of surface treatments for titanium U-shaped channels, which can be flexibly selected according to the use environment and appearance requirements.

Conventional treatment includes pickling to remove the oxide layer and improve surface cleanliness;

Sandblasting to create a uniform matte texture, which helps subsequent coatings adhere;

Bright annealing treatment restores the material to its original color and luster, making it suitable for structural parts that require visual effects.

In addition, we can also perform anodizing treatment, and the surface color can be customized to blue, gold, rainbow colors, etc., which are widely used in architectural decoration and visible facade structures.

Precision machining

We have mature titanium secondary processing capabilities, including CNC, waterjet cutting, slot milling and other high-precision processes, which can realize complex structures such as U-shaped slots, grooving, drilling, end face chamfering, etc.

For titanium slotted U-channel structures, we can prefabricate interfaces or holes according to customer drawings to achieve integrated connection with titanium angle steel, C-channel and other profiles, greatly improving on-site installation efficiency and reducing engineering assembly costs.

Packaging

To ensure product safety during transportation, we use multi-layer protective packaging solutions.

Each titanium U-shaped trough is first wrapped individually with PE film, then the outer layer is covered with moisture-proof kraft paper and foam cushioning, and finally packed into a reinforced wooden box to ensure that the product is not damaged during long-distance transportation.

The packaging is suitable for various logistics modes such as sea transportation, air transportation and railway transportation to meet the delivery needs of customers in different regions.

Quality inspection and factory information

All products shipped are accompanied by complete quality documentation, including a commercial invoice, packing list, certificate of origin, and EN 10204 3.1 material test report. For additional customer requirements, we can arrange third-party testing such as SGS and TÜV. We also support customized labeling, inkjet printing, and packaging coding to meet project review and traceability needs.

Stock size details

| Abdominal height H (mm) | Wing width B (mm) | Wall thickness T (mm) | Standard length (m) |

|---|---|---|---|

| 20 | 10 | 2 | 3.0 / 6.0 |

| 20 | 15 | 2.5 | 3.0 / 6.0 |

| 20 | 20 | 3 | 3.0 / 6.0 |

| 25 | 15 | 2.5 | 3.0 / 6.0 |

| 25 | 20 | 3 | 3.0 / 6.0 |

| 30 | 20 | 3 | 3.0 / 6.0 |

| 30 | 25 | 4 | 3.0 / 6.0 |

| 30 | 30 | 4 | 3.0 / 6.0 |

| 40 | 20 | 3 | 3.0 / 6.0 |

| 40 | 25 | 4 | 3.0 / 6.0 |

| 40 | 30 | 4 | 3.0 / 6.0 |

| 40 | 40 | 5 | 3.0 / 6.0 |

| 50 | 25 | 4 | 3.0 / 6.0 |

| 50 | 30 | 4 | 3.0 / 6.0 |

| 50 | 40 | 5 | 3.0 / 6.0 |

| 50 | 50 | 6 | 3.0 / 6.0 |

| 60 | 30 | 4 | 3.0 / 6.0 |

| 60 | 40 | 5 | 3.0 / 6.0 |

| 60 | 50 | 6 | 3.0 / 6.0 |

| 70 | 30 | 4 | 3.0 / 6.0 |

| 70 | 40 | 5 | 3.0 / 6.0 |

| 70 | 50 | 6 | 3.0 / 6.0 |

| 80 | 40 | 5 | 3.0 / 6.0 |

| 80 | 50 | 6 | 3.0 / 6.0 |

| 90 | 40 | 5 | 3.0 / 6.0 |

| 90 | 50 | 6 | 3.0 / 6.0 |

| 100 | 40 | 5 | 3.0 / 6.0 |

| 100 | 50 | 6 | 3.0 / 6.0 |

The above stock specifications are available in Grade 2, Grade 5, and Grade 7 titanium alloys. If you can't find the right size or alloy, please contact us. We can provide custom cutting services to meet your engineering needs.

Related product recommendations

If your project requires other structural profiles, we can also provide them:

FAQ

What factors affect the price of titanium U-shaped groove?

The price of titanium U-channels is affected by factors such as titanium raw material market conditions, alloy grade, cross-sectional dimensions, processing method, and order quantity. Please provide your specifications and purchasing requirements, and we will provide you with a quote and recommend the most cost-effective option.

What is the minimum order quantity?

Stock sizes support a minimum order quantity of 25 kg, making them suitable for proofing or small- batch projects . Custom sizes or non-standard specifications typically have a minimum order quantity of 500 kg, which can be flexibly negotiated based on the model and processing difficulty.

Can you provide free samples?

We can provide small samples (e.g., 100–200mm) for testing or evaluation purposes for engineering projects or long-term clients. Some standard sizes can be provided free of charge, with shipping at the client's expense or upon delivery. Please contact us to inquire about available sample sizes and arrangements.

Can titanium u-channels be welded to stainless steel parts?

Yes, but a dissimilar metal welding process is required. It is recommended to use titanium welding wire, argon protection and control heat input to avoid the formation of brittle intermetallic compounds and ensure structural strength and weld reliability.

Is grooving supported?

secondary processing such as precision grooving, drilling, and chamfering on titanium U-shaped slots within 6 meters . The slot size tolerance can be controlled within ±0.2 mm.

How to calculate the weight of non-standard size U-channel?

You can use the following calculation formula to quickly estimate the theoretical weight, or you can send us a drawing and we will provide a complete PDF weight calculation sheet within 2 hours.

Weight calculation formula:

kg / m = ρ × [2 × wing width × t + ( belly height − 2t) × t] ÷ 1 000 000

in:

- ρ: density ( 4510 kg/m³ for Grade 2)

- Wing width: The width of the left and right sides of the U-shaped groove (unit: mm)

- Belly height: the total height of the middle vertical part (unit: mm)

- t: wall thickness (assuming equal thickness on three sides, unit: mm)