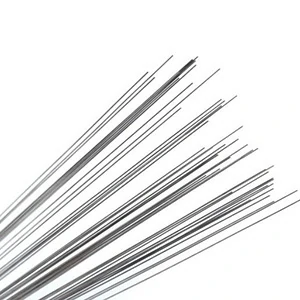

ERTi-5 Titanium Welding Wire (Ti-6Al-4V) is a high-performance titanium alloy filler material engineered for demanding applications such as aerospace, automotive manufacturing, and petrochemical industries. It delivers exceptional tensile strength, corrosion resistance, and heat resistance, making it ideal for welding in high-temperature and extreme environments.

Chalco operates a fully integrated production chain (melting – wire drawing – annealing – precision finishing), ensuring every batch strictly complies with AWS A5.16 and related standards. We guarantee fastest delivery in 2 weeks, supporting welding procedure qualification and bulk production needs.

ERTi-5 Titanium Welding Wire Specifications & Sizes

Specifications and Dimensions

| Item | ERTi-5 Filler Rod | ERTi-5 Spool Wire |

|---|---|---|

| Diameter Range | Ø1.0 / 1.6 / 2.0 / 2.4 / 3.2 mm | Ø0.8 / 1.0 / 1.2 / 1.6 mm |

| Length / Spool | 36 in (914 mm) standard | 5–15 kg per spool (D-100 / D-200 / D-300) |

| Packaging | Plastic tube / Carton (1–5 kg) | Vacuum-sealed bag + Carton / Wooden case |

| Welding Process | TIG (Gas Tungsten Arc Welding) | MIG (Gas Metal Arc Welding) |

| Surface Condition | Bright Annealed | Deoxidized, Clean & Dry |

| Standards | AWS A5.16, UNS R56400, AMS 4954, EN ISO 24034:STi6402/TiAl6V4B | |

| Welding Position | All positions (Flat, Horizontal, Vertical, Overhead) | |

Whether you need a single sample rod or bulk supply, Chalco offers fully compliant materials, rapid delivery, and flexible packaging solutions. We also provide customization services such as cut-to-length, private labeling, and OEM packaging to meet your project-specific requirements.

Product Categories

-

ERTi-5 Titanium TIG Rod

Designed for TIG welding, offering high welding precision, suitable for thin-walled titanium parts and clean welding environments.

-

ERTi-5 Titanium MIG Wire

Optimized for automated MIG welding, ideal for long seams and large-scale industrial production.

-

ERTi-5 Solid Welding Wire

Pure solid wire for high-quality and precision welding, compatible with TIG and MIG processes.

-

ERTi-5 Flux-Cored Welding Wire

Filled with flux for additional welding protection, recommended for highly corrosive or challenging welding environments.

ERTi-5 welding wire comes in multiple sizes and packaging options to fit different welding processes. Whether it's TIG or MIG welding, Chalco guarantees premium welding materials and tailored services to ensure your project runs smoothly.

Technical Specifications & Standards

Chalco's Ti-6Al-4V Welding Wire (ERTi-5) complies with the following international welding and material standards:

- ERTi-5 Titanium TIG Rod Designed for TIG welding, offering high welding precision, suitable for thin-walled titanium parts and clean welding environments.

- ERTi-5 Titanium MIG Wire Optimized for automated MIG welding, ideal for long seams and large-scale industrial production.

- ERTi-5 Solid Welding Wire Pure solid wire for high-quality and precision welding, compatible with TIG and MIG processes.

- ERTi-5 Flux-Cored Welding Wire Filled with flux for additional welding protection, recommended for highly corrosive or challenging welding environments.

ERTi-5 welding wire comes in multiple sizes and packaging options to fit different welding processes. Whether it's TIG or MIG welding, Chalco guarantees premium welding materials and tailored services to ensure your project runs smoothly.

Technical Specifications & Standards

Chalco's Ti-6Al-4V Welding Wire (ERTi-5) complies with the following international welding and material standards:

- AWS A5.16 – Specification for Titanium and Titanium-Alloy Welding Electrodes and Rods

- UNS R56400 – Designation corresponding to ERTi-5

- AMS 4954 – Aerospace industry standard for titanium alloy welding wire

Note: ERTi-5 welding wire strictly follows AWS A5.16, unlike ASTM B863 (industrial titanium wire standard), as welding wire must meet specific welding performance requirements.

