3D Titanium Wire

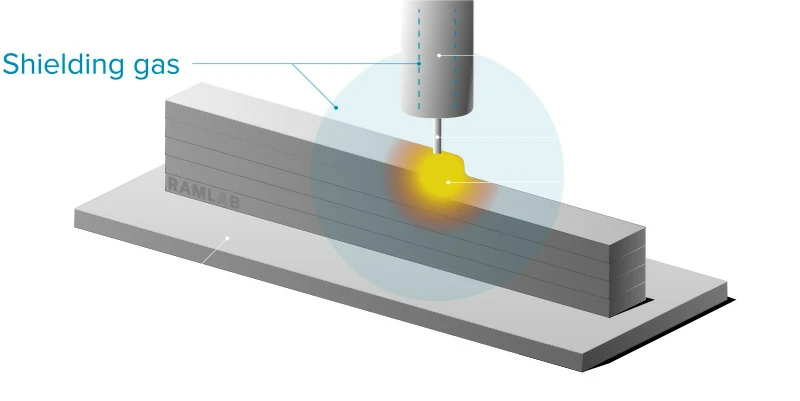

3D Titanium Wire is a high-performance feedstock engineered for wire-based Additive Manufacturing processes such as WAAM (Wire Arc Additive Manufacturing) and DED (Directed Energy Deposition). Unlike conventional titanium welding wire, it is designed for structural applications, delivering an exceptional strength-to-weight ratio, excellent corrosion resistance, and stable inter-layer fusion. It is widely used in aerospace, medical implants, and energy equipment where performance requirements are stringent.

As a titanium manufacturer, Chalco Titanium supplies titanium wire for 3D printing in 0.8–3.2 mm diameters across Gr1, Gr2, Ti-6Al-4V, ELI, and Ti5553 alloys, conforming to ASTM B863, F136, and ISO 13485. Through multiple melts, precision drawing, and vacuum annealing, we ensure high surface cleanliness, controlled gas content, and excellent print consistency—enabling efficient, reliable additive manufacturing.

Why Choose Titanium Wire for Additive Manufacturing?

In high-performance sectors such as aerospace, medical, and energy, titanium wire offers an ideal material solution for structural additive manufacturing due to its high strength-to-weight ratio, corrosion resistance, and excellent biocompatibility. Compared to conventional forging or powder-based methods, wire-based processes like WAAM and DED combined with titanium's intrinsic advantages can significantly reduce costs, boost efficiency, and support complex, near-net-shape printing. Key benefits include:

- High deposition rates of 2–4 kg/h with WAAM—50–100× faster than powder laser processes—ideal for large-scale components.

- Material-efficient deposition, applying titanium only where needed, saving 25–50% material compared to forging.

- Superior high-temperature strength, with alloys like Ti-6Al-4V retaining ~90% strength at 400°C—suitable for thermally loaded parts.

- Topology optimization and structural integration for lightweight, multifunctional designs.

- Compatible with multiple energy sources, including MIG/TIG arc, laser, and electron beam—supporting all mainstream wire AM systems.

- Non-magnetic, non-toxic, and biocompatible—ideal for implants, life sciences, and high-end industrial applications.

- Lower overall production cost, shorter lead times, and stable printing quality compared to traditional machining or forging routes.

Need guidance on alloy or diameter selection for your specific application?

