Titanium Bend Pipe

In high-temperature, high-pressure or strongly corrosive environments, standard piping components often fail to balance strength and service life. Titanium Bend Pipe offers exceptional corrosion resistance and lightweight structural advantages, making it widely used in chemical processing, marine systems, energy equipment and aerospace piping. It helps reduce overall equipment weight, extend service life, and maintain high accuracy and safety of fluid pipelines.

Chalco Titanium provides a fully integrated manufacturing process—from melting, extrusion, bending to inspection—and all products comply with ASTM B363 / ASTM B338 standards. We manufacture according to customer drawings with precise control of bending angles and radii, ensuring dimensional stability, weldability and efficient delivery, supplying engineering projects with reliable and cost-effective titanium alloy piping solutions.

Quick Selection Bar

Specification | Product Type | Alloy Grade

What Is a Titanium Bend Pipe?

A Titanium Bend Pipe is a high-precision titanium alloy pipe formed from seamless titanium tube through either cold bending or induction heating (hot bending process). Unlike standard elbows with fixed dimensions, titanium bend pipes can be fully customized according to project requirements — including bending angle, bend radius (R), and straight leg length (Leg Length) — making them suitable for complex piping layouts or installations within confined spaces.

Titanium bend pipes combine lightweight structure, high strength, and excellent corrosion resistance, and are widely used in heat exchanger systems, seawater cooling, chemical pipelines, and aerospace hydraulic lines. They offer higher flexibility and reliability in engineering design, and are considered an ideal upgrade to traditional stainless steel or copper-nickel pipe fittings.

What Are the Core Advantages of Titanium Bend Pipe?

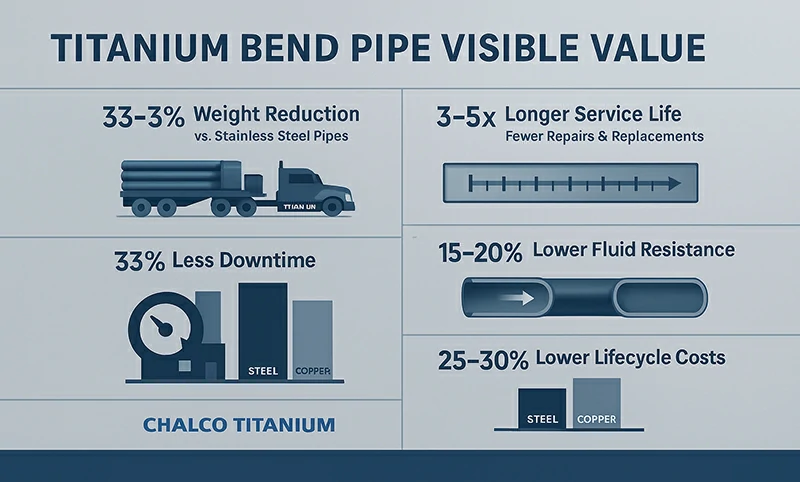

The value of Titanium Bend Pipe goes far beyond "corrosion resistance.” It enables engineering systems to operate in a lighter, more stable, and longer-lasting state, generating long-term returns from a single replacement.

With the same structural strength, a titanium bend pipe reduces overall weight by 30%–40% compared to stainless steel pipes, significantly lowering equipment load and transportation costs.

In chemical and seawater systems, its service life is 3–5 times longer than carbon steel, reducing maintenance shutdowns by up to twice per year.

In heat exchanger systems, its smooth, wrinkle-free inner surface improves fluid efficiency by 15%–20%, while maintaining stable pressure and flow rate.

Using CNC mandrel bending, the bending angle accuracy is controlled within ±0.5°, with minimal ovality and clean weld edges, allowing direct installation without secondary machining.

This means — customers are not only receiving a pipe fitting, but a complete solution that shortens construction time and reduces operational costs.

Chalco Titanium controls the entire process in-house—from titanium ingot to finished bend pipe. All raw tubes are sourced according to ASTM B338, and finished bend pipes are inspected and delivered per ASTM B363 and drawing requirements, accompanied by EN 10204 3.1 certification, ensuring more transparent and reliable engineering decisions.

Specifications (Angle & Dimensions)

We measure bending dimensions based on Center Line Radius (CLR), where R = OD × factor. The bending angle is measured from the centerline to ensure full consistency with engineering drawings.

