High-Performance Titanium Spring Wire

In demanding applications that require ultra-lightweight, long fatigue life, and superior corrosion resistance, traditional metal springs are increasingly showing their limitations.

Titanium Spring Wire offers an exceptional strength-to-weight ratio, fatigue resistance, and corrosion performance, making it the preferred spring material in high-end industries such as aerospace, medical devices, and precision electronics.

Chalco Titanium supplies high-performance titanium spring wire compliant with ASTM B863, ASTM F136, ASTM F67, AMS 4954, ISO 13485, and ISO 10993. We support full-range customization from Ø 0.10 to 5.00 mm, meeting your requirements for lightweight design, harsh operating environments, and long-term reliability.

Up to 70% weight reduction, twice the fatigue life, and resistance to seawater and strong acids — Request your free sample today, shipped within 3 days.

Why Choose Titanium Spring Wire?

In extreme working conditions involving lightweighting, corrosion resistance, and high fatigue loads, titanium spring wire delivers performance advantages far beyond traditional steel. These five key features are driving its growing adoption in precision spring manufacturing:

Ultra-Lightweight & High Strength

With a density of just 4.43 g/cm³, titanium spring wire reduces weight by over 70% compared to conventional steel, while offering tensile strengths up to 950–1100 MPa. This enhances load-bearing capacity per unit mass—ideal for lightweight design and energy efficiency.

Typical applications: UAV spring assemblies, aerospace electromechanical systems, racing suspension springs.

Outstanding Corrosion Resistance

A naturally formed titanium oxide film provides superior corrosion resistance, enabling long-term stability in seawater, high humidity, and acidic or alkaline environments—without additional surface protection or frequent replacement.

Typical applications: Marine springs, chemical control valve springs, medical device springs.

Excellent High-Temperature Stability

Titanium wire maintains strength and elasticity at continuous operating temperatures above 300°C, with low creep and minimal performance degradation. It is ideal for high-temperature and thermal cycling environments.

Typical applications: Turbine systems, hot-end valve springs, engine compartment springs.

Superior Fatigue Life

With high fatigue strength and low stress relaxation, titanium spring wire is ideal for long-duration, high-frequency cyclic applications. Tested to exceed 10 million fatigue cycles, its durability benefits from a modulus of elasticity of 15.5×10⁶ psi and shear modulus of 6.0×10⁶ psi, minimizing crack propagation and ensuring structural integrity under repeated loads.

Typical applications: Mechanical stamping springs, surgical medical springs, precision electrical connector springs.

Biocompatible & Non-Magnetic

Medical-grade titanium alloys, certified to ASTM F136 and ISO 10993, offer excellent biocompatibility and are non-magnetic—safe for use in-body or in imaging environments.

Typical applications: Cardiovascular stent springs, neurostimulator coils, MRI-safe spring components.

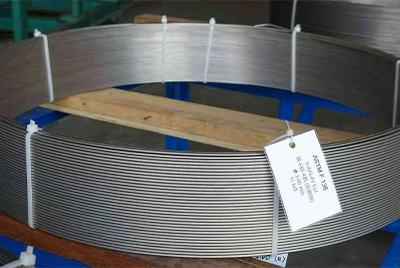

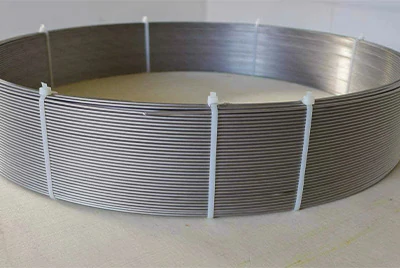

Product Forms of Titanium Spring Wire

Titanium spring wire is more than just a wire — it is the foundational element for building lightweight, high-strength spring structures. We offer a wide range of shapes, dimensions, and processed conditions to suit different spring types and precise forming requirements.

