Gr1 Titanium Wire for Corrosion Resistance and Formability

As the representative of commercial pure titanium (CP Titanium), Grade 1 Titanium Wire is renowned for its excellent corrosion resistance, outstanding formability, and low density. It is the preferred choice for industries such as chemical processing, marine engineering, medical applications, and pressure vessel manufacturing. Not only does it maintain stability in chloride and acidic environments, but it also offers exceptional cold working properties and weldability.

Chalco Titanium offers Grade 1 Titanium Wire that meets the standards of ASTM B863 / ASTM F67, available for fast delivery from stock, accompanied by EN 10204-3.1 material certificates and SGS testing, ensuring compliance with stringent industry certifications.

Specifications of Gr1 Titanium Wire

| Alloy | Gr1 / Grade 1 Titanium Wire / UNS R50250 |

|---|---|

| Wire Diameter | Ø0.10 mm – 6.00 mm (Custom up to Ø10 mm) |

| Tolerance | Ø≤0.50 mm:±0.01 mm 0.50 <Ø≤ 1.50 mm:±0.02 mm Ø>1.50 mm:±0.03 mm |

| Condition | Annealed / Cold-Drawn |

| Surface | Bright / Pickled / Polished |

| Coil / Supply Form | D100 / D200 / D300 Coil Straight bars (≤ 3 m) |

| Standards | ASTM B863 / ASTM F67 / AWS A5.16 (ERTi-1) |

Technical Specifications & Industry Standards

Chemical Composition (ASTM B863)

| Element | Content (Weight %) |

|---|---|

| Oxygen (O) | ≤ 0.18 |

| Nitrogen (N) | ≤ 0.03 |

| Carbon (C) | ≤ 0.08 |

| Hydrogen (H) | ≤ 0.015 |

| Iron (Fe) | ≤ 0.20 |

| Titanium (Ti) | Balance (Remaining) |

Tensile Strength (Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength (UTS) | ≥ 240 MPa (35 ksi) |

| Yield Strength (YS - 0.2% Offset) | ≥ 170 MPa (25 ksi) |

| Elongation | ≥ 24% |

| Modulus of Elasticity | 103 GPa |

Standards Applied

- ASTM B863 — Titanium and Titanium Alloy Wire Standard

- ASTM F67 / ISO 5832-2 — Medical Pure Titanium Wire Standard

- AWS A5.16 ERTi-1 — Welding Wire Standard

- EN 10204-3.1 — Material Certificate (Available upon request)

Note: Gr1 Titanium Wire, due to its high ductility, is ideal for deep drawing, explosive cladding, cold forming, as well as TIG/MIG welding applications.

Need a full performance report or standard comparison? Click below to get the datasheet or contact an engineer to confirm your application compatibility.

Advantages of Grade 1 Titanium Wire

- 1.Optimal Ductility: Gr1 is the softest grade among commercial pure titanium, offering exceptional plasticity. It is ideal for deep drawing, cold forming, and explosive cladding processes.

- 2.Outstanding Corrosion Resistance: Performance in chloride, seawater, and most chemical media far exceeds that of stainless steel, reducing equipment corrosion and maintenance costs.

- 3.Lightweight Properties: With a density of only 4.51 g/cm³, it is approximately 40% lighter than steel, which helps reduce structural weight and improve energy efficiency.

- 4.Medical-Grade Safety: Compliant with ASTM F67 and ISO 5832-2 standards, offering excellent biocompatibility, suitable for medical implants and cleanliness requirements.

- 5.Excellent Weldability: Meets AWS A5.16 (ERTi-1) specifications, supporting TIG/MIG welding, producing dense, corrosion-resistant welds.

Typical Applications of Grade 1 Titanium Wire

Explosion Cladding

Spec: Ø 1.5–2.0 mm

Explosion welding requires filler materials with high toughness and ductility to absorb impact energy and prevent interface cracking. Gr1 Titanium Wire is the standard material for titanium-steel composite plate manufacturing, ensuring strong interface bonding and preventing delamination.

