Titanium Coupling

Updated : Jul. 16, 2025Titanium coupling offers the ideal combination of corrosion resistance and strength-to-weight ratio for demanding piping systems.

We offer titanium full and half couplings designed for demanding environments, ensuring reliable, leak-free sealing, with custom sizes available to meet your specific application requirements.

Titanium coupling specifications

- ASME B16.11

- ASTM B348

- MSS SP-79 / 95 / 83 / 97

- BS 3799

We also provide third-party inspection reports from SGS, TÜV, and full mill test certificates (MTC) upon request to ensure reliable product quality.

Popular titanium coupling products

- Size range: 1/8" NB to 4" NB

- Material grades: Gr 1, Gr 2, Gr 5, Gr 7

- Pressure ratings: 2000 LBS, 3000 LBS, 4500 LBS, 6000 LBS

- Connection types: socket weld, threaded, half coupling

- Manufacturing methods: forged titanium coupling, machined from bar stock

- Suitable media: air, oil, brine, water, natural gas, and corrosive chemical fluids

Socket weld titanium coupling

Ideal for high-pressure sealed pipelines. Delivers strong welds and leak-free performance—perfect for chemical and oil & gas systems.

Contact us now

Threaded titanium coupling

Easy to install and suited for small-diameter piping. Commonly used in water, gas, and general fluid systems.

Contact us nowWe also supply half couplings with threaded or welded ends. One side connects to pipes or equipment. Widely used in chemical, petroleum, and marine industries.

Have custom size, alloy, or inspection needs? Contact us anytime for a quote and technical support. Quick Quote

Equivalent standards for titanium coupling

| Alloy Grade | ASTM | ISO | DIN | JIS | GB/T |

|---|---|---|---|---|---|

| Gr 1 | Grade 1 | R50250 | 3.7025 | TP270 | TA1 |

| Gr 2 | Grade 2 | R50400 | 3.7035 | TP340 | TA2 |

| Gr 5 | Ti-6Al-4V | R56400 | 3.7165 | Ti-6Al-4V | TC4 |

| Gr 7 | Ti-0.2Pd | R52400 | 3.7235 | TP340Pd | TA9 |

- Grade 1 (TA1 / TP270): the softest commercially pure titanium, excellent for corrosion-resistant but low-stress applications.

- Grade 2 (TA2 / TP340): the most widely used titanium grade, balancing strength, corrosion resistance, and weldability.

- Grade 5 (Ti-6Al-4V / TC4): high-strength titanium alloy for demanding structural or high-pressure systems.

- Grade 7 (TA9 / TP340Pd): palladium-alloyed titanium offering superior resistance to chlorides and acids.

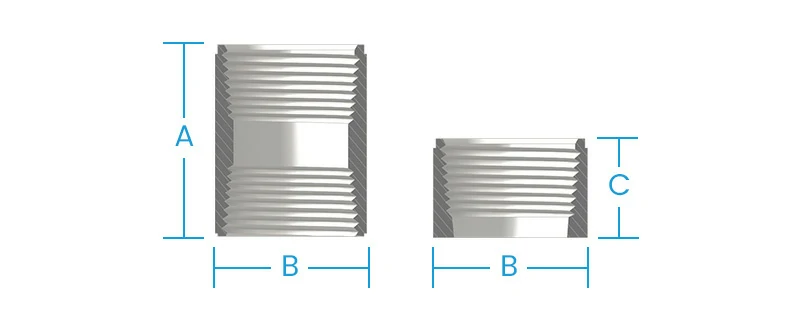

Titanium coupling dimensions

This table lists common Nominal Pipe Sizes (NPS) along with corresponding outside diameters and standard dimensions for full couplings and half couplings—designed to help you select the right titanium coupling.