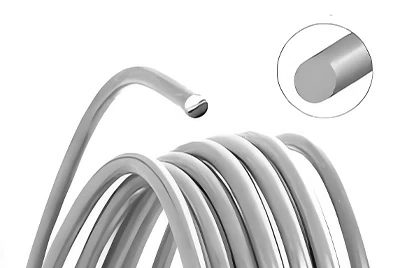

Round Titanium Spring Wire

Diameter: Ø 0.10–5.00 mm

Features: Excellent formability, widely applicable

Applications: Compression springs, extension springs, torsion springs

Place Order

Flat Titanium Wire

Thickness: 0.15–3.0 mm Width: 1–12 mm

Features: Larger contact area, ideal for flat-space designs

Applications: Wave springs, leaf springs, rectangular section springs

Place OrderSquare Titanium Spring Wire

Dimension: 0.50–4.00 mm

Features: Clean edges, evenly distributed stress

Applications: Torque springs, stop-position springs

Place Order

Custom-Shaped Titanium Wire

Shapes: Wedge, trapezoid, grooved, etc.

Features: Stress optimization, enhanced functional fit

Applications: Precision fasteners, special-load spring elements

Place OrderNot sure which wire profile fits your application best? Contact us for expert guidance and tailored recommendations → Contact us

Titanium Wire for Multiple Spring Structures

Titanium wire offers excellent formability and elastic strength, enabling it to be processed into various spring structures. It is widely used across load-bearing, extension, torsion, damping, and balance scenarios. Below are the typical spring types supported by our titanium wire:

-

Compression Springs

The most common spring type, designed to withstand axial loads.

Typical uses: medical syringes and shock absorption systems.

-

Extension Springs

Equipped with end hooks to store tensile force and return to position.

Common in: door control mechanisms, cables, and sports equipment.

-

Torsion Springs

Store mechanical energy through torque.

Can be formed into: various leg shapes for automatic mechanisms and hinge systems.

-

Wave Springs

Ideal for confined spaces, providing multi-peak elastic behavior.

Used in: precision instruments and valve assemblies.

-

Counterbalance Springs

Maintain stable positioning in open-close motions.

Found in: windows, lids, and load-bearing mechanisms.

-

Die Springs

Designed for high impact and large deflection.

Ideal for: mold tooling, jigs, and heavy-duty load systems.

-

Leaf Springs (Flat Springs)

Strip-shaped with both stiffness and flexibility.

Widely used in: electrical contacts, sensor devices, and test probes.

These spring types represent the most common structural applications of our titanium wire. More importantly, they are not just theoretical uses — our products have been successfully implemented in real-world projects by customers across aerospace, medical, and precision engineering industries.

Note: Chalco Titanium does not manufacture finished springs. We supply high-quality titanium wire as raw material for spring producers, compatible with downstream cold forming, heat treatment, and surface finishing processes.

Real Springs, Powered by Chalco Titanium Wire

While Chalco Titanium does not manufacture finished springs, our titanium spring wire has been widely adopted by high-end clients worldwide for producing various high-performance spring structures. The following examples showcase actual spring products made from our titanium wire. These real-world applications not only demonstrate excellent formability and reliability but also offer valuable reference for your own design and material selection.

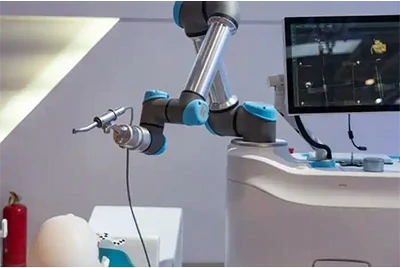

Medical Springs

Used in surgical forceps, catheters, and vascular stents. Made from ASTM F136-compliant wire with full biocompatibility and non-magnetic properties.

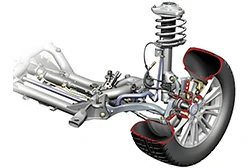

Conical Racing Suspension Springs

Tapered helical springs used in high-performance shock absorbers, commonly found in racing cars, motorcycles, and off-road systems.

Dual-Wire Custom Springs

Compact structure for temperature-controlled skylights and automated window systems, offering long-term stability under repeated actuation.

Tent Guyline Springs

Corrosion-resistant and fatigue-proof, used in outdoor gear to enhance wind resistance and structural flexibility.

NiTi Shape Memory Springs

Provide superelasticity and thermo-responsive actuation, ideal for implantable medical devices, micro-actuators, and sensing systems.

Clothespin Torsion Springs

Precisely formed and dimensionally stable, used in clamps, stationery clips, and similar everyday fixtures.

