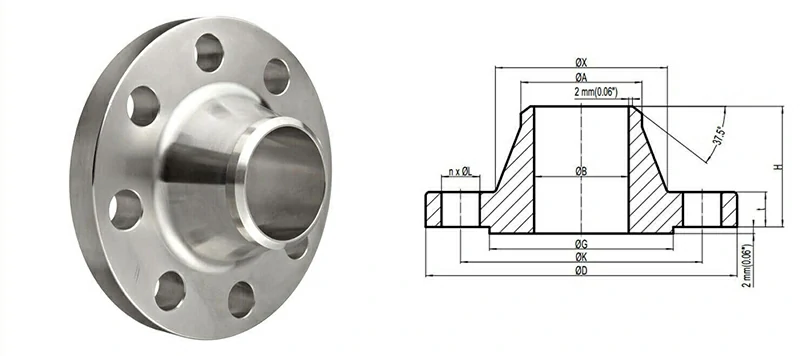

Ti Weld Neck Flange

Updated : Jun. 23, 2025A titanium weld neck flange has a tapered neck between the flange ring and the pipe. It is fully butt-welded to the pipe. This design moves stress away from the sealing surface. Weld integrity can be tested by RT or UT. Titanium's natural oxide film makes it maintenance-free and corrosion-resistant in seawater, chlorides, and most organic acids.

- Ti-6Al-4V (GR5) has a density of about 4.43 g/cm³, only 55% of 316L stainless steel. Its tensile strength at room temperature is about 895 MPa, 1.7 times that of 316L. This allows weight reduction while improving design pressure.

- In natural or chlorinated seawater, the overall corrosion rate is negligible. The maximum temperature can reach 260°C. However, local corrosion may occur if crevices form above 80°C.

Available Specifications

| Selection Dimension | Our Stock / Custom Range | Purchase Value | Notes |

|---|---|---|---|

| Nominal Size | ½″ – 24″ (ASME B16.5) | Small sizes in stock, large sizes deliverable in 30 days | B16.47 A has fewer bolts and faster assembly; B has higher load capacity |

| ≥ 26″ follow B16.47 A/B | |||

| Pressure Class | Class 150 – 1500 / PN 6 – 260 bar | Covers 90% of high corrosion, high pressure conditions | Commercial upper limit of titanium forgings usually Class 1500 (verified) |

| Sealing Face Type | RF (standard); RTJ (recommended for Class ≥ 600 or low leak projects) | Choose gasket or metal ring by your leak requirements | RTJ fits R/RX/BX metal ring gasket; RF fits flexible gasket |

| Neck Wall Thickness | SCH 10S – 160 | Matches pipe wall thickness, no need for reducers | Made per ASTM B381 forgings |

How to Choose Titanium Alloy by Working Condition?

| Condition / Concern | Preferred Grade | Advantage in One Sentence | Typical Tensile Strength / MPa* | What We Can Provide |

| Seawater, RO desalination, pure water systems, mild corrosion, want 15-20 years maintenance free | GR2 (CP-Ti) | General chlorine resistance, lowest cost | ≈ 344 | Stock available, ½″-12″ regular stock, EN 10204-3.1 certificate |

| Chlor-alkali, electrolysis, wet chlorine or sulfur environments, worry about crevice/pitting corrosion and high repair cost | GR7 (Ti-0.2 Pd) | Palladium alloyed, crevice corrosion resistance up to 250 °C | ≈ 345 | Custom-made for projects, Class 150-600, 3-4 weeks delivery |

| High-pressure steam, subsea oil extraction, weight-limited equipment, must be light, strong, and withstand 300 °C thermal cycles | GR5 (Ti-6Al-4V) | Strength about 1.7 times 316L, weight only 55% | ≈ 895 | Class 900-1500 RTJ face available, with Inconel ring gasket |

*Mechanical properties are typical values. Actual values vary with size and heat treatment. Original MTR included.

Selection formula: medium corrosion → max P/T → pipe size → standard / sealing face.

Why This Classification?

- GR2 is the "commuter" choice: best cost-performance unless strong oxidants or crevices exist.

- GR7 is the "tough" choice: Pd improves oxide film stability, can handle wet chlorine and acid mist.

- GR5 is the "high strength lightweight" choice: ideal for offshore, pressure vessels needing weight reduction or Class 900+.