Specifications of Titanium Wire for Additive Manufacturing

Chalco Titanium supplies premium titanium wire for additive manufacturing, tailored to meet the requirements of WAAM, DED, EBAM, and other wire-based deposition methods. We support customization of wire diameter, spool size, annealing state, and surface cleanliness, ensuring compatibility with a wide range of printing systems in aerospace, medical, energy, and research industries.

| Available Grades | Applicable Processes | Wire Diameter Range | Tolerance | Surface Conditions | Spool Weight | Packaging | Standards |

|---|---|---|---|---|---|---|---|

| Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr23 (Ti-6Al-4V ELI), Ti5553, Ti6242 | WAAM, DED, EBAM, LMD, Laser Wire, Plasma | 0.8 mm – 3.2 mm (Standard: 1.2 / 1.6 / 2.0 / 2.4 / 3.175 mm) | ≤1.6 mm: ±0.025 mm; >1.6 mm: ±0.05 mm; custom tolerances available | Vacuum annealed, acid-cleaned, polished, oil-free cleaned | 10 – 200 kg, depending on wire diameter and spool size | Vacuum sealed, plastic spool, desiccant and dustproof protection | ASTM B863, ASTM F136, ASTM F67, ISO 5832-3, ISO 13485, EN 10204 3.1 / 3.2, JIS H4670 |

For large-diameter wires (≥3.0 mm), high-capacity spooling is available to reduce feeding interruptions and improve overall deposition efficiency.

Need a custom size or detailed technical drawing?

Recommended Titanium Alloys for Additive Manufacturing

Choosing the right titanium alloy is critical to ensuring print quality, especially when considering the mechanical requirements and service conditions of the printed part. Chalco Titanium offers a full range of titanium wire for additive manufacturing, covering aerospace, medical, and industrial sectors. The table below provides recommended alloy selections compatible with WAAM, DED, EBAM, and other mainstream wire-fed AM processes:

| Alloy Grade | Recommended Process | Application Scenarios | Selection Highlights |

|---|---|---|---|

| Gr1 / Gr2 | WAAM / DED / LMD | Medical tools, marine parts, light-load structures | Excellent formability, corrosion resistance, and cost-effectiveness |

| Gr5 (Ti-6Al-4V) | WAAM / DED / EBAM | Aerospace components, energy equipment, industrial parts | High strength with good printability; the most commonly used titanium alloy |

| Gr23 (Ti-6Al-4V ELI) | WAAM / LMD | Medical implants, orthopedic scaffolds | Extra low interstitials, excellent biocompatibility, ideal for implant-grade uses |

| Ti5553 / Ti6242 | EBAM / WAAM | Aircraft frameworks, high-temperature load-bearing parts | High strength and heat resistance for demanding structural applications |

| Gr7 (Ti-0.2Pd) | WAAM (limited usage) | Chemical equipment, corrosion-resistant components | Exceptional corrosion resistance but higher cost; rarely used in AM |

| Gr9 (Ti-3Al-2.5V) | WAAM / LMD (occasional use) | Lightweight parts, bicycles, sports equipment | Medium strength between Gr2 and Gr5; suitable for printing light-duty components |

Not sure which alloy fits your machine and application?

---Industry Solutions & Application Scenarios

Aerospace|Optimal Solution for Lightweight Complex Structures

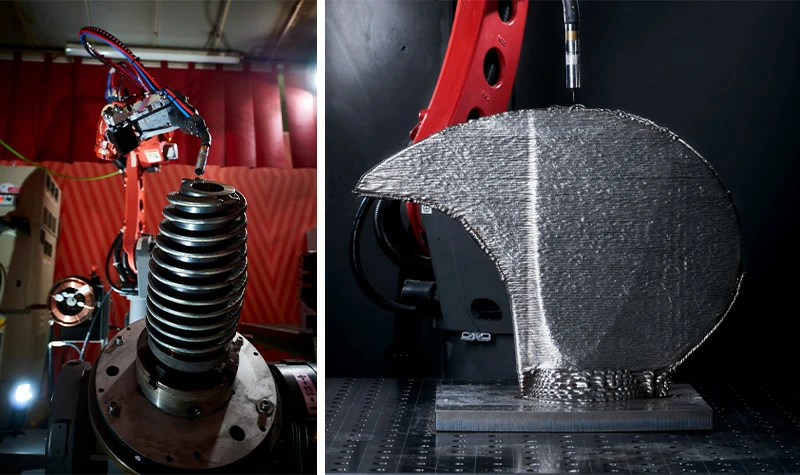

Aerospace components often feature complex shapes, thin walls, and intricate load paths. Traditional forging and machining result in high buy-to-fly ratios and long lead times, making it difficult to balance lightweight performance with structural integrity. Additive manufacturing using titanium wire (e.g., Ti-6Al-4V) enables topology-optimized and near-net-shape printing, improving material utilization and reducing delivery time.

