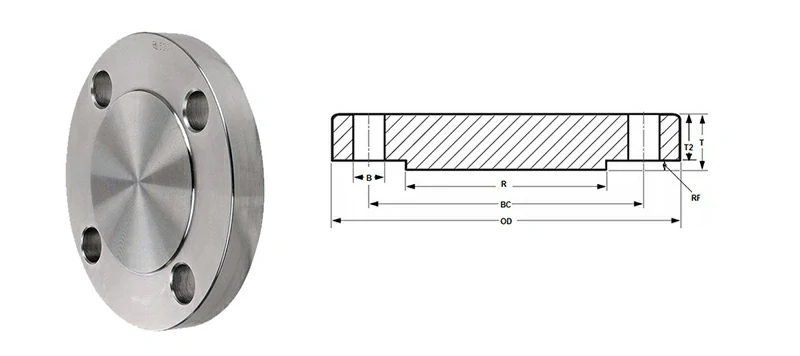

Titanium Blind Flanges

Updated : Jun. 23, 2025A titanium blind flange is a solid flange with no center hole. It is mainly used to seal pipe ends or inspection ports and prevent fluid leakage. Its corrosion resistance and strength make it ideal for petrochemical, offshore, nuclear, and shipbuilding industries.

Why Choose Our Titanium Blind Flanges?

- We offer various sealing faces like RF, RTJ, and FF. RTJ is especially recommended for high-pressure and highly corrosive conditions.

- Materials comply with ASTM B381 / ASME SB381. GR1, GR2, and GR5 are available. For harsh chloride corrosion (like marine environments), GR7 is strongly recommended.

- Flange nominal dimensions and bolt hole patterns comply with ASME B16.5 / B16.47 requirements.

- Supports ASME B16.5 pressure ratings from Class 150 to Class 2500.

- We stock standard sizes, offer low minimum order quantities, and respond quickly to urgent needs.

- Designs follow global standards, ensuring long-term leak-free performance and reduced maintenance costs.

Our Supplied Flange Standards and Sizes

| Specification | Nom. Pipe Size | Class/PN | Sealing Face Type | Alloys |

|---|---|---|---|---|

| ASME B16.5 (USA) | ½" - 24" | Class 150 - 2500 | RF, RTJ, FF | GR1, GR2, GR5 |

| ASME B16.47 A/B (USA) | 26" - 60" | Class 150 - 900 | RF, RTJ | GR5, GR7 |

| EN 1092-1 (Europe) | DN10 - DN600 | PN10 - PN40 | RF, FF | GR2, GR7 |

| GB/T 9119 (China) | DN10 - DN600 | PN2.5 - PN40 | RF, FF | GR2, GR5 |

| JIS B2220 (Japan) | 10A - 600A | 5K - 63K | FF | GR2, GR5 |

| UNI 2276/6092 (Italy) | DN10 - DN600 | 6Bar - 40Bar | RF, FF | GR2, GR5 |

| BS 4504 (UK) | DN15 - DN600 | PN6 - PN40 | RF, FF | GR2, GR5 |

*When ordering, please specify the nominal pipe size (in inches) and pressure rating.

Customer Projects

High-Temp Steam Seal

GR5 flange used in a Chinese refinery during 2021 for sealing high-pressure steam lines. Used ASME B16.5 Class 900 RTJ flange, size NPS 10".

Marine Salt Environment

In 2020, a Malaysian offshore platform used GR7 EN 1092-1 DN200 PN40 RF flanges to seal seawater cooling pipes. GR7 resisted chloride corrosion well.

Nuclear High-Pressure System

In 2019, a 28" PN160 GR5 blind flange was used in the Volga nuclear plant. It showed no leakage after 18 months of high-pressure operation.

Backflow Protection in LNG Vessel

In 2022, a Korean LNG ship used a JIS 20K FF GR2 blind flange (250A) near a seawater exchanger. It performed well in humid and salty conditions.