- Outer Diameter (OD): 5–114.3 mm (¼″–4½″)

- Wall Thickness (WT): 0.5–15 mm (commonly 1–2 mm)

- Bend Radius (R): 1D / 1.5D / 2D / 3D / 5D / 10D / customized

- Bend Angle (θ): 15° / 30° / 45° / 60° / 90° / 135° / 180° (continuously adjustable)

- Leg Length (Straight Ends): 7″ / 9″ / customized (equal or unequal legs)

- Angle Accuracy: ±0.5°;Radius Tolerance: ±1% or ±0.5 mm (whichever is greater)

- Ovality: ≤8%;Wall Thinning: ≤10% (depending on OD / WT / R)

- End Forms: PE (Plain End) / BE (Beveled End 37.5°) / Cut-to-Length

- Delivery Condition: Pickled and clean, Ready-to-Weld

Information required for inquiry: OD × WT, R / CLR, angle, leg length, end type (PE / BE / cut), alloy grade, quantity, inspection requirements and delivery time.

Based on the above dimensional capabilities, we can customize multiple geometries according to drawings. Typical configurations are shown below.

Product Types

All examples below are available within the OD / WT / R / angle range specified on this page, fully customizable per drawings and supplied in Ready-to-Weld condition.

Titanium U Bend

Titanium J Bend

45° Titanium Bend

60° Titanium Bend

90° Titanium Bend

180° Titanium Bend

Piggable Titanium Bend

Small Radius Titanium Pipe

Thin-Wall Bend Titanium Pipe

Alloy Grades

We only use titanium tubes that comply with ASTM B338 as raw materials, and all bending and inspection are performed according to ASTM B363, with EN 10204 3.1 certificates provided upon delivery.

The following six grades are long-term, stable, engineering-validated options that can be quickly matched based on medium, temperature, and strength requirements.

-

Grade 1 (CP1) Titanium Bend Pipe Highest ductility, suitable for thin-wall tubes and small bending radii (Small Radius) with single-step forming. Used in lightweight exhaust systems, low-pressure fluid lines, compact installations with limited space. Offers high assembly efficiency and excellent deformation consistency. Selection Note: Best for "thin-wall + small radius + low pressure” applications; ideal when appearance and uniformity are required.

-

Grade 2 (CP2) Titanium Bend Pipe Balanced strength and formability; the most common choice for heat exchangers and seawater cooling systems. Widely used in U-bends, condensers, chemical corrosion-resistant pipelines, with good weldability and cost efficiency. Selection Note: Preferred for general media, ambient or moderate temperature, and projects requiring a balance of service life and cost.

-

Grade 5 (Ti-6Al-4V) Titanium Bend Pipe High strength-to-weight ratio, suitable for high-load and structural pressure lines, such as aerospace and defense hydraulic/fuel systems. Ensures strength while controlling weight—ideal for critical components. Selection Note: Small bend radius needs evaluation and is usually ≥2D; choose when strength and fatigue life are prioritized.

-

Grade 7 (Ti-Pd) Titanium Bend Pipe Titanium with added palladium, significantly improving resistance to acidic and chloride-rich environments. Suitable for chemical processing, seawater treatment, and long-term chlorine exposure systems. Selection Note: Preferred for highly corrosive or long-term chloride environments where durability and stability are key.

-

Grade 9 (Ti-3Al-2.5V) Titanium Bend Pipe High strength, easy to bend and weld, excellent thin-wall uniformity. Widely used in aerospace tubing, precision motion components, and weight-sensitive systems; stable performance in mandrel bending. Selection Note: Ideal for "thin-wall + high precision + reliability” bending needs; a balanced solution for small radius and high consistency.

-

Grade 12 (Ti-0.3Mo-0.8Ni) Titanium Bend Pipe Excellent corrosion resistance and weldability in warm chlorine and marine environments, with a wider temperature tolerance range. Applied in offshore engineering, thermal power plants, and power station cooling loops with continuous operation requirements. Selection Note: Preferred when the medium contains chlorine or elevated temperature, and long-term stable service is required.

Not sure which grade to choose? Send us your operating parameters, and we will provide material recommendations and minimum bending radius suggestions.

Applications & Use Cases

Chemical Processing & Seawater Treatment

In chloride-rich media with fluctuating acidity/alkalinity, standard fittings are prone to pitting and crevice corrosion. Using Titanium Bend Pipe (R = 2D–5D, U-bend commonly used) reduces overall system weight by 30%–40%, maintains low ovality at heat exchanger ends, extends service life to 3–5 times that of stainless steel, and reduces annual shutdowns by approximately 40%.

