Titanium Transition Reducer

Updated : Jun. 26, 2025Titanium reducer is a key titanium pipe fitting used to connect pipes of different diameters. Titanium is 40% lighter than steel, offering excellent corrosion resistance, a high strength-to-weight ratio, and outstanding durability.

We stock titanium concentric reducers and titanium eccentric reducers from 1/2 inch to 8 inches, available in S10 and S40 schedules, compliant with ASTM B363 and ASME B16.9 standards.

Titanium reducer standards

Our titanium concentric and eccentric reducers meet the following international manufacturing and dimensional standards.

- ASTM B363

- ASME B16.9 / ANSI B16.9

- MSS-SP-43 Type A/B

- JIS B2312 / JIS B2313

- EN 10204 3.1

- PED compliant

- SGS inspection report available

Our facility is certified to ISO 9001, GJB 9001, ISO 14001, ISO 45001, and IATF 16949, with a Special Equipment License for pressure components and marine-grade Lloyd's Register certification.

Titanium reducer alloys

Titanium reducers are available in GR1, GR2, GR7, and GR12, with other grades customizable to meet specific strength and corrosion resistance requirements.

-

Grade 2 (CP-Ti) Titanium Reducer

Workhorse CP‑Ti offering balanced strength and weldability for general industry.

-

Grade 7 (Ti-Pd) Titanium Reducer

Ti‑Pd alloy built for extreme acid‑ and chloride‑rich environments.

-

Grade 12 (Ti-Ni-Mo) Titanium Reducer

Ni‑Mo‑titanium reducer delivering higher strength and heat resistance in mildly reducing media.

Titanium reducer products

Titanium reducers are available in two types: concentric reducers and eccentric reducers, with sizes ranging from NPS 1/4 inch to 48 inches.

Reducers 4 inches and smaller are formed from seamless titanium pipes. Larger sizes are fabricated from titanium plates and welded, with all welds 100% X-ray inspected for quality assurance.Quick Quote

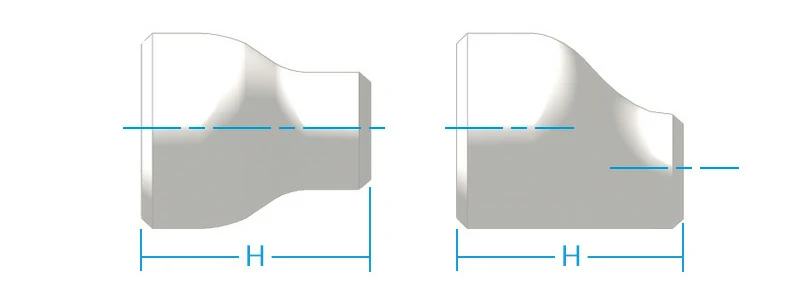

Titanium concentric reducer

Smooth flow transitions for vertical pipes, titanium concentric reducer for balanced pressure.

Contact us now

Titanium eccentric reducer

Offset titanium eccentric reducer prevents fluid or gas buildup in horizontal pipelines.

Contact us nowTitanium reducer cone for automotive exhaust

Titanium reducer cones are ideal for automotive exhaust systems, offering lightweight, heat-resistant transitions between different pipe sizes.

Contact us now

These are our most popular and best-selling titanium reducers, frequently chosen by customers worldwide.

1.5" (38mm) - 2" (51mm) Titanium Concentric Size Reducer

2" (51mm) - 2.5" (63mm) Titanium Concentric Size Reducer

2" (51mm) - 3" (76mm) Titanium Concentric Size Reducer

1.5" (38mm) - 3" (76mm) Titanium Concentric Size Reducer

3" (76mm) - 4" (101mm) Titanium Concentric Size Reducer

4" (101mm) - 5" (127mm) Titanium Concentric Size Reducer

1.5" to 2" Titanium Transition Reducer 1.188" OAL - .039"/1mm

2" to 3" Titanium Transition Reducer 2.375" OAL - .039"/1mm

Cone/Megaphone 2 3/8” IN 3.5” OUT 13.8” OAL 1mm/.039"

Titanium reducer stock sizes

Chalco offers a wide range of titanium reducers in stock, with standard diameters from 1/2 inch to 8 inches.

You can find the right size and type to match your project requirements. Explore our inventory and contact us for custom specifications. Quick Quote

Concentric reducer

Concentric titanium reducers are available in sizes ranging from 1.000" (25.4 mm) x 0.500" (12.7 mm) up to 8.000" (203.2 mm) x 6.000" (152.4 mm).