Chemical Composition

| Element | Ti | Al | V | Fe | O | C | N | H |

|---|---|---|---|---|---|---|---|---|

| Content | Balance | 5.5–6.75% | 3.5–4.5% | ≤0.30% | ≤0.20% | ≤0.08% | ≤0.05% | ≤0.015% |

Mechanical Properties

| Property | Tensile Strength | Yield Strength | Elongation (A5) |

|---|---|---|---|

| Value Range | ≥900MPa | ≥830MPa | ≥10% |

GTAW (Gas Tungsten Arc Welding) Parameters

| Wire Diameter (mm) | Welding Current / Polarity | Voltage (V) | Amperage (A) | Shielding Gas | Welding Position | Notes |

|---|---|---|---|---|---|---|

| Ø1.6 | GTAW / DCEN (with EWTh-2 truncated cone electrode) | 9–12 | 100–180 | Argon | All positions | For precision welding, thin titanium parts |

| Ø2.4 | GTAW / DCEN (with EWTh-2 truncated cone electrode) | 11–15 | 150–250 | Argon | All positions | Medium-thickness workpieces |

| Ø3.2 | GTAW / DCEN (with EWTh-2 truncated cone electrode) | 11–15 | 200–375 | Argon | All positions | Thick titanium sections |

*All-position welding: Flat, Horizontal, Vertical, Overhead.

GMAW (Gas Metal Arc Welding) Parameters

| Wire Diameter (mm) | Welding Current / Polarity | Voltage (V) | Amperage (A) | Shielding Gas | Welding Position | Notes |

|---|---|---|---|---|---|---|

| Ø0.8 | GMAW / DCEP Short-Circuit | 16–20 | 100–195 | Argon or Ar+He | All positions | Suitable for thin titanium parts |

| Ø1.2 | GMAW / DCEP Short-Circuit | 18–27 | 165–285 | Argon or Ar+He | All positions | Standard titanium welding |

| Ø1.6 | GMAW / DCEP Short-Circuit | 31–35 | 250–360 | Argon or Ar+He | All positions | High-efficiency welding for thick titanium |

*All-position welding: Flat, Horizontal, Vertical, Overhead.

After reviewing the chemical composition, mechanical properties, and welding parameters of ERTi-5 Titanium Welding Wire, you may now be wondering about the specific advantages it offers. Let's explore why ERTi-5 stands out in demanding welding applications.

Why Choose ERTi-5 Titanium Welding Wire?

- Exceptional Corrosion Resistance: Performs reliably in seawater, chloride, nitric acid, and organic media, resisting harsh corrosive environments—ideal for petrochemical and marine industries.

- Superior Ductility: With elongation ≥ 20%, ensures excellent weld plasticity and clean bead appearance—perfect for aerospace precision welding.

- Non-Magnetic & Non-Toxic: Compliant with medical, food-grade, and aerospace hygiene standards, ensuring safety in high-purity applications.

- Excellent Thermal & Electrical Conductivity: Improves heat control during welding, reduces cracking risk, and guarantees joint stability under high-temperature conditions.

- Outstanding Weldability: No preheat required; compatible with TIG, MIG, and plasma welding, ensuring efficiency and weld quality.

Beyond these technical benefits, ERTi-5 Titanium Welding Wire delivers consistent performance across critical, high-demand environments, making it the preferred choice for advanced engineering sectors.

Typical Applications of ERTi-5 Titanium Welding Wire

Aerospace

Thanks to its high strength and excellent heat resistance, Ti-6Al-4V Welding Wire delivers a superior welding solution for aerospace components, ensuring long-term stability under extreme conditions.

Typical Applications: Aircraft components, engine parts, spacecraft structures.

Petrochemical Industry

ERTi-5 Titanium Welding Wire is widely used for welding in offshore platforms and chemical equipment, particularly in highly corrosive and high-temperature environments. It offers exceptional corrosion resistance and strength, significantly extending equipment service life.

Typical Applications: Offshore platforms, chemical reactors, heat exchangers.

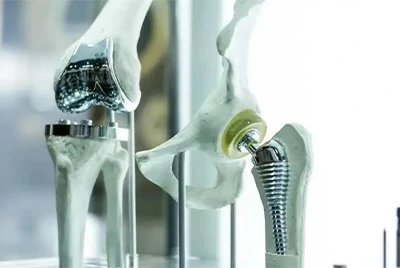

Medical Devices

Owing to its biocompatibility and non-toxic nature, ERTi-5 is extensively applied in the medical field, especially for manufacturing titanium alloy implants, ensuring joint integrity and durability.

Typical Applications: Titanium implants, surgical instruments, medical equipment.

Marine Engineering

In marine environments, the superior corrosion resistance of ERTi-5 makes it the ideal choice for welding deep-sea equipment and offshore structures, ensuring stability in salt spray and seawater conditions.

Typical Applications: Offshore platforms, deep-sea equipment, seawater cooling systems.

Automotive Manufacturing

With its lightweight and high-strength characteristics, ERTi-5 Titanium Welding Wire is highly preferred for welding high-strength automotive components, enhancing overall vehicle performance and durability.

Typical Applications: Engine parts, exhaust systems, lightweight body components.

ERTi-5 Titanium Welding Wire finds broad application in aerospace, petrochemical, medical, marine, and automotive industries. Its high strength, heat resistance, and corrosion resistance make it an ideal material for critical welding projects requiring superior performance and reliability.