Typical Applications: Landing gear structures, nozzle rings, wing stiffeners, satellite brackets

Real-World Cases:

WAAM3D partnered with an aerospace OEM to produce an Aft Pylon Bracket Mount for the Airbus A320 using Ti-6Al-4V titanium wire and WAAM technology. The printed part replaced a forged component, significantly reducing weight while accommodating complex geometries.

WAAM3D printed a landing gear rib using Ti-6Al-4V wire, achieving a 60% material saving. The part was completed in just 27 hours and successfully passed multiple performance tests.

Norsk Titanium supplies 3D printed titanium structural parts for the Boeing 787 Dreamliner via WAAM, saving up to $2 million per aircraft, with over $100 million saved annually.

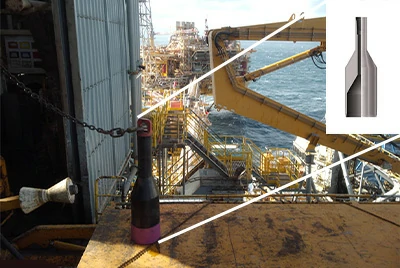

Energy & Marine|Ideal for Large Corrosion-Resistant Structures

Offshore platforms and nuclear systems demand components that can endure extreme environments, such as high salinity and elevated temperatures. Traditional methods struggle with long cycles and high costs. WAAM with Gr7 (Ti-0.2Pd) titanium wire enables the near-net-shape fabrication of large corrosion-resistant parts with fewer joints.

Typical Applications: Heat exchanger tube sheets, support brackets, corrosion-resistant shells, transmission covers

Real-World Case:

In collaboration with Thales Alenia Space, WAAM3D printed a 1-meter-high titanium tank using Ti-6Al-4V wire. Results included 80% material savings, 40% cost reduction, and 65% shorter lead time.

Medical|High-Purity, Customized Implant Solutions

Medical devices—especially implants—demand high purity, biocompatibility, and dimensional precision. Additive manufacturing using Gr23 (Ti-6Al-4V ELI) titanium wire is ideal for personalized orthopedic implants and surgical scaffolds.

Typical Applications: Acetabular cups, spinal connectors, cranio-maxillofacial supports, custom surgical templates

Real-World Case:

Osseus Fusion Systems in the USA used 3D printed titanium wire to create patient-specific spinal implants from Ti-6Al-4V ELI, achieving FDA approval. The implants have been successfully used in multiple clinical spinal surgeries, significantly improving patient fit and recovery outcomes.

Find more medical titanium wire products→

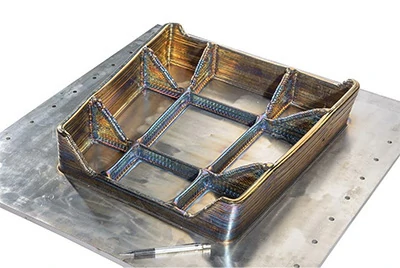

Industrial Manufacturing & Repair|Smart, Cost-Effective Remanufacturing

Industrial parts such as molds, housings, and brackets often suffer localized wear or corrosion during service. Traditional repair methods are time-consuming and costly. WAAM combined with titanium wire allows for efficient component repair or additive remanufacturing, minimizing downtime and extending service life.