Working Pressure Reference Table (psi)

| Temp (°C) | Allowable Working Pressure (psi) | ||||||

|---|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 | |

| 650 | - | 4.7 | 6.3 | 9.5 | 14.2 | 23.6 | 39.4 |

| -29 ~ 38 | 20 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

| 575 | - | 9.4 | 12.6 | 18.9 | 28.3 | 47.2 | 78.6 |

| 100 | 17.7 | 51.5 | 68.7 | 103 | 154.6 | 257.6 | 429.4 |

| 538 | 1.4 | 16.5 | 22.1 | 33.1 | 49.6 | 82.7 | 137.9 |

| 200 | 13.8 | 48.6 | 64.8 | 97.2 | 145.8 | 243.4 | 405.4 |

| 475 | 3.7 | 31.7 | 42.3 | 63.4 | 95.1 | 158.2 | 263.9 |

| 300 | 10.2 | 42.9 | 57 | 85.7 | 128.6 | 214.4 | 357.1 |

| 350 | 8.4 | 40.3 | 53.6 | 80.4 | 120.7 | 201.1 | 335.3 |

| 375 | 7.4 | 38.9 | 51.6 | 77.6 | 116.5 | 194.1 | 323.2 |

| 425 | 5.5 | 35.2 | 46.5 | 70 | 105.1 | 175.1 | 291.6 |

| 450 | 4.6 | 33.7 | 45.1 | 67.7 | 101.4 | 169 | 281.8 |

| 400 | 6.5 | 36.5 | 48.9 | 73.3 | 109.8 | 183.1 | 304.9 |

| 325 | 9.3 | 41.4 | 55 | 82.6 | 124 | 206.6 | 344.3 |

| 500 | 2.8 | 28.2 | 37.6 | 56.5 | 84.7 | 140.9 | 235 |

| 250 | 12.1 | 46.3 | 61.7 | 92.7 | 139 | 231.8 | 386.2 |

| 550 | - | 13.9 | 18.6 | 27.9 | 41.8 | 69.7 | 116.2 |

| 150 | 15.8 | 50.3 | 66.8 | 100.3 | 150.6 | 250.8 | 418.2 |

| 600 | - | 6.6 | 8.9 | 13.3 | 19.9 | 33.2 | 55.3 |

| 50 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

| 625 | - | 5.1 | 6.8 | 10.3 | 15.4 | 25.7 | 42.8 |

Purchase & Service Guarantee

- Material Test Report (MTR)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Eddy Current Testing (ET)

- MOQ: 1 piece. Stock available for small orders.

- Delivery: 3 days for stock, 15–25 days for custom orders.

- Packaging: Air or sea freight, safe and secure.

- After-sales: Tech support, quality guarantee, easy returns.

Integrated Titanium Flange Production System

In addition to Titanium Blind Flanges, Chalco Titanium supplies a comprehensive range of titanium flange types to meet various piping system demands. Our offerings include Titanium Weld Neck Flange, Titanium Threaded Flange, Titanium Lap Joint Flange, Titanium Slip On Flange, and the complete Titanium Flanges product family.

With advanced forging equipment, CNC machining centers, and strict quality assurance procedures, we provide reliable flange solutions with full certification and global export experience. Contact us to discuss your technical requirements and receive a customized quotation.

FAQ

Q1: What's the difference between a blind flange and a threaded cap?

A blind flange has no hole and seals the pipe. A threaded cap usually has holes and mounts accessories.

Q2: How much pressure can a titanium blind flange handle?

Our products cover Class 150 to Class 2500. Actual pressure depends on pipe design.

Q3: How do I choose the right titanium alloy?

Use GR7 for seawater or strong corrosives. GR1 or GR2 suits general use. GR5 is for high strength needs.

Need Titanium Blind Flanges?

- Chat on WhatsApp: +86-173-44894490

- Email Us: contact@chalcoaluminum.com

Get Your Price in Minutes!