ERTi-2 vs. ERTi-5 Titanium Welding Wire

| Item | ERTi-2 | ERTi-5 |

|---|---|---|

| Chemical Composition | Ti ≥ 99.5% | Ti-6Al-4V (6% Al, 4% V) |

| Tensile Strength | ≥ 345 MPa | ≥ 900 MPa |

| Yield Strength | ≥ 275 MPa | ≥ 830 MPa |

| Elongation | ≥ 20% | ≥ 10% |

| Features | Excellent corrosion resistance, stable weldability | High strength, suitable for high-temperature service |

| Base Materials | CP-Ti, Ti Gr1–Gr4 | Ti-6Al-4V and titanium alloys |

| Typical Applications | Chemical equipment, desalination, medical | Aerospace, automotive, defense, petrochemical |

ERTi-2 (Commercially Pure Titanium) welding wire is ideal for chemical processing, seawater desalination, and medical applications, providing excellent corrosion resistance and weldability in high-purity environments.

ERTi-5 (Titanium Alloy Ti-6Al-4V) offers superior tensile and yield strength, widely used in aerospace, automotive, defense, and petrochemical industries, delivering strong joints even under high-temperature and aggressive environments.

Want to know more?

- View ERTi-2 Titanium Welding Wire Details

- Explore Our Titanium Welding Wire Selection Guide

Next, choose a reliable partner to ensure consistent quality and on-time delivery.

Learn how Chalco's full production chain and strict quality standards secure your projects.

Why Choose Chalco: Production Capability & Service Advantage

Full Supply Chain Assurance: Consistent Quality, Flexible Delivery

- In-House Production Line: From melting, wire drawing, surface treatment to precision finishing, Chalco controls the entire process to ensure material consistency and process stability.

- Ready Stock: Covers multiple TIG and MIG specifications, enabling immediate supply for urgent needs.

- Product Coverage: We supply a complete range of titanium welding wire and titanium welding rod, supporting various industrial and structural welding applications.

- Flexible Delivery: Standard lead time 4–6 weeks, samples within 2 weeks, with expedited production available to keep your projects on schedule.

International Certifications & Strict Quality Control

- Certified Systems: All welding wires are produced under ISO 9001 and AS9100 quality management systems, guaranteeing compliance with international standards.

- Quality Testing: Every batch undergoes chemical composition analysis, tensile testing, and surface cleanliness inspection to ensure high weld integrity.

- Third-Party Verification: SGS, BV certifications available; products meet EN 10204 3.1 standards for full traceability.

Customization & Technical Support

- Custom Options: Available in rods, spooled wires, private labeling, and various packaging configurations to meet specific project requirements.

- Material Grades Available: Including commercially pure titanium such as Grade 1 titanium wire and Grade 2 titanium wire, suitable for corrosion-resistant and general industrial welding applications.

- Engineering Support: Our technical team provides welding parameter recommendations and assistance with welding procedure qualification (WPQ).

- Sample Support: Free samples available for trial welding to ensure process compatibility and welding performance.

Chalco delivers comprehensive supply chain assurance, flexible customization, and globally recognized certifications—ensuring every batch meets your quality standards and delivery timelines. Whether for initial trials or large-scale production, Chalco partners with you to guarantee welding reliability and process success.

FAQs

Which welding processes are suitable for ERTi-5 Titanium Welding Wire?

ERTi-5 wire is primarily used for TIG (Gas Tungsten Arc Welding) and MIG (Gas Metal Arc Welding). It is ideal for high-strength and corrosion-resistant welding applications in aerospace, petrochemical, and medical industries.

What is the maximum operating temperature for ERTi-5 wire?

ERTi-5 offers excellent heat resistance and can maintain welding integrity up to 400°C–500°C, depending on the material and application.

Which industries commonly use ERTi-5 Titanium Welding Wire?

It is widely used in aerospace, petrochemical, marine engineering, medical equipment, and automotive manufacturing, where high strength and corrosion resistance are critical. For enhanced corrosion resistance in chemical or seawater environments, you can choose ERTi-2 Titanium Welding Wire.

What precautions should I take when using ERTi-5 welding wire?

Maintain a clean welding environment to avoid contamination. Use high-purity argon or argon-helium mixtures for shielding gas. Ensure welding equipment settings match wire diameter and welding method.

What are the packaging and storage requirements for ERTi-5 wire?

Supplied in plastic tubes or cartons, typically 2–8 kg per unit. Store in a dry environment, avoiding moisture and oxidation to maintain optimal welding performance.

What is the delivery lead time?

Standard delivery is 4–6 weeks. For urgent requirements, sample orders can be shipped within 2 weeks. Exact timelines depend on order quantity and production schedule.

Chalco provides full technical support and rapid response services to address all your titanium welding wire procurement and welding process needs.