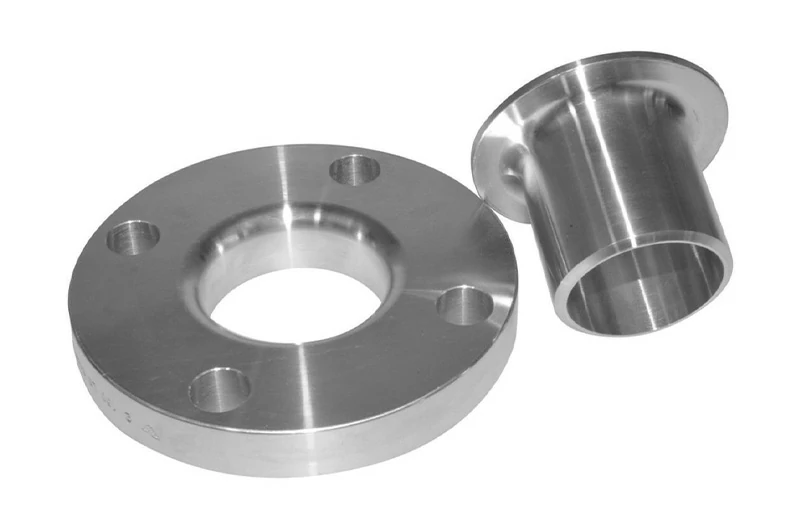

Titanium Lap Joint Flange

Updated : Aug. 12, 20253-Line Value Snapshot

Rotatable Ring – perfect bolt alignment, single-shot gasket seating

Replace Stub Only – corrosion isolated; ring reusable under proper protection

20–35 % Cost Cut – media touches titanium only; ring in stainless or Ti¹

Quick Specs

| Item | Range / Note |

|---|---|

| Nominal Size (NPS) | ½″–12″ (DN15–DN300) |

| Pressure Class | 150 / 300 in stock; 400 / 600 on request (verify via ASME B16.5 App A) |

| Stub End Grade | Gr 2 stock ½″–8″; >8″ and Gr 7 MTO 4–6 wk |

| Ring Material | 304 / 316L / 2205 / Gr 2 / Gr 5 (use 316L/2205 for wet chlorine & offshore) |

| Stub Style | MSS SP-43 short / ASME B16.9 long |

| Tests & Docs | 100 % PMI, UT/PT; EN 10204 3.1 MTC |

| Lead Time | Gr 2 ≤ 7 d; custom 15 d |

Why Titanium Lap-Joint vs. Others

| Feature | Lap-Joint Ti | Slip-On Ti | Weld-Neck Ti |

|---|---|---|---|

| Corrosion cost | ★★★★★ | ★★★★ | ★★★ |

| Maintenance ease | ★★★★★ | ★★★ | ★★ |

| Lined pipe friendly | Excellent | Fair | Poor |

| High-pressure duty | Medium (≤ 600) | Medium | High |

| Up-front cost | Low-Medium | Medium | High |

Application Highlights

| Sector / Media | Recommended Set-up | Typical Benefit |

|---|---|---|

| Wet chlorine | Gr 7 stub + 316L/2205 ring | Ring immune; swap stubs every 3 yrs |

| Seawater/OFFSHORE | Gr 2 stub + 316L ring | 25–30 % cheaper than all-Ti flanges |

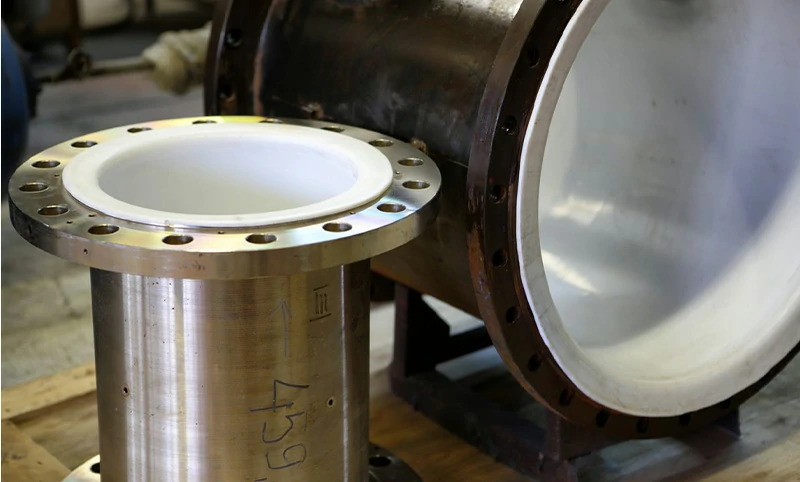

| PTFE-lined pipe | Gr 2 stub + 304 ring | Media touches only PTFE & Ti; zero ion pickup |

Quality & Assembly Notes

Welding – full-penetration GTAW of stub to pipe (ASME B31.3)

Ring Protection – select stainless or Ti for corrosive atmospheres; coat threads with anti-gall paste for reuse

Bolt Torque – follow ASME PCC-1 or gasket vendor tables; four-pass star pattern and re-torque after 24 h

Full Range Titanium Flange Manufacturing Capability

Chalco Titanium manufactures not only Titanium Lap Joint Flange products, but also a complete portfolio of titanium flange types to support various piping configurations. We supply Titanium Weld Neck Flange, Titanium Threaded Flange, Titanium Slip On Flange, Titanium Blind Flanges, and other Titanium Flanges for corrosion-resistant and high-performance systems.

Our in-house forging and CNC machining facilities ensure tight tolerances, stable sealing performance, and reliable structural strength. We support customized dimensions, international standards, and project-based production for global industrial applications.

FAQ

Q: Is Class 600 feasible for lap joints?

A: Yes, provided ring section modulus meets ASME B16.5 App A and B31.3 stress limits.

Q: How many times can the ring be reused?

A: Multiple cycles under good corrosion protection and lubrication; actual count depends on bolt cycling and environment.