Titanium Slip-On Flange ½–24: Fast Assembly Corrosion Guard

Updated : Jun. 23, 2025What Is a Titanium Slip-On Flange?

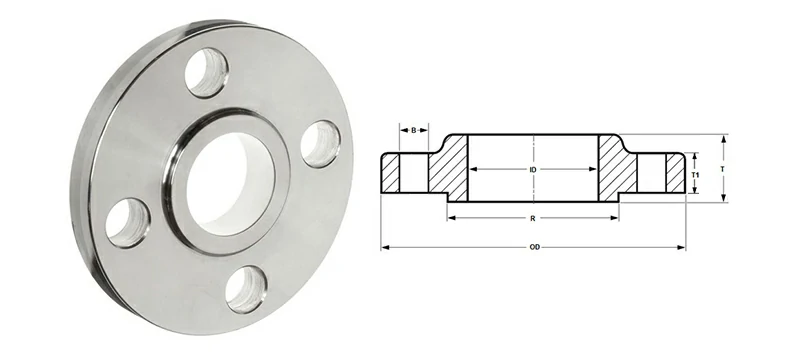

A slip-on flange is a ring-shaped flange that slips over the pipe's outer diameter and is welded on both the inside and outside faces, eliminating the bevel-preparation steps required for weld-neck flanges.

Made from Grade 2 or Grade 5 titanium, these flanges combine superior corrosion resistance with a weight that's about half that of a stainless-steel equivalent.

Full Size Chart (½″–24″)

Compliant with ASME B16.5, covering sizes from ½″ to 24″, and available in Raised Face (RF) or Ring Type Joint (RTJ) configurations.

| Nominal Size | Outside Diameter OD (in) | Thickness t (in) | Flange Height H (in) | Bolt Qty × Bolt Diameter (in) | Weight (lbs / kg) |

| ½″ | 3.5 | 0.44 | 0.88 | 4×0.50 | 0.94 / 0.43 |

| ¾″ | 4 | 0.5 | 1 | 4×0.63 | 1.20 / 0.54 |

| 1″ | 4.5 | 0.56 | 1 | 4×0.63 | 1.75 / 0.79 |

| 1½″ | 5.75 | 0.63 | 1.25 | 4×0.63 | 2.75 / 1.25 |

| 2″ | 6 | 0.63 | 1.12 | 4×0.63 | 3.50 / 1.59 |

| 3″ | 7.5 | 0.75 | 1.5 | 6×0.69 | 5.50 / 2.50 |

| 4″ | 9 | 0.94 | 4.57 | 8×0.63 | 8.13 / 3.69 |

| 6″ | 11 | 1 | 6.72 | 8×0.75 | 12.25 / 5.56 |

| 8″ | 13.5 | 1 | 7 | 8×0.75 | 18.00 / 8.16 |

| 10″ | 15.75 | 1.12 | 7.5 | 12×0.88 | 25.00 / 11.34 |

| 12″ | 18 | 1.25 | 8 | 12×0.88 | 32.00 / 14.51 |

| 16″ | 23 | 1.5 | 9 | 16×0.88 | 50.00 / 22.68 |

| 20″ | 28 | 1.62 | 9.5 | 16×0.88 | 70.00 / 31.75 |

| 24″ | 33 | 1.75 | 10 | 20×1.00 | 95.00 / 43.09 |

Alloy Grades & Corrosion Resistance

Grade 2 Titanium (CP-Ti): General corrosion resistance, oxygen ≤ 0.2%, ideal for seawater and common chemical media.

Grade 5 Titanium (Ti-6Al-4V): High strength, service temperature up to 400 °C, suitable for high-pressure and high-temperature applications.

Non-Destructive Testing & Certifications

PMI (Positive Material Identification) to verify alloy grade.

UT/PT (Ultrasonic & Penetrant Testing) for lamination and leak detection.

EN 10204 3.1 Inspection Report and PED/ASME compliance.

Third-party inspection (SGS/BV) typically USD 400–500 per batch.

Our Services

Our minimum order quantity is 5–10 pieces, and mixed-size orders are supported; payment terms are a 30% deposit and 70% before shipment, with letters of credit also accepted.

The standard lead time is 12–15 days, and urgent orders can be expedited to 3–5 days.

The flanges are produced strictly in accordance with ASME B16.5, covering the full ½″–24″ range and offered in Raised Face (RF) or Ring Type Joint (RTJ) facings.

All flange surfaces are controlled to a roughness of Ra ≤ 0.15 mm and a flatness of ≤ 0.15 mm to ensure excellent sealing performance and minimal leakage risk.

The innovative slip-on bevel-free design requires only a single circumferential weld for installation, improving assembly efficiency by about 22% compared to traditional weld-neck flanges..

Customer Case Studies

In the Texas LNG project in the U.S., we delivered 220 pieces of 6″ 150 LB GR2 titanium slip-on flanges under DDP Houston terms, saving 14% per unit compared to duplex steel of the same specification.

In a German chemical plant project, the customer ordered 60 pieces of 3″ 300 LB GR5 titanium slip-on flanges on EXW terms. Compliance with PED and REACH added 9% to the cost, but shortened the approval process by two weeks, greatly improving project efficiency.

In the Abu Dhabi seawater desalination plant project in the UAE, we delivered 150 pieces of 2″ 150 LB GR2 titanium slip-on flanges under FOB Dubai terms, saving about 18% in material costs versus SS 304 flanges of the same size, and reducing logistics costs by approximately USD 2.50 per piece, significantly lowering total lifecycle procurement and transport expenses.

In the Yokohama petrochemical plant project in Japan, we delivered 80 pieces of 10″ 300 LB GR5 titanium slip-on flanges under DDP Yokohama terms, cutting overall costs by around 12% compared to carbon steel flanges, and thanks to the bevel-free single-weld design, on-site welding time was reduced by about 30%, markedly saving labor costs and shortening the construction schedule.

Comprehensive Titanium Flange Supply

Alongside Titanium Slip On Flange solutions, Chalco Titanium offers a full range of titanium flange products for different installation and pressure requirements. Our product line includes Titanium Weld Neck Flange, Titanium Threaded Flange, Titanium Lap Joint Flange, Titanium Blind Flanges, as well as the complete Titanium Flanges system.

Through advanced forging, precision machining, and strict inspection procedures, we ensure reliable sealing surfaces and long service life in corrosive and high-pressure environments. For project inquiries or technical consultation, our engineering team is available to provide tailored support.

Get Your Quote in 24 Hours

Required Information: Pipe OD/ID, wall thickness, pressure rating, alloy grade, surface roughness, inspection scope, delivery port (e.g., "DDP Houston”).

Smart XLS Form: Built-in formulas auto-calculate weight and machining time, enabling price locking within one business day.

Common Terms & FAQs

Payment Terms: 30% TT in advance, balance before shipment; ≤ 100 pcs lead time 12–15 days; orders > USD 30 000 accept L/C

MOQ Flexibility: Typically 5–10 pcs, mixed batches at no extra charge

Inspection: SGS/BV approx. USD 450; free factory audit for orders ≥ 50 pcs

Urgent Shipments: Air freight 3–5 days to Europe/US, fees based on weight/volume

Cost Comparison: Despite a 2–3× higher material price, titanium's 10-year life-cycle cost can be up to 30% lower than stainless steel or copper-nickel alloys

Get a quote now: Upload your drawings or material list now to receive a free, itemized quotation PDF within 24 hours.