Corrosion Resistance in Seawater and Chloride Environments

CP-Ti corrodes less than 0.0005 mm/year in oxygenated seawater. Max corrosion resistance temperature is 260 °C. Crevice corrosion starts around 80-90 °C.

Palladium alloy (GR7) raises crevice corrosion temperature to about 250°C. It maintains passive film even in concentrated brine or acidic chloride media.

Industry Application Cases

Seawater Desalination | Large Israeli RO Plant

Converts 620,000 m³ seawater daily to drinking water with 20-year design life. Uses 28″ Class 300 GR7 weld neck RTJ flanges on high-pressure inlet. Pd alloy titanium's crevice resistance avoids anodes or frequent repairs. Stable operation with zero leaks or replacements.

Deepwater Oil & Gas | FPSO Riser System, Offshore Brazil

200 km offshore FPSO limited by deck weight, must handle 90 bar sour crude with H₂S. Owner required 6″ Class 600 GR5 weld neck RTJ flange as sole option. This reduces weight and withstands 300°C thermal cycles and H₂S stress corrosion. Made per ASME B16.5 with Inconel RX ring gasket, passed DNV witness testing, in service 4 years.

Chlor-Alkali Chemical | Southeast Asia Chain Bleaching Area

Wet chlorine and hypochlorite cause 316L to pit and leak within 6 months. In 2018, switched to 10″ Class 150 GR7 weld neck RF flange and PTFE-edged flexible graphite gasket. After 5 years, only routine PMI tests, no corrosion failures; annual downtime reduced from 7 to 2 days, saving about \$200,000 production loss yearly.

Want to know the best titanium alloy for your conditions? Send medium, max temperature & pressure, and pipe size to mailto:contact@chalcoaluminum.com.

Quality and Inspection Key Points

| Inspection | Standard | Purpose |

| PMI Spectrum | ASTM E1476 | Confirm chemical composition |

| UT / RT | ASME V | Exclude internal defects in forgings |

| PT | ASME V | Inspect weld microcracks |

| Hydrostatic Test | ASME B16.5 Appendix A | Verify pressure rating |

| Material Certificate | EN 10204 3.1 / 3.2 | Full material traceability |

Purchase Tips

- MOQ: Stock specs can be ordered as 1 piece; custom large sizes recommended ≥ 5 pcs to spread forging cost.

- Delivery: ≤ DN300 standard RF face 7-10 days; RTJ or > DN600 about 20-30 days.

- Packaging: PE film + desiccant + fumigated wooden box with humidity indicator card.

- Documents: MTR, EN 10204-3.1/3.2, NACE MR0175 compliance, third-party witness (BV/DNV) optional.

- Value-added: Matching titanium bolts and gaskets; "pressure-temperature-size" selection table provided within 24h.

Complete Titanium Flange Product Range

In addition to Titanium Weld Neck Flange solutions, Chalco Titanium supplies a full range of titanium flanges designed for different pressure classes and connection types. Our portfolio includes Titanium Threaded Flange, Titanium Lap Joint Flange, Titanium Slip On Flange, Titanium Blind Flanges, as well as a complete Titanium Flanges product line for industrial piping systems.

With integrated forging, machining, heat treatment and inspection capabilities, we ensure dimensional accuracy, pressure integrity, and long-term corrosion resistance. Whether your project requires high-pressure structural flanges or specialized connection solutions, our engineering team is ready to support customized manufacturing and global delivery.

FAQ

Q1: Can Ti weld neck flange replace carbon steel or stainless steel directly?

Check pipe compatibility. If original pipe is carbon steel, add a titanium-to-steel transition spool before welding.

Q2: Is RTJ face mandatory?

For Class > 600 or zero-leak projects (ISO 15848-1), RTJ is preferred. For medium-low pressure, RF can reduce cost.

Q3: Is welding difficult?

Requires full inert gas shielding. If weld zone > 400°C, double-sided argon protection needed. Recommended filler: ERTi-2 or ERTi-5.

Titanium weld neck flanges, with their lightweight strength and excellent corrosion resistance, are rapidly replacing 316L and 2507 materials. If your system faces high chloride, high pressure, or frequent repairs, upgrading to titanium flanges can pay off within one maintenance cycle.

Send your working conditions to [contact@chalcoaluminum.com]. We will provide a customized cost-benefit analysis within 24 hours.