Typical Applications: Engine housings, mold repair layers, equipment support frames, mining liners

Manufacturing Process & Quality Control

Dedicated Production Process for Additive Manufacturing

Chalco Titanium adopts a specialized production process tailored for titanium wire used in additive manufacturing, with all steps—from melting to final packaging—completed on independent production lines. This ensures uniform alloy microstructure, stable mechanical properties, and smooth wire feeding. Unlike conventional welding wire, our titanium wire is engineered for high deposition efficiency and consistent formability, ideal for WAAM, DED, EBAM, and other demanding applications.

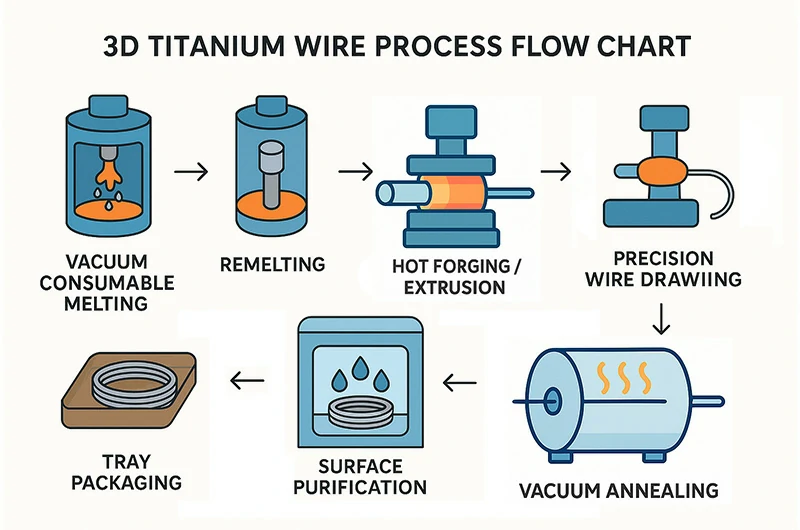

Main Manufacturing Steps:

→ Vacuum consumable electrode melting→ Remelting→ Hot forging / extrusion→ Precision wire drawing→ Vacuum annealing→ Surface purification→ Spooling & packaging

Key Advantages:

- Fully controlled in-house process, with batch-level traceability

- Precision control of wire diameter and ovality, ensuring compatibility with high-speed feeding systems

- Multiple heat treatments to adjust mechanical states

- Dedicated AM wire lines to prevent process mixing with welding wire

Quality Inspection & Traceability System

We have established a comprehensive testing system covering chemical composition, microstructure, mechanical performance, and surface quality. Each batch is supplied with an EN 10204 3.1 / 3.2 certificate and supports full lot traceability and third-party inspection.

- O/N/C/H gas content and grain size analysis

- Tensile strength, surface roughness, and cleanliness

- Non-destructive testing (eddy current / ultrasonic)

- Wire feeding simulation on spool to verify print stability

Surface Finish & Cleanliness Control

Surface cleanliness is critical to additive manufacturing quality. Our wires undergo specialized low-temperature degreasing, acid pickling, polishing, and dust-free drying, combined with manual light inspection and HD imaging systems to eliminate impurities, discoloration, or surface defects.

- Ra ≤ 0.8 μm, free from oil, oxide scale, or contamination

- No joints, dents, or cracks that could compromise print quality

- Customizable surface options: pickled / polished / bright finish

*Surface roughness Ra indicates the average microscopic height variation (μm) on the wire surface.

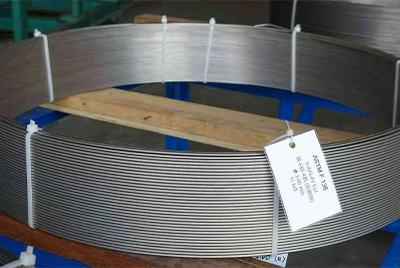

Packaging & Logistics

To ensure cleanliness and safety during transport and storage, Chalco Titanium provides dedicated packaging solutions tailored to additive manufacturing titanium wire. Each spool is vacuum-sealed or inert-gas protected immediately after winding, followed by moisture-proof PE wrap, shock-absorbing foam, and reinforced plywood crates—effectively preventing contamination and damage. Maximum single spool weight up to 200 kg, supporting long continuous print jobs.