| Size | B | A | C |

|---|---|---|---|

| Nom. Pipe Size | Common Diameter | Full Coupling | Half Coupling |

| 1/8" | 3/4 | 1-1/4 | 5/8 |

| 1/4" | 3/4 | 1-3/8 | 11/16 |

| 3/8" | 7/8 | 1-1/2 | 3/4 |

| 1/2" | 1-1/8 | 1-7/8 | 15/16 |

| 3/4" | 1-3/8 | 2 | 1 |

| 1" | 1-3/4 | 2-3/8 | 1-3/16 |

| 1-1/4" | 2-1/4 | 2-5/8 | 1-5/16 |

| 1-1/2" | 2-1/2 | 3-1/8 | 1-9/16 |

| 2" | 3 | 3-3/8 | 1-11/16 |

Please refer to the inventory table below for Chalco's available stock.

| Specification | NPS | Class | Type | In Stock |

|---|---|---|---|---|

| 1/4" 3000# FULL COUPLING GR 2 | 1/4" | 3000# | FULL COUPLING | 63 |

| 3/8" 3000# FULL COUPLING GR 2 | 3/8" | 3000# | FULL COUPLING | 25 |

| 1/2" 3000# FULL COUPLING GR 2 | 1/2" | 3000# | FULL COUPLING | 56 |

| 3/4" 3000# FULL COUPLING GR 2 | 3/4" | 3000# | FULL COUPLING | 45 |

| 1" 3000# FULL COUPLING GR 2 | 1" | 3000# | FULL COUPLING | 31 |

| 1-1/4" 3000# FULL COUPLING GR2 | 1-1/4" | 3000# | FULL COUPLING | 55 |

| 1-1/2" 3000# FULL COUPLING GR 2 | 1-1/2" | 3000# | FULL COUPLING | 84 |

| 2" 3000# FULL COUPLING GR 2 | 2" | 3000# | FULL COUPLING | 14 |

| 3" 3000# FULL COUPLING GR2 | 3" | 3000# | FULL COUPLING | 25 |

| 1/4" 3000# HALF COUPLING GR2 | 1/4" | 3000# | HALF COUPLING | 63 |

| 3/8" 3000# HALF COUPLING GR2 | 3/8" | 3000# | HALF COUPLING | 14 |

| 1/2" 3000# HALF COUPLING GR2 | 1/2" | 3000# | HALF COUPLING | 25 |

| 3/4" 3000# HALF COUPLING GR 2 | 3/4" | 3000# | HALF COUPLING | 34 |

| 1" 3000# HALF COUPLING GR 2 | 1" | 3000# | HALF COUPLING | 85 |

| 1-1/4" 3000# HALF COUPLING GR2 | 1-1/4" | 3000# | HALF COUPLING | 25 |

| 1-1/2" 3000# HALF COUPLING GR 2 | 1-1/2" | 3000# | HALF COUPLING | 42 |

| 2" 3000# HALF COUPLING GR 2 | 2" | 3000# | HALF COUPLING | 23 |

| 1" 3000# SKTWELD FULL COUPLING GR2 | 1" | 3000# | SKTWELD FULL COUPLING | 85 |

In addition to standard items, we offer custom titanium couplings based on drawings, pressure ratings, special lengths, or thread standards to meet non-standard project needs.

For demanding conditions—such as high temperatures, corrosive media, or special connections—we can assist with selection and provide mill test certificates (MTC).

Contact our engineering team now for a detailed quote, material report, or samples. Quick Quote

Titanium coupling applications

Our titanium couplings deliver excellent sealing performance, making them ideal for harsh industrial and marine environments. They offer superior corrosion resistance in saltwater and coastal climates.

Common pipeline applications include:

- Shipbuilding, submarines, and offshore pipeline systems

- Air delivery and exhaust systems

- Water and gas supply lines

- Cooling water return lines in power plants

- Chemical and petrochemical fluid transport

- Oil and gas systems with sulfur or high-chloride media

- Automotive fuel, oil, and coolant lines

- High-strength aerospace connections

- Pharmaceutical and high-purity water systems

Titanium coupling case study

Chalco supplied titanium couplings to a major refinery in the Middle East, supporting a system upgrade for enhanced corrosion resistance.

