ERTi-1 Titanium Welding Wire

ERTi-1 Titanium Welding Wire is a Grade 1 commercially pure titanium filler metal compliant with AWS A5.16 standards. It is renowned for its high ductility and excellent corrosion resistance, ensuring dense, crack-resistant welds. Compatible with TIG (GTAW) and MIG (GMAW) processes, it is widely used in chemical processing vessels, explosive cladding plates, seawater desalination systems, and nuclear power equipment.

Choosing Chalco means securing full-process manufacturing assurance (melting–wire drawing–surface treatment), with the fastest 2-week delivery and ISO 9001 / AS9100 certification, guaranteeing consistent quality in every batch.

ERTi-1 Welding Wire Specifications

To meet diverse TIG (GTAW) and MIG (GMAW) welding needs, Chalco offers the following standard sizes, with custom lengths and flexible packaging options available:

| Item | ERTi-1 Filler Rod | ERTi-1 Spool Wire |

|---|---|---|

| Diameter Range | Ø1.0 / 1.6 / 2.0 / 2.4 / 3.2 mm | Ø0.8 / 1.0 / 1.2 / 1.6 mm |

| Length / Spool | 36 in (914 mm) | D-100 / D-200 / D-300 |

| Weight | 1–5 kg per tube | 5–15 kg per spool |

| Packaging | Plastic tubes / Carton box | Vacuum-sealed bag + Carton / Wooden box |

| Welding Process | TIG (Manual GTAW) | MIG (GMAW) |

| Surface Finish | Bright Annealed | Oxygen-free, Dry, Oil-Free |

| Standards | AWS A5.16, UNS R50100, AMS 4951 | |

| Welding Position | All Positions (Flat, Horizontal, Vertical, Overhead) | |

Technical Parameters & Standards

- AWS A5.16 – Specification for Titanium and Titanium-Alloy Welding Filler Metal

- UNS R50100 – Unified Numbering System designation for ERTi-1

- AMS 4951 – Aerospace material specification for titanium welding wire

Chemical Composition

| Element | Ti | Fe | O | C | N | H |

|---|---|---|---|---|---|---|

| Content | ≥99.5% | ≤0.08% | 0.03–0.10% | ≤0.03% | ≤0.03% | ≤0.005% |

Mechanical Properties

| Property | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| Value | ≥275MPa | ≥170MPa | ≥25% |

GTAW (TIG) Welding Parameters

| Wire Diameter | Voltage (V) | Current (A) | Shielding Gas |

|---|---|---|---|

| Ø 1.6 mm | 14 – 18 | 90 – 130 | 100% Argon |

| Ø 2.4 mm | 15 – 20 | 120 – 175 | 100% Argon |

| Ø 3.2 mm | 15 – 20 | 150 – 220 | 100% Argon |

GMAW (MIG) Welding Parameters

| Wire Diameter | Voltage (V) | Current (A) | Wire Feed Speed (m/min) | Shielding Gas |

|---|---|---|---|---|

| Ø 0.8 mm | 16 – 20 | 100 – 195 | 3.0 – 6.0 | Argon or Ar + He mixture |

| Ø 1.0 mm | 18 – 27 | 165 – 285 | 4.0 – 8.0 | Argon or Ar + He mixture |

| Ø 1.2 mm | 28 – 32 | 180 – 220 | 5.0 – 9.0 | Ar + 25% He |

| Ø 1.6 mm | 29 – 33 | 200 – 250 | 6.0 – 10.0 | Ar + 25% He |

Contact us to get the complete Welding Procedure Specification (WPS) and Chalco engineering support, ensuring efficient welding and high-quality joints.

Next, let's explore the key advantages of ERTi-1 and why it is the ideal solution for chemical processing and corrosion-resistant applications.

Why Choose ERTi-1? Key Performance Advantages

- Excellent Ductility: AWS A5.16 ERTi-1 offers an elongation rate of ≥ 25%, delivering strong weld toughness and preventing hot cracking. It is ideal for deep-drawn parts, thin-wall welding, and complex structures.

- Outstanding Corrosion Resistance: Resistant to chlorides, acidic media, and seawater environments, making it highly suitable for chemical equipment and desalination heat exchangers.

- Stable Welding Performance: Compatible with both TIG (GTAW) and MIG (GMAW) processes, requires no preheating, provides smooth bead appearance, and exhibits low susceptibility to hot cracking.

- Reliable in Harsh Conditions: Performs consistently in high-humidity and highly corrosive environments, extending equipment service life and reducing maintenance costs.

Typical Applications & Industry Solutions for ERTi-1 Welding Wire

Chemical Processing

Description: Reactors and storage tanks face acidic and chloride media, demanding welds with high corrosion resistance and ductility. ERTi-1 filler wire prevents stress corrosion cracking.

Typical Applications: Reactor linings, acid tanks, pipelines, storage tanks.

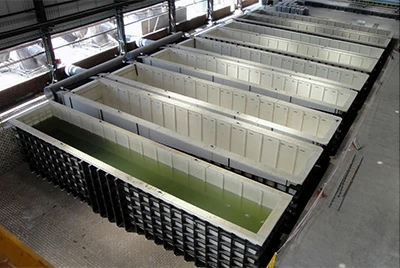

Desalination & Heat Exchangers

Description: In desalination and cooling systems, welds must resist pitting and crevice corrosion in high-salinity environments. ERTi-1 provides consistent corrosion protection for long-term immersion and humid operating conditions.

Typical Applications: Evaporator tube sheets, condenser bundles, heat exchanger shells.

Explosive Cladding Applications

Description: As a filler metal for explosive clad plates, ERTi-1 ensures flexible, dense welds that prevent delamination at the interface, meeting the stringent safety standards for petrochemical and pressure vessel applications.