Contact us now

| Product Type | Larger OD (inch) | Smaller OD (Inch) | Schedule |

|---|---|---|---|

| Titanium Concentric Reducer | 4.000" | 2.000" | S10 |

| Titanium Concentric Reducer | 4.000" | 2.000" | S40 |

| Titanium Concentric Reducer | 4.000" | 3.000" | S10 |

| Titanium Concentric Reducer | 6.000" | 3.000" | S10 |

| Titanium Concentric Reducer | 6.000" | 4.000" | S10 |

| Titanium Concentric Reducer | 6.000" | 4.000" | S40 |

| Titanium Concentric Reducer | 8.000" | 4.000" | S10 |

| Titanium Concentric Reducer | 8.000" | 6.000" | S10 |

| Titanium Concentric Reducer | 1.000" | 0.500" | S10 |

| Titanium Concentric Reducer | 1.000" | 0.750" | S10 |

| Titanium Concentric Reducer | 1.500" | 0.750" | S10 |

| Titanium Concentric Reducer | 1.500" | 1.000" | S10 |

| Titanium Concentric Reducer | 1.500" | 1.000" | S40 |

| Titanium Concentric Reducer | 2.000" | 1.000" | S40 |

Eccentric reducer

Eccentric titanium reducers are available in sizes ranging from 2.000" (50.8 mm) x 1.000" (25.4 mm) up to 8.000" (203.2 mm) x 6.000" (152.4 mm).

Contact us now

| Product Type | Larger OD (inch) | Smaller OD (Inch) | Schedule |

|---|---|---|---|

| Titanium Eccentric Reducer | 2.000" | 1.000" | S10 |

| Titanium Eccentric Reducer | 2.000" | 1.500" | S10 |

| Titanium Eccentric Reducer | 3.000" | 2.000" | S10 |

| Titanium Eccentric Reducer | 4.000" | 3.000" | S10 |

| Titanium Eccentric Reducer | 6.000" | 3.000" | S10 |

| Titanium Eccentric Reducer | 6.000" | 4.000" | S10 |

| Titanium Eccentric Reducer | 6.000" | 4.000" | S40 |

| Titanium Eccentric Reducer | 8.000" | 6.000" | S10 |

Titanium reducer sizes for exhaust systems

Chalco's titanium reducer cones are perfect for users needing to transition exhaust pipe sizes or create custom muffler sections and end caps for tailored exhaust systems.

Contact us now

These transition reducer cones save you the time and hassle of flaring pipes yourself, offering smoother transitions and a cleaner surface finish.

| Transition Size | Wall Thickness(in) | Wall Thickness(mm) | Length |

|---|---|---|---|

| 2" to 3" | .039"/0.047" | 1mm/1.2mm | 2 3/8" Long |

| 3" to 4" | .039"/0.047" | 1mm/1.2mm | 2 3/8" Long |

| 4" to 5" | .039"/0.047" | 1mm/1.2mm | 2 1/2" Long |

| 1.5" to 2" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 2" to 2.5" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 2.5" to 3" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 3" to 3.5" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 3.5" to 4" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 4" to 4.5" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| 4.5" to 5" | .039"/0.047" | 1mm/1.2mm | 1 3/16" Long |

| Megaphone 2 3/8" to 3.5" | .039"/0.047" | 1mm/1.2mm | 13.8" Long |

Can't find the size you need? Contact us for custom fabrication. Quick Quote

Click below to view all available sizes in the list below.

Advantages of titanium reducer

- Titanium reducers are significantly lighter than steel, reducing overall system weight.

- They offer outstanding corrosion resistance in acids, alkalis, seawater, and harsh industrial environments.

- Titanium reducers maintain structural stability at temperatures exceeding 600 °C.

- With high tensile strength and fatigue resistance, they perform well under pressure.

- Their long service life minimizes replacement frequency and reduces maintenance costs.

- The heat-induced color gradient (burnt blue) adds a premium visual finish for automotive use.

Applications of titanium reducer

Titanium reducers are used in high-temperature settings where strength and low weight matter. They provide smooth diameter transitions and enhance piping flexibility.

Automotive / Motorcycle Exhaust Systems

Widely used in the North American aftermarket, titanium reducers connect exhaust sections of different diameters, reducing weight and improving heat resistance.