In 2024, the refinery faced frequent failures of stainless steel fittings due to high temperatures and chloride-rich conditions during equipment retrofitting.

After extensive technical evaluations and vendor comparisons, the client selected Chalco's Gr.2 threaded titanium couplings—fully compliant with ASTM B381 and ASME B16.11, and certified by NACE MR0175 with TÜV third-party inspection.

Post-delivery, the pipeline system ran smoothly. The customer praised the couplings for their sealing performance, corrosion resistance, and extended service life. Maintenance frequency dropped significantly, and operating costs were greatly reduced.

Titanium coupling vs. stainless steel

In harsh industrial environments—such as systems with chlorides, acids, or high temperature and pressure—choosing the right pipe coupling is critical.

Titanium couplings are increasingly replacing stainless steel and carbon steel fittings due to their superior corrosion resistance and strength.

Compared to 316L stainless steel, titanium couplings offer much longer service life in chloride-rich or seawater conditions, preventing pitting and stress corrosion cracking.

For instance, 316L often fails within one year under high-chloride exposure, while Gr.2 and Gr.7 titanium couplings can operate reliably for over five years—cutting maintenance and replacement costs.

Titanium couplings also deliver high strength. Gr.2 yields over 300 MPa, while high-strength grades like Gr.5 reach up to 800 MPa—far exceeding most stainless steel alloys.

Their lightweight design reduces overall pipeline load and improves system efficiency.

Titanium coupling cost and value

In real-world use, titanium couplings last 3 to 5 times longer than standard fittings—minimizing replacements and preventing costly shutdowns caused by leaks.

While the upfront cost is higher than stainless steel, titanium couplings offer unmatched stability and lifespan in corrosive environments—far beyond 316L and similar alloys.

From a full life cycle perspective, titanium couplings are a smarter, more cost-effective investment.

To lower the purchasing barrier, we support small-batch orders and phased delivery by project stage.

Popular sizes are in stock for fast shipping, and we offer flexible lead times, custom dimensions, and full technical support. Quick Quote

Titanium forged fittings packaging and global delivery

- Shock-proof bubble wrap, sealed bags, and anti-corrosion paper ensure safe transport.

- Reinforced wooden cases or export-grade pallets used based on weight and volume.

- Supports DHL, FedEx, UPS, and TNT for small-batch or urgent international orders.

- Flexible logistics options: sea freight, air freight, and rail transport available.

- Each product comes with labels, inspection certificates, material reports, and export documents.

- Custom project codes and QR labels available for easy job site tracking and identification.

- Global shipping covers the Middle East, Europe, North America, Southeast Asia, and more.

Related products for titanium coupling

We also supply matching titanium elbows, tees, reducers, and flanges to support fully integrated piping systems.

Titanium Crosses

Frequently asked questions (FAQ)

What's the difference between Grade 2 and Grade 5 titanium?

Grade 2 is commercially pure titanium with excellent corrosion resistance and weldability. It's ideal for chemical and marine applications.

Grade 5 (also known as Ti-6Al-4V) is a high-strength titanium alloy containing aluminum and vanadium—used in aerospace and motorsport systems requiring high pressure and strength.

What is the purpose of a titanium coupling?

Titanium couplings are used to connect two sections of pipe, ensuring sealing and flow continuity.

They're widely used in seawater desalination, chemical processing, oil & gas, power plants, and pharmaceutical systems where corrosion and strength are critical.

What is a female coupling?

A female coupling typically refers to a fitting with internal threads. In titanium couplings, the internal thread version is called a female end—used for systems that require frequent disassembly and reassembly.

Can titanium be forged?

Absolutely. Titanium is a forgeable metal. Titanium couplings are often made through hot forging, in compliance with standards like ASTM B381, ensuring high strength, compact structure, and excellent corrosion resistance.