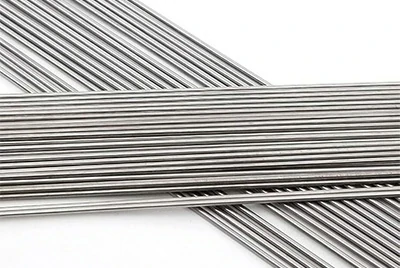

ERTi-2 Titanium Welding Wire

In critical welding applications such as chemical equipment, heat exchange systems, and seawater environments, ERTi-2 Titanium Welding Wire (Titanium Grade 2 Welding Wire) stands out as a cost-effective alternative to stainless steel and nickel-based welding wires, thanks to its ≥99.5% titanium purity, excellent ductility, and resistance to chloride corrosion.

Chalco offers a fully integrated production line (melting—drawing—annealing) to ensure that each batch of product meets AWS A5.16 standards, with a shortest delivery time of 2 weeks, fully supporting customer welding process verification and bulk supply requirements.

ERTi-2 Quick Selection: Specifications and Packaging Options

| Item | ERTi-2 Filler Rod | ERTi-2 Welding Wire |

|---|---|---|

| Welding process | TIG welding (Gas Tungsten Arc Welding) | MIG welding (automatic wire feeding) |

| Diameter range | Ø 1.0 / 1.6 / 2.0 / 2.4 / 3.2 mm | Ø 0.8 / 1.0 / 1.2 / 1.6 / 2.0 mm |

| Length | 36 inches (914 mm) standard | 5 – 15 kg per spool, continuous feed |

| Packing | Plastic tube / box (1-5 kg / tube) | Vacuum plastic bag + carton / wooden box |

| Surface condition | Bright annealed | Deoxidized, clean, dry anti-oil treatment |

| Applicable Scenarios | Precision welds, process samples, small batch welding | Automated welding, long welds, industrial batch welding |

| Optional Services | Cut-to-length / Private label / Small packaging distribution | OEM private label / Special spool types / Pre-set feed heads |

Whether you need a single sample or bulk delivery, Chalco can provide compliant materials, fast delivery, and flexible packaging support.

Product categories

ERTi-2 Titanium TIG Rod

Ideal for manual TIG welding, it ensures a small heat-affected zone and smooth formation, making it perfect for precise components and high-cleanliness welding processes.

Contact us now

ERTi-2 Titanium MIG Wire

Ideal for automated MIG welding (Gas Metal Arc Welding), it is suited for high-volume titanium structure welding and long welds.

Contact us nowWhether you need a single sample or a whole batch of supplies, Chalco can provide compliant materials, fast delivery and flexible packaging support. We also provide customized services, including cut-to-length, private label, OEM, etc., to meet the personalized needs of different customers.

ERTi-2 Technical Parameters and Standards

The ERTi-2 Titanium Welding Wire provided by Chalco complies with the following international welding and material standards:

- AWS A5.16 – Certification standard for titanium and titanium alloy filler metals used in welding

- UNS R50120 – Designation corresponding to ERTi-2

- AMS 4951 – Aerospace industry specification for titanium welding wires

ERTi-2 titanium welding wire is primarily manufactured in accordance with AWS A5.16, which differs from ASTM B863 (industrial titanium wire standard), as filler wire must meet specific welding performance requirements.

Chemical Composition

| Element | Ti | Fe | O | C | N | H |

|---|---|---|---|---|---|---|

| Content Range | ≥99.5% | ≤0.30% | ≤0.25% | ≤0.08% | ≤0.03% | ≤0.015% |

*Low impurity control enhances corrosion resistance and weld joint toughness.

Mechanical Properties

| Property | Tensile Strength | Elongation (A5) | Elongation (A5) | Density | Modulus of Elasticity |

|---|---|---|---|---|---|

| Value | ≥345 MPa | ≥275 MPa | ≥20% | 4.51g/cm³ | 105GPa |

*Excellent ductility ensures weld zones are not prone to cracking, making it suitable for applications with high heat-affected zone control requirements.

GTAW (Gas Tungsten Arc Welding) Recommended Parameters

| Diameter (inch / mm) | Welding Process | Voltage (V) | Current (A) | Shielding Gas |

|---|---|---|---|---|

| 1/16" (1.6 mm) | GTAW (TIG) | 16 V | 180 A | 100% Argon |

| 3/32" (2.4 mm) | GTAW (TIG) | 17 V | 190 A | 100% Argon |

| 1/8" (3.2 mm) | GTAW (TIG) | 19 V | 205 A | 100% Argon |

*Recommended shielding gas: ≥99.99% purity argon. Welding current and voltage may vary depending on joint type, base metal thickness, and heat input control.