Typical Applications: Titanium-steel transition welds, clad pressure vessel fabrication.

Nuclear & Pressure Vessels

Description: Nuclear systems require clean, corrosion-resistant weld joints to maintain integrity under extreme conditions. ERTi-1's low oxygen content guarantees excellent weld toughness, reducing defects and ensuring long-term structural reliability.

Typical Applications: Nuclear heat exchanger tube bundles, corrosion-resistant pipelines, liner welding.

If you are considering whether to choose ERTi-1 or ERTi-2, the next section provides a side-by-side comparison to help you make the best decision.

ERTi-1 vs. ERTi-2 Titanium Welding Wire

| Comparison Item | ERTi-1 | ERTi-2 |

|---|---|---|

| Chemical Composition | Ti ≥ 99.5%, O: 0.03–0.10%, Fe ≤ 0.08%, H ≤ 0.005% | Ti ≥ 99.2%, O: 0.08–0.16%, Fe ≤ 0.10%, H ≤ 0.005% |

| Tensile Strength | ≥ 275 MPa | ≥ 345 MPa |

| Yield Strength | ≥ 170 MPa | ≥ 275 MPa |

| Elongation | ≥ 25% (Excellent Ductility) | ≥ 20% |

| Key Features | High ductility, excellent weldability, superior corrosion resistance | Higher strength with good corrosion resistance, good weldability |

| Suitable Base Material | ASTM Gr.1 titanium, clad plates, chemical equipment | ASTM Gr.2 titanium, heat exchangers, pressure vessels |

| Typical Applications | Chemical containers, desalination units, explosive cladding, nuclear heat exchangers | Pressure vessels, heat exchangers, petrochemical equipment, structural components |

- When your project requires maximum corrosion resistance and superior ductility, the best choice is ERTi-1.

- For applications demanding higher pressure resistance, the preferred option is ERTi-2.

After selecting the right grade, ensuring supply reliability and delivery speed is essential. Next, discover Chalco's production capabilities and service advantages.

Why Choose Chalco: Production Capability & Service Advantage

Full Supply Chain Assurance: Consistent Quality, Flexible Delivery

- In-House Production Line: From melting, wire drawing, surface treatment to precision finishing, Chalco controls the entire process to ensure material consistency and process stability.

- Complete Product Coverage: We provide a full range of titanium welding wire solutions, covering multiple grades and specifications for diverse industrial applications.

- Flexible Delivery: Standard lead time 4–6 weeks, samples within 2 weeks, with expedited production available to keep your projects on schedule.

International Certifications & Strict Quality Control

- Certified Systems: All welding wires are produced under ISO 9001 and AS9100 quality management systems, guaranteeing compliance with international standards.

- Quality Testing: Every batch undergoes chemical composition analysis, tensile testing, and surface cleanliness inspection to ensure high weld integrity.

- Third-Party Verification: SGS, BV certifications available; products meet EN 10204 3.1 standards for full traceability.

Customization & Technical Support

- Multiple Titanium Grades Available: Including industry-standard grades such as ER Ti-2 welding wire and ER Ti-5 welding wire, suitable for corrosion-resistant and high-strength structural applications.

- Custom Options: Available in welding rods (straight cut welding rods) and spooled wires, with private labeling and various packaging configurations to meet specific project requirements.

- Engineering Support: Our technical team provides welding parameter recommendations and assistance with welding procedure qualification (WPQ).

- Sample Support: Free samples available for trial welding to ensure process compatibility and welding performance.

Chalco delivers comprehensive supply chain assurance, flexible customization, and globally recognized certifications—ensuring every batch meets your quality standards and delivery timelines. Whether for initial trials or large-scale production, Chalco partners with you to guarantee welding reliability and process success.

FAQs

Why is ERTi-1 welding wire widely used in explosive cladding?

Explosive cladding requires filler metals with exceptional toughness and ductility to absorb impact energy and prevent weld cracking. ERTi-1, with low oxygen content and superior plasticity, produces dense welds that ensure a strong titanium-to-steel bond, preventing delamination—making it the preferred filler metal for clad plate welding.

How does ERTi-1 ensure corrosion resistance in chemical vessels and heat exchangers?

Made from commercially pure titanium, ERTi-1 provides excellent resistance to chlorides, acidic media, and seawater. Chalco strictly controls oxygen, iron, and hydrogen content for maximum purity, and applies acid pickling and passivation prior to delivery, ensuring long-term performance in chlor-alkali, electrolysis, and marine environments.

What is the difference between ERTi-1 and ERTi-2?

ERTi-1 has lower oxygen content and better ductility, ideal for high-corrosion resistance and low-stress environments. ERTi-2 contains slightly more oxygen, resulting in higher strength, making it better suited for pressure-rated components.

Why choose ERTi-1 instead of ERTi-2?

If your priority is corrosion resistance and superior weld formability—especially for deep-drawn parts, thin-wall joints, or low-stress applications—choose ERTi-1. For components requiring greater structural strength, ERTi-2 is the preferred option.

What special TIG welding practices are required for ERTi-1?

Use argon gas with ≥99.99% purity, keep the weld area clean and oil-free, and apply back purge shielding to prevent root oxidation. Maintain low heat input to reduce weld embrittlement risk.

Can Chalco provide small-quantity trial samples?

Yes. Chalco offers free samples (standard lengths or spooled wire) for pre-production welding trials, helping clients validate processes and reduce risk before bulk procurement.

How does Chalco ensure ERTi-1 products meet standards and minimize risk?

All welding wires are manufactured to AWS A5.16 / EN ISO 24034, with EN 10204 3.1 material certificates provided. We support third-party inspections (SGS, BV) to ensure traceability and compliance with customer standards.