As you can see, Chalco's titanium spring wire has been successfully integrated into real-world products across sectors like medical devices, suspension systems, and outdoor equipment.

Industry Applications of Titanium Spring Wire

Thanks to its exceptional strength-to-weight ratio, fatigue resistance, and corrosion resistance, Chalco's titanium spring wire has been widely adopted in critical spring components across industries such as aerospace, medical devices, high-performance sports equipment, and precision electronics.

Aerospace

Compression and torsion springs made from titanium wire are used in engine components, hydraulic hatches, and seat dampers. These springs offer lightweight durability and fatigue resistance under high temperatures and continuous vibration.

Contact us now

Medical Devices

Medical-grade titanium wire is formed into stent rings, catheter springs, and surgical tool arms. It provides excellent biocompatibility and non-magnetic properties, suitable for sensitive environments such as MRI suites.

Contact us nowHigh-End Sports Equipment

Titanium spring wire is applied in racing shock absorbers, bike fork suspensions, and trekking pole dampers. It combines lightweight performance with high responsiveness, serving as a superior alternative to aluminum or steel springs.

Contact us now

Motion Control Systems

Custom-shaped titanium springs are used in temperature-controlled windows, automated doors, and unmanned equipment, delivering reliable self-resetting and precise force control.

Contact us nowConsumer Electronics & Precision Instruments

Titanium leaf springs and micro coil springs are integrated into battery contacts, miniature sensors, and aviation connectors, offering consistent elasticity and miniaturized compatibility.

Contact us now

Looking for a spring material that delivers lightweight strength and extreme durability in harsh environments?

Chalco's titanium spring wire has proven its value across industries.

Technical Specifications of Titanium Spring Wire

| Common Grades | Gr1, Gr2, Gr3, Gr5, Gr9, Gr23, NiTi (Nitinol) |

| Delivery Condition | Annealed, Cold Worked |

| Round Wire Diameter | 0.1 – 5.0 mm (customizable) |

| Square Wire Size | 0.5 – 4.0 mm (edge length) |

| Flat Wire Size | Thickness: 0.15 – 3.0 mm Width: 1.0 – 12.0 mm |

| Surface Finish | Pickled, Bright, Polished, Passivated |

| Dimensional Tolerance | Up to ±0.01 mm |

| Length Form | Coil, Straight Rod, Cut-to-Length |

| Standards | ASTM B863 / F136 / F67, AMS 4951 / 4954, ISO 13485 / 10993, GB/T 3623 / 13810 |

Chalco Titanium has consistently supplied high-quality titanium spring wire to over 100 spring manufacturers worldwide. We welcome you to be the next success story. Place Your Order

Technical Tip – Quick Selection Guide

| Application Scenario | Material | Size Range | Key Features |

| Micro springs for stents / guidewires / staplers | Gr23 / NiTi | Ø 0.2 – 1.2 mm | Biocompatible, non-magnetic, fatigue-resistant, supports shape memory |

| Racing / motorcycle suspension coil springs | Gr5 / Gr9 | Ø 2.0 – 5.0 mm | High strength, high temperature resistant, stable rebound |

| Eyewear hinges / frame positioning wire | Gr2 / Gr3 | Ø 0.3 – 1.0 mm | Ultra-lightweight, high flexibility, long-term corrosion resistance |

| Tent hooks / climbing clips | Gr2 / Gr3 | Ø 0.8 – 2.5 mm | Excellent formability, seawater resistant, suitable for outdoor conditions |

| Torsion springs for auto windows / tools | Gr5 / Gr9 | Ø 1.0 – 4.0 mm | Strong torsional rigidity, long fatigue life, cold coiling compatible |

| Battery contacts / precision clips (electronics) | Gr5, Square/Flat Wire | Square: 0.5–2.0 mm Flat: 0.2–0.8 mm | High strength, good conductivity, ideal for compact electronic assemblies |

| Return & locator springs for power tools | Gr5 / Gr9 | Ø 1.0 – 3.5 mm | Impact-resistant, fatigue durable, supports mass cold forming |

| Thrust / leaf springs for precision tooling | Flat Wire (Gr5) | Thickness: 0.3–2.0 mm Width: 2–10 mm | Accurate rebound control, excellent wear resistance, for long-term mold operation |

| Shock springs in aerospace / defense | Gr5 / Gr9 / Gr23 | Ø 2.5 – 5.0 mm | Stable under extreme conditions, usable in –100°C to 300°C |

| Shape memory springs | NiTi | Ø 0.2 – 1.0 mm | Shape memory effect, superelastic, suitable for micro-actuation systems |