Common Grades: Grade 2 / Grade 7 / Grade 12

Energy · Power Generation · LNG

High temperature, high pressure, warm chlorides, and long operation cycles coexist in this sector. Induction bends (R = 2D–5D) are used for main pipeline systems, while small-radius mandrel bends are applied in branch lines. Maintenance intervals extend by 2–3 times, and total lifecycle cost is reduced by about 25%–30%.

Common Grades: Grade 2 / Grade 12

Aerospace

Hydraulic, fuel, and cooling loops require both lightweight construction and dimensional accuracy. Mandrel bending (1D–3D) with thin-wall control reduces system weight by about 40%, while ensuring high dimensional consistency.

Grade 5 is selected for critical load-bearing sections, while Grade 9 is typically used for general tubing harnesses.

Automotive & Motorsport

Exhaust and turbo piping systems require a smooth inner wall and stable curvature. Mandrel bending ensures wrinkle-free low ovality pipes, resulting in 15%–20% lower flow resistance, with improved acoustic and durability performance.

Common Grades: Grade 1 / Grade 2 / Grade 9

Medical Equipment

Applications require cleanliness, traceability, and controlled forming. Titanium bend pipes are delivered in Ready-to-Weld condition, with EN 10204 3.1 certificates and full NDT records, suitable for fluid transfer and structural support in medical systems.

Common Grades: Grade 2 (general use), Grade 5 may be considered depending on project requirements.

Manufacturing & Quality Control

Based on engineering drawings, the bending toolings are designed in accordance with Center Line Radius (CLR) and dimensional stack-up. Corresponding dies and mandrels are selected to match the design. After bending, the pipe undergoes cleaning, pickling, and end preparation, followed by NDT and leak testing to ensure it is delivered in Ready-to-Weld condition.

According to the OD/WT/R/bending angle capabilities on this page, we use the following two bending processes to match different operating conditions.

Mandrel Bending

Designed for thin-wall tubes and small-radius bends, using mandrels, clamp dies, pressure dies, and wiper dies to control metal flow, suppress wrinkling and ovality. Suitable for 1D–3D tight layouts and high consistency assemblies.

Typical control values: angle accuracy ±0.5°, radius tolerance ±1% or ±0.5 mm, ovality ≤8%, wall thinning ≤10%. These are typical targets and may be adjusted based on OD/WT/R and process route, subject to technical approval.

Hot Induction Bending

Used for thick-wall or large-diameter industrial pipelines, where a narrow band of the tube is induction-heated and then cooled in a controlled manner. This reduces springback and residual stress, enhances cross-section integrity, and is commonly applied in 2D–5D industrial and offshore pipelines.

Process features: low forming force, excellent section retention, ideal for subsequent welding and on-site installation.

Post-Bending Finishing

After bending, the tubes undergo ultrasonic cleaning and acid pickling. End configurations include Plain End (PE), Beveled End 37.5° (BE), or cut-to-length per drawing. Stress-relief treatment can be applied if required to ensure dimensional stability and weldability. All products are delivered clean and Ready-to-Weld, eliminating secondary processing and reducing installation downtime.

Testing & Release

Non-destructive testing and leak testing are carried out according to project requirements, including PT (Penetrant Testing), UT (Ultrasonic Testing), RT (Radiographic Testing) and pressure or air-tightness tests. Each batch is supplied with EN 10204 3.1 material certificates, dimensional reports, NDT records, and clear markings of heat number and batch number, ensuring full traceability and long-term reliability in service.

Why Choose Chalco Titanium

Equipment & Capacity

Chalco Titanium operates its own CNC tube bending center, equipped with dedicated mandrels and die libraries covering 1D–10D bending radii. Laser cutting, automatic beveling (37.5° BE), ultrasonic cleaning and pickling lines are fully integrated. The complete process—bending, cutting, cleaning, inspection and packaging—is carried out in the same facility.

Quality & Consistency

Tooling solutions are designed according to drawing specifications and critical process parameters are locked in. All bends are delivered in Ready-to-Weld condition with clean surfaces and optional PE/BE/cut-to-length ends. Dimensional inspection reports and NDT records are provided with shipment. Standardized packaging (moisture barrier + protective caps + export wooden crates) ensures stability during transportation and on-site assembly.