Chalco ensures that all titanium welding wires undergo spectral composition analysis, tensile performance testing, and surface cleanliness testing before shipment to guarantee welding stability and batch consistency.

Why Choose ERTi-2?

- Outstanding Corrosion Resistance: Stable performance in seawater, chloride ions, nitric acid, and organic media environments

- Excellent Ductility: A5 ≥20%, good weldability, smooth formation

- Non-magnetic / Non-toxic: Suitable for high-purity applications in medical, food, and aerospace industries

- Good Thermal and Electrical Conductivity: Facilitates controlled heat transfer during welding, reducing the risk of heat cracks

- Easy to Weld: No preheating required, compatible with TIG, MIG, plasma welding, and other processes

Titanium Welding Wire Applications: ERTi-2 Titanium Welding Wire, Essential for Engineering Welding

Chemical Equipment

In environments with corrosive media such as chlorides and nitric acid, ERTi-2 welding wire combined with high-purity argon gas ensures weld seam density and corrosion resistance.

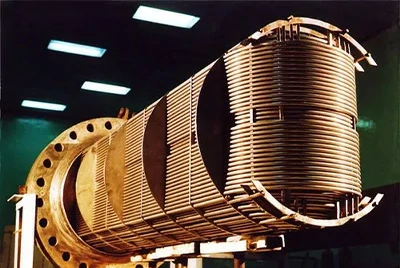

Typical Applications: Titanium storage tanks, titanium towers, titanium heat exchanger shells

Seawater Desalination

Facing high salt and chloride corrosion, ERTi-2 welding wire effectively prevents heat cracks, making it suitable for high-strength welding of seawater condensers and offshore platform pipelines.

Typical Applications: Seawater condenser pipelines, titanium seawater desalination heat exchangers, offshore platform pipelines

Medical Equipment

The low-oxygen and low-nitrogen, non-polluting welding process makes ERTi-2 the preferred choice for medical and implant welding, meeting the ISO 10993 biocompatibility requirements.

Typical Applications: Medical devices, implants, precision mechanical component welding

Aerospace/Nuclear Power

In high-temperature, high-pressure environments, ERTi-2 welding wire provides reliable joint strength and stability, widely used in aerospace components and nuclear power heat exchangers.

Typical Applications: Engine pipelines, nuclear power heat exchangers, energy equipment vacuum pipelines

Having understood the primary characteristics of the welding wire, let's now compare different welding wire models and their performance advantages.

Welding Wire Selection Comparison

Pure Titanium Series (ERTi-1/2/3/4) Performance Ladder

| Grade | Chemical Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Applications |

|---|---|---|---|---|---|

| ERTi-1 | Ti ≥ 99.5% | 275 MPa (min) | 170 MPa (min) | ≥ 25% | Medical, Food Processing |

| ERTi-2 | Ti ≥ 99.5% | 345 MPa (min) | 275 MPa (min) | ≥ 20% | Chemical, Seawater Desalination |

| ERTi-3 | Ti ≥ 99.0% | 380 MPa (min) | 280 MPa (min) | ≥ 15% | High-Temperature, Aerospace |

| ERTi-4 | Ti ≥ 99.0% | 480 MPa (min) | 380 MPa (min) | ≥ 15% | Aerospace, Heat Exchangers |

ERTi-2 vs. ERTi-5 Comparison Table

| Property | ERTi-2 | ERTi-5 |

|---|---|---|

| Chemical Composition | Ti ≥ 99.5% | Ti-6Al-4V (6% Al, 4% V) |

| Tensile Strength | 345 MPa (min) | 900 MPa (min) |

| Yield Strength | 275 MPa (min) | 800 MPa (min) |

| Elongation | ≥ 20% | ≥ 10% |

| Features | High corrosion resistance, stable welding performance | High strength, suitable for high-temperature environments |

| Applicable Base Metals | CP-Ti, Ti Gr1–Gr4 | Ti-6Al-4V, Titanium Alloys |

| Typical Applications | Chemical equipment, seawater desalination, medical | Aerospace, automotive, military, petrochemical |

ERTi-2 (pure titanium welding wire) is suitable for chemical equipment, seawater desalination, and medical fields. It offers excellent corrosion resistance and good weldability, making it ideal for use in industries with high cleanliness requirements.