Not sure which titanium grade is best for your application? Tell us about your operating conditions, spring type, and performance requirements — we'll recommend the optimal material and specs for your project. Get Expert Advice

Supply Capability & Quality Assurance

We provide more than just titanium wire — we ensure fast delivery, certified quality, and global service support.

Full-Series Titanium Wire Supply

We offer a complete range of titanium wire products, covering all major types to meet diverse industrial and medical applications. Our catalog includes standard industrial wires, specialized 3D titanium wire, high-strength welding rods, and cable materials. Whether you need titanium cable material, 3D titanium wire, or titanium welding rods, our full-series supply ensures your project needs are fully covered.

Fast Delivery

We maintain stock of standard titanium wire specifications and offer made-to-order options in both coil and straight-cut forms. Custom samples can typically be shipped within 3–5 days, while standard bulk lead times are 7–14 days. This supports fast-paced development and production cycles for spring manufacturers and other industrial users.

Full-Process Quality Inspection

Each batch is subject to strict quality control, including Eddy Current Testing (ET) and Ultrasonic Testing (UT) for non-destructive inspection. Upon request, we also provide shot peening, dye penetrant inspection, and other advanced services to ensure both internal and surface integrity.

Complete Certification

Chalco Titanium operates under international quality systems, including ISO 9001, AS9100 (Aerospace), and ISO 13485 (Medical Devices). Each shipment comes with a Certificate of Analysis (COA) and optional third-party test reports (e.g., SGS / BV).

Global Logistics & Support

We support UPS / DHL air freight and FOB / CIF sea freight terms, covering key industrial regions such as Europe, North America, Japan, and Southeast Asia. Professional export packaging and after-sales tracking ensure safe and timely delivery.

Need to check inventory, lead time, or request samples and inspection reports?

Contact us for one-on-one technical consultation and quotation.

FAQ

Is titanium spring wire significantly more expensive than stainless steel wire?

Yes, the unit price of titanium wire is typically 2 to 4 times higher than that of premium stainless steel. However, due to its lower density, longer service life, and natural corrosion resistance (no need for coating), it offers reduced replacement frequency and lower long-term maintenance costs, making it ideal for high-value applications.

Which titanium grade is recommended for seawater or chemical environments?

We recommend Gr2, Gr5, or Gr9, which provide excellent chloride corrosion resistance. For medical or sensitive devices, Gr23 (Ti-6Al-4V ELI) is preferred to ensure biocompatibility.

Do your titanium wires comply with AMS and ASTM standards?

Yes. We supply titanium spring wire in full compliance with the following international standards:

- ASTM B863 – General standard for titanium and titanium alloy wire

- AMS 4951 / AMS 4954 – Aerospace-grade titanium alloy wire

- ASTM F136 / F67 – Medical implant-grade titanium alloys

- ISO 13485 / ISO 10993 – Medical device quality systems and biocompatibility certification

What is your minimum order quantity (MOQ)? Do you offer samples?

For standard sizes, our MOQ is as low as 1 kg, and free samples (typically 0.3–1.0 kg) are available depending on alloy grade and size. Special-shaped wires may require higher starting quantities.

Can I specify surface finish or treatment options?

Absolutely. We offer a variety of finishes including pickled, polished, bright, sandblasted, and passivated. Please indicate your requirements during inquiry — we will recommend the most suitable treatment for your application.

Do you support cut-to-length, custom packaging, or laser marking?

Yes. We offer cut-to-length service (tolerance ±0.5 mm), vacuum packaging, spool/coil formats, and laser marking (grade/batch info), meeting traceability needs for medical and aerospace sectors.

Still have technical or purchasing questions?

Our engineering team is here to help — Contact Us for tailored advice and solutions. Quick Quote