Contact us now

Power Generation

Used in high-temperature water and steam pipelines, such as cooling systems in nuclear and thermal power plants, where pressure and heat resistance are critical.

Contact us nowChemical & Petrochemical Processing

Ideal for transferring highly corrosive media like chlor-alkali, fine chemicals, and acid-alkali pipelines with smooth transitions.

Contact us now

Oil & Gas

Extensively used in wellhead piping and offshore drilling platforms, offering enhanced durability and safety in corrosive environments.

Contact us nowIn addition to the main industries, titanium reducers are also widely used for flow velocity control, pump inlet optimization, and instrumentation connections.

Real case highlights

A Southeast Asian paper mill integrated our Grade 12 titanium eccentric reducers into its acid circulation lines in the bleaching section.

The system required resistance to chloride-rich environments and a precise offset connection to prevent air pocket accumulation.

After 2+ years of operation, the reducers remain free of corrosion or deformation, outperforming previously used stainless steel fittings.

Titanium reducer manufacturing process

To ensure dimensional accuracy, structural strength, and inventory compatibility, our titanium reducers are made using two different methods based on size.

≤ 4 inches — seamless forming

Reducers 4 inches and smaller are hot-formed from Grade 2 seamless titanium pipes. They feature a weld-free structure with high strength and smooth transitions.

≥ 4 inches — titanium plate rolling + laser welding

Larger reducers are CNC-rolled from Grade 2 titanium plates and joined using precision laser welding. All welds undergo 100% X-ray inspection to ensure sealing and weld integrity.

All titanium reducers are fully compatible with standard fittings—no additional machining required.

Welding and compatibility

Our titanium reducers offer excellent weldability and seamless integration with Chalco-brand titanium elbows, V-band clamps, flanges, coil tubes, flexible corrugated hoses, pipe caps, and blind flanges.

For optimal welding results, we recommend using Chalco titanium welding wire, matched to the same alloy grade. This ensures clean welds with no cracks or inclusions. Quick Quote

Titanium elbow

Throttle body flange

Titanium tee

Titanium stub end

30-degree mandrel titanium elbow

Titanium welding wire

Why choose us

- We supply high-purity GR1, GR2, GR7, and GR12 titanium, with 100% traceable raw materials.

- All dimensions strictly comply with ASTM B363 and ASME B16.9 standards.

- Custom options available: DN15–DN600+, concentric/eccentric, seamless/welded structures.

- Our factory is located in Baoji, China’s "Titanium Valley,” offering direct-from-source pricing with strong cost advantages.

- Standard sizes are in stock for fast global delivery and door-to-door service.

- Our technical team supports you through material selection, customs clearance, technical coordination, and after-sales service.

Quality inspection and testing methods

- GDMS or XRF is used to verify alloy purity and grade accuracy.

- Tensile strength, yield strength, and elongation are tested to assess mechanical performance.

- Thickness, outer diameter, and total length are measured to ensure dimensional tolerances.

- Visual and ultrasonic inspections detect surface defects such as scratches, cracks, or inclusions.

- Hardness testing confirms material uniformity and mechanical stability.

Packaging and delivery of titanium reducer

- Each reducer is wrapped with protective film or foam to avoid scratches and impact during transit.

- Small orders are packed in reinforced cartons; bulk shipments use fumigation-free wooden crates with shock-absorbing lining.

- Each package is labeled with size, grade, heat number, and quantity for easy tracking and inventory.

- Worldwide shipping by air, sea, or express (DHL/FedEx) is available, with full export documentation support.

Titanium reducer FAQs

What are the disadvantages of titanium exhaust systems?

The main drawback is cost—titanium exhaust systems are usually more expensive than stainless steel. They may also produce popping sounds and a humming noise due to their thin walls.

Are titanium exhaust pipes street legal?

Long-term testing of motorcycles equipped with titanium exhaust systems showed emissions exceeding current California Air Resources Board (CARB) limits. As a result, BMW Motorrad USA stopped selling these systems in the U.S. market.

Can you MIG weld a titanium exhaust pipe?

Yes, titanium can be MIG welded, but it's rarely done. MIG welding tends to generate excessive heat and spatter, which can contaminate the weld area and reduce quality. TIG welding is preferred for its cleaner, more controlled results.