Standards & Compliance

Raw tubes are manufactured according to ASTM B338, and finished bend pipes are produced and inspected in accordance with ASTM B363. Supply can also comply with ASME / DIN / EN requirements. Each delivery includes EN 10204 3.1 certificates with heat and batch number traceability. For projects requiring special standards (e.g. aerospace or medical), process documentation and quality control records can be provided as required.

Delivery & Service

Samples can be delivered in as fast as 7 days; normal batch production takes 2–4 weeks, depending on size and quantity. Technical engineers provide direct support, including R/D ratio optimization, assembly guidance and welding preparation. With multilingual technical communication and extensive international logistics experience, Chalco Titanium offers compliant documentation and reinforced export packaging for global shipments.

Full Titanium Pipe Product Coverage

As an integrated titanium pipe manufacturer and supplier, Chalco Titanium provides a complete portfolio covering different structures, grades, and manufacturing processes. In addition to Titanium Bend Pipe, we also supply Titanium Thin Wall Tube, Titanium Welded Pipe, Seamless Pipe, Square Tube, in Grade 2, Grade 5 and other hot selling alloys to meet various strength, pressure, and corrosion resistance requirements.

Whether your project involves precision tubing, structural piping systems, or customized processing solutions, our engineering team is ready to provide technical consultation and tailored manufacturing support. Contact us to discuss your specifications and receive a project-based quotation.

FAQ

Which titanium grade should I choose for bend pipes?

Common and stable grades include Grade 1 / 2 / 5 / 7 / 9 / 12.

- For thin-wall, small-radius bends and high consistency: choose Grade 1 / Grade 9 / Grade 2

- For chloride- or acid-containing media: choose Grade 7 or Grade 12

- For high-strength or load-bearing areas: Grade 5 can be considered (minimum bend radius often needs to be increased)

If unsure, provide the medium, temperature, pressure, and target bend radius, and we will advise on material selection and manufacturability.

Can small-radius or thin-wall bends be formed reliably?

Yes. For thin walls (≈0.5–2 mm) and 1D–3D small-radius bends, Mandrel Bending is recommended to control wrinkling and ovality with mandrels and wiper dies.

For large diameter/thick wall pipes or 2D–5D industrial pipelines, Hot Induction Bending is more suitable.

The final feasible bend radius must be evaluated based on OD / WT / grade.

What dimensions and tolerances can you achieve?

Typical capability: OD 5–114.3 mm, R = 1D–10D, angle 15°–180°, leg length 7″ / 9″ / custom.

All bending is measured based on centerline radius (CLR).

Angle, radius, ovality, wall thinning and other tolerances depend on the specification and process; confirmed tolerances are provided after drawing review.

Can it be used in seawater, chemical or high-temperature systems?

Yes, provided the material grade matches the design requirements.

- Seawater/chloride environments: Grade 7 or Grade 12

- Chemical and acidic media: corrosion resistance and weldability must be verified

- High temperature & pressure systems: wall thickness and design codes must be checked

We recommend providing operating conditions during the design stage for accurate material matching.

What standards do you follow, and what certificates can you provide?

Raw tubes are produced and inspected to ASTM B338; finished bend pipes are delivered per ASTM B363.

We can comply with ASME / DIN / EN project specifications when required.

Each delivery includes EN 10204 3.1 material certificate, dimensional report and NDT records, with full heat number and batch traceability.

How is pricing calculated?

Pricing is usually quoted per piece or per meter.

Factors affecting cost include: grade, OD/WT, bending radius & angle, tolerance, end type (PE/BE/cut), inspection requirements, quantity and delivery location.

After receiving drawings and quantities, we will provide a formal quotation and delivery schedule.

What about MOQ, samples and lead time?

Engineering samples and small batches are supported.

Lead time for samples and production depends on scheduling; expedited or partial delivery may be arranged if feasible.

The delivery time starts upon confirmation of drawings and commercial terms, and varies with size and quantity.

What is included in packaging and documentation?

Products are delivered in clean, Ready-to-Weld condition.

Standard packaging includes moisture protection, anti-scratch sleeves, and reinforced wooden crates, with heat/batch number labels for traceability.

Documentation typically includes EN 10204 3.1 certificate, dimensional report and NDT records; additional compliance documents can be arranged before order confirmation.