All products carry unique labels with clear details: material, batch number, wire diameter, tolerance, production date, and recommended print parameters. Full traceability and documentation are available, including:

- EN 10204 3.1 / 3.2 material certificates

- Full-process Certificate of Analysis (COA)

- Heat number and traceability records

Chalco Titanium is certified under ISO 9001, ISO 13485, AS9100, and EN 9100 quality management systems. All packaging materials comply with international shipping and environmental regulations, supporting global delivery and customs clearance.

FAQs

-

What's the difference between 3D printing titanium wire and traditional welding wire?

What's the difference between 3D printing titanium wire and traditional welding wire?

Although both are titanium-based, titanium wire for additive manufacturing requires higher standards in chemical uniformity, feeding stability, cleanliness, and ovality control. It typically undergoes dedicated surface purification and vacuum annealing to ensure proper layer bonding during printing. It is not recommended to use welding wire for AM.

-

Which titanium alloys are commonly used in additive manufacturing?

Which titanium alloys are commonly used in additive manufacturing?

The most widely used are Ti-6Al-4V (Gr5) for industrial applications and Ti-6Al-4V ELI (Gr23) for medical use. Gr2 and Gr1 are ideal for applications requiring high ductility or purity, while Gr7 and Gr9 are suited for corrosion-resistant components in energy and marine sectors.

-

Do you support medical-grade alloy certifications (e.g., F136 / ISO 13485)?

Do you support medical-grade alloy certifications (e.g., F136 / ISO 13485)?

Yes. Chalco Titanium supplies Gr23 (ELI) titanium wire in compliance with ASTM F136, and is certified to ISO 13485 medical quality standards—meeting the requirements for orthopedic implants and surgical applications.

-

Which additive manufacturing processes are compatible with your wire?

Which additive manufacturing processes are compatible with your wire?

Our titanium wire supports major wire-based AM technologies including WAAM (Wire Arc Additive Manufacturing), DED (Directed Energy Deposition), and EBAM (Electron Beam AM). It is already applied in aerospace, energy, and medical sectors.

-

Can wire diameter, tolerance, and surface finish be customized?

Can wire diameter, tolerance, and surface finish be customized?

Yes. We offer standard diameters from 1.2 mm to 6.35 mm, with tolerances down to ±0.02 mm. Surface options include pickled, polished, and bright finish, and we can also customize annealing conditions and low-oxygen levels per your process needs.

-

How do you ensure consistency and traceability during printing?

How do you ensure consistency and traceability during printing?

Each batch comes with EN 10204 3.1 / 3.2 certificates and a unique heat number for full traceability. Mechanical performance and print parameter feedback are recorded to ensure stable and repeatable printing results.

-

How is cleanliness and safety maintained during packaging and delivery?

How is cleanliness and safety maintained during packaging and delivery?

All titanium wire is packaged in vacuum-sealed or inert-gas environments, followed by moisture-proof bags, shock-absorbing foam, and plywood or carton boxes to prevent contamination and physical damage. Spools up to 200 kg are available for continuous AM production and export.

-

Do you offer samples or support small-batch trial runs?

Do you offer samples or support small-batch trial runs?

Yes. We provide samples or pilot batches and can recommend the appropriate alloy and condition based on your printing system and parameters—helping you validate and optimize your process quickly.

Get a Tailored Titanium Wire Solution for Additive Manufacturing

Chalco Titanium offers high-performance titanium wire optimized for WAAM, DED, EBAM, and other AM methods. We support custom alloy selection, wire dimensions, and surface treatments, and provide full material certification and parameter recommendations.

Contact us today for technical consultation and a competitive quote.