ERTi-5 (titanium alloy welding wire, Ti-6Al-4V) provides exceptional tensile and yield strength, widely used in aerospace, automotive, military, and petrochemical applications, offering stable joint strength in high-temperature and highly corrosive environments.

Why Choose Chalco? Production Assurance + Service Advantages

Full Supply Chain Guarantee: Stable Quality, Flexible Delivery

- In-house Production: From melting to drawing, surface treatment, and deep processing, Chalco fully controls the production process to ensure product consistency and process reliability.

- Stock Inventory: Offering TIG / MIG welding wire in various specifications with ready stock to meet customer demands at any time.

- Product Coverage: We supply a complete range of titanium welding wire and titanium welding rod products for structural, corrosion-resistant, and industrial applications.

- Flexible Delivery: Standard delivery time is 4–6 weeks, with samples delivered within 2 weeks, supporting expedited production to ensure timely project progress.

International Certifications & Strict Quality Control

- Certification System: All welding wire products are certified under ISO 9001 and AS9100 quality management systems, ensuring that every batch meets international standards.

- Quality Testing: Every batch undergoes strict testing, including chemical composition analysis, tensile testing, and surface cleanliness checks to ensure welding pass rate.

- Third-Party Certification: SGS, BV, and other third-party certifications are available, ensuring compliance with EN 10204 3.1 standards and traceability.

Custom Services + Technical Support

- Customization Options: Offering cut-to-length rods, spooled wires, private label, and small packaging distribution services according to customer needs, meeting various project requirements.

- Material Grades Available: Including commercially pure titanium such as Grade 1 titanium wire and high-strength alloys such as Grade 5 titanium wire, suitable for different welding environments and performance requirements.

- Technical Support: Chalco provides comprehensive welding technical support, with engineers offering guidance on process parameters and welding evaluation assistance.

- Sample Support: Free samples available for welding trials to ensure compatibility with customer welding processes.

Chalco provides comprehensive supply chain guarantees, flexible customization services, and international certifications to ensure that every batch of welding wire meets customer needs and is delivered on time. Whether it's the project initiation phase or bulk production, Chalco always collaborates with clients to ensure welding quality and process reliability.

Frequently Asked Questions (FAQs)

What are the welding gas requirements for ERTi-2 welding wire?

To ensure optimal performance during welding, it is recommended to use pure argon gas (Ar) with a flow rate of 10-15 L/min. Pure argon effectively prevents oxidation, ensuring clean welds and quality.

What welding methods are suitable for ERTi-2 welding wire?

ERTi-2 welding wire is widely used in TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding methods. With excellent welding performance, it is suitable for precision welding and large-scale automated welding, providing strong weld joints while effectively controlling the heat-affected zone to prevent cracking.

How does ERTi-2 welding wire compare to stainless steel welding wire?

Compared to stainless steel welding wire, ERTi-2 welding wire has superior corrosion resistance, especially in environments with chlorides, nitric acid, and other corrosive media. With a density of approximately 4.5 g/cm³, it is 40% lighter than stainless steel, reducing structural load, and contains no iron or impurities, making it more suitable for high-purity welding.

Which base materials is ERTi-2 welding wire compatible with?

ERTi-2 welding wire is particularly suitable for titanium and titanium alloy base materials such as CP-Ti (Grade 1, Grade 2) and titanium alloys. It is also compatible with welded joints involving titanium-stainless steel and titanium-aluminum alloys, providing good compatibility and mechanical performance.

How can welding defects be avoided during the process?

Ensure cleanliness: Clean the base material surface before welding to remove oil, oxide scale, and other contaminants. Control heat input: Maintain appropriate welding current and voltage to avoid overheating. Use appropriate shielding gas: Protect the welding area with pure argon (Ar) to prevent oxidation and contamination. Proper welding sequence and speed: Ensure uniform welds and avoid uneven heat effects that may cause cracking.

What is the delivery time for ERTi-2 welding wire?

The standard delivery time is 4–6 weeks. For urgent orders, we offer expedited production, with samples available within 2 weeks. Specific delivery times may vary based on order volume, specifications, and production schedules. Customers can confirm details with our sales team.

Chalco provides full technical support and quick response services to assist you with any issues related to titanium welding wire procurement and welding processes.