Spec: Ø 0.10–0.50 mm

Gr1 offers the best ductility and can be cold drawn into ultra-fine wire, with high weaving efficiency and resistance to breakage. It is widely used for weaving electrolysis electrode meshes, filters, and separation device meshes, suitable for chlor-alkali, electrolytic cells, desalination, and fuel cell systems.

Spec: Ø 0.25–0.60 mm

Gr1 Titanium Wire meets ASTM F67 and ISO 5832-2 standards, offering excellent biocompatibility. It is commonly used for surgical fixation wires, guide wires, and minimally invasive medical instruments. The wire undergoes ultrasonic cleaning and vacuum packaging to meet medical-grade cleanliness requirements.

Precision Springs & Cold-Formed Parts

Spec: Ø 0.3–1.2 mm

The exceptional ductility of Gr1 makes it suitable for manufacturing micro springs and cold-formed components, avoiding processing cracks and enhancing fatigue life. It is widely applied in electronics and medical devices.

Chemical & High-Corrosion Environments

Spec: Ø 1.0–1.6 mm

In chloride, acidic, and seawater environments, Gr1 Titanium Wire outperforms stainless steel in corrosion resistance, making it ideal for chemical binding wires, cathode hangers, and catalyst supports. It ensures long-term operation and reduces downtime and maintenance costs.

Not sure which specification is best for your project? Click below to get a professional selection and pricing solution.

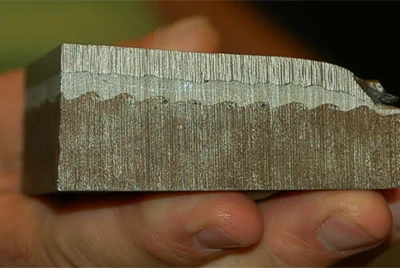

Manufacturing Process & Deep Processing

Manufacturing Process

Chalco Titanium Wire production follows a fully traceable process control to ensure consistent chemical composition, dimensional tolerance, and stable performance. The process includes: Vacuum Melting → Secondary Remelting → Hot Forging / Extrusion → Multiple Cold Drawing Passes (Bright Drawing) → Vacuum Annealing → Surface Purification → Coiling / Cut to Length

- Purity Guarantee: VIM + VAR double vacuum melting ensures O/H/Fe levels are controlled to 20% below standard limits

- Precision Control: PLC-controlled drawing equipment, with tolerances controllable to ±0.01 mm

- Cleanliness Process: Vacuum annealing + triple purification (Pickling → Ultrasonic Cleaning → Argon Drying), with surface oxide layer ≤ 0.3 μm

For Gr1 Titanium Wire, the annealed condition is more prevalent, ensuring excellent ductility to meet the requirements for explosive cladding, medical applications, and titanium wire mesh weaving.

Deep Processing & Delivery Capability

Delivery Assurance: Standard specifications can be delivered within 4-6 weeks, with samples available in as little as 2 weeks.

Flexible Customization: Supports various wire diameters, coil specifications, and surface treatments to meet diverse application needs such as aerospace, medical, and additive manufacturing.

Deep Processing Services:

- Cut to Length (tolerance ±0.5 mm)

- End Chamfering / Precision Grinding to improve assembly efficiency

- Mirror Polishing (Ra ≤ 0.2 µm)

- Medical-Grade Ultrasonic Cleaning (Particle residue < 25 µm)

- Third-Party Testing: SGS / BV certification included with shipments

Chalco Titanium Advantages as a Supplier

Quality & Certification in One Go

ISO 9001 + AS9100D dual system certifications, accompanied by EN 10204-3.1 material certificates and barcode traceability. SGS/BV third-party reports available with shipments, ensuring traceability and reliable quality for every coil of titanium wire.

Stock & Small Batch, Predictable Delivery

Standard specifications from 0.10 – 6 mm are available in long-term stock, with a minimum order quantity of 1 kg and samples shipped within 2 weeks. We support DDP/DAP door-to-door logistics, ensuring no production line downtime due to material shortages for urgent projects.

Product Range & Alloy Availability

Chalco supplies a full range of titanium wire grades to meet different strength and corrosion-resistance requirements, including commercially pure Grade 2 titanium wire, high-strength alloy Grade 5 titanium wire, and medical-grade Grade 23 titanium wire. These materials are widely used in industrial, aerospace, and biomedical applications.

24/7 Engineering Support

Dedicated engineers are available around the clock to assist with AWG-mm conversions, welding parameters, product selection comparisons, and other technical issues, reducing communication and trial-and-error costs.

Need certification documents or real-time inventory? Click below to request a quote, and Chalco Titanium will provide a solution within the same day.

Grade 1 vs Grade 2 Titanium Wire

| Comparison Item | Gr1 Titanium Wire (Grade 1) | Gr2 Titanium Wire (Grade 2) |

|---|---|---|

| Tensile Strength | ≥ 240 MPa | ≥ 345 MPa |

| Elongation | ≥ 24% | ≥ 20% |

| Corrosion Resistance | Excellent (Ideal for chemical and seawater desalination applications) | Good (Suitable for a balance of strength and corrosion resistance) |

| Density | 4.51 g/cm³ | 4.51 g/cm³ |

| Formability | Best ductility, easy deep drawing and ultra-fine wire drawing | Good formability, higher strength |

| Welding Performance | Meets AWS A5.16 ERTi-1 | Meets AWS A5.16 ERTi-2 |

| Cost | Lower | Slightly higher |

| Typical Applications | Explosion cladding, titanium wire mesh, medical implants, fine springs | Pressure vessels, heat exchanger binding wires, structural components |

Gr1 Titanium Wire is known for its excellent ductility and corrosion resistance, making it ideal for explosive cladding, medical implants, and fine wire weaving.

Gr2 Titanium Wire offers a balance of strength and corrosion resistance, making it more suitable for heat exchanger binding wires and structural components.

Material Selection Key Points:

- Corrosion resistance + Cold working: Choose Gr1

- Strength + Structural components: Choose Gr2

Not sure which to choose? Click below for an application comparison analysis and pricing solution.

FAQ

What are the typical applications for Gr1 Titanium Wire? Is it better than Gr2?

If your application prioritizes corrosion resistance and formability (such as medical, explosive cladding, titanium wire mesh), Gr1 is more suitable and cost-effective. If you require a balance of corrosion resistance and higher strength (such as pressure vessels, heat exchanger binding wires), choose Gr2.

What surface finishes are available for Gr1 Titanium Wire? Does it support medical-grade cleanliness?

Chalco Titanium offers Bright, Pickled, and Polished surface finishes, and can perform medical-grade ultrasonic cleaning, with particle residue < 25 μm, meeting implant and high cleanliness requirements.

What is the smallest diameter for Gr1 Titanium Wire? What precision applications is it suitable for?

It can be cold drawn to 0.10 mm while maintaining excellent ductility, making it ideal for micro springs, medical guide wires, and precision weaving. We offer tolerances of ±0.01 mm, ensuring machining accuracy.

Is Gr1 Titanium Wire suitable for weaving titanium wire mesh?

Yes, Gr1 offers the best ductility and can be cold drawn into ultra-fine wires down to 0.10 mm. It is widely used for electrolysis electrode meshes, filters, and separation devices, commonly applied in chlor-alkali, electrolytic, and seawater desalination systems. Chalco provides uniform wires and precise tolerances to ensure weaving performance.

Can Gr1 Titanium Wire be used for explosion cladding? Why is it more suitable than Gr2?

Yes, Gr1 has the highest ductility and toughness, enabling it to absorb impact energy during explosion welding, preventing interface cracking. It is commonly used for composite plate welding. In contrast, Gr2, with higher strength but lower ductility, is not suitable for this process.

Do you support small batch orders and customization? What is the delivery lead time?

Yes, Chalco supports small batch orders starting from 1 kg. Standard Ø0.10–6 mm specifications are available in long-term stock, with samples delivered within 2 weeks and bulk orders within 4–6 weeks. We also support DDP/DAP international logistics.