Complete size range of titanium reducers

| Nom. Pipe Size | Outside Diameter at Bevel (Large End) | Outside Diameter at Bevel (Small End) | End-to-End (H) |

|---|---|---|---|

| 3/4 x 1/2 | 1.05 | 0.84 | 1.50 |

| 3/4 x 3/8 | 1.05 | 0.68 | 1.50 |

| 1 x 3/4 | 1.32 | 1.05 | 2.00 |

| 1 x 1/2 | 1.32 | 0.84 | 2.00 |

| 1-1/4 x 1 | 1.66 | 1.32 | 2.00 |

| 1-1/4 x 3/4 | 1.66 | 1.05 | 2.00 |

| 1-1/4 x 1/2 | 1.66 | 0.84 | 2.00 |

| 1-1/2 x 1-1/4 | 1.90 | 1.66 | 2.50 |

| 1-1/2 x 1 | 1.90 | 1.32 | 2.50 |

| 1-1/2 x 3/4 | 1.90 | 1.05 | 2.50 |

| 1-1/2 x 1/2 | 1.90 | 0.84 | 2.50 |

| 2 x 1-1/2 | 2.38 | 1.90 | 3.00 |

| 2 x 1-1/4 | 2.38 | 1.66 | 3.00 |

| 2 x 1 | 2.38 | 1.32 | 3.00 |

| 2 x 3/4 | 2.38 | 1.05 | 3.00 |

| 2-1/2 x 2 | 2.88 | 2.38 | 3.50 |

| 2-1/2 x 1-1/2 | 2.88 | 1.90 | 3.50 |

| 2-1/2 x 1-1/4 | 2.88 | 1.66 | 3.50 |

| 2-1/2 x 1 | 2.88 | 1.32 | 3.50 |

| 3 x 2-1/2 | 3.50 | 2.88 | 3.50 |

| 3 x 2 | 3.50 | 2.38 | 3.50 |

| 3 x 1-1/2 | 3.50 | 1.90 | 3.50 |

| 3 x 1-1/4 | 3.50 | 1.66 | 3.50 |

| 3-1/2 x 3 | 4.00 | 3.50 | 4.00 |

| 3-1/2 x 2-1/2 | 4.00 | 2.88 | 4.00 |

| 3-1/2 x 2 | 4.00 | 2.38 | 4.00 |

| 3-1/2 x 1-1/2 | 4.00 | 1.90 | 4.00 |

| 3-1/2 x 1-1/4 | 4.00 | 1.66 | 4.00 |

| 4 x 3-1/2 | 4.50 | 4.00 | 4.00 |

| 4 x 3 | 4.50 | 3.50 | 4.00 |

| 4 x 2-1/2 | 4.50 | 2.88 | 4.00 |

| 4 x 2 | 4.50 | 2.38 | 4.00 |

| 4 x 1-1/2 | 4.50 | 1.90 | 4.00 |

| 5 x 4 | 5.56 | 4.50 | 5.00 |

| 5 x 3-1/2 | 5.56 | 4.00 | 5.00 |

| 5 x 3 | 5.56 | 3.50 | 5.00 |

| 5 x 2-1/2 | 5.56 | 2.88 | 5.00 |

| 5 x 2 | 5.56 | 2.38 | 5.00 |

| 6 x 5 | 6.62 | 5.56 | 5.50 |

| 6 x 4 | 6.62 | 4.50 | 5.50 |

| 6 x 3-1/2 | 6.62 | 4.00 | 5.50 |

| 6 x 3 | 6.62 | 3.50 | 5.50 |

| 6 x 2-1/2 | 6.62 | 2.88 | 5.50 |

| 8 x 6 | 8.62 | 6.62 | 6.00 |

| 8 x 5 | 8.62 | 5.56 | 6.00 |

| 8 x 4 | 8.62 | 4.50 | 6.00 |

| 8 x 3-1/2 | 8.62 | 4.00 | 6.00 |

| 10 x 8 | 10.75 | 8.62 | 7.00 |

| 10 x 6 | 10.75 | 6.62 | 7.00 |

| 10 x 5 | 10.75 | 5.56 | 7.00 |

| 10 x 4 | 10.75 | 4.50 | 7.00 |

| 12 x 10 | 12.75 | 10.75 | 8.00 |

| 12 x 8 | 12.75 | 8.62 | 8.00 |

| 12 x 6 | 12.75 | 6.62 | 8.00 |

| 12 x 5 | 12.75 | 5.56 | 8.00 |

| 14 x 12 | 14.00 | 12.75 | 13.00 |

| 14 x 10 | 14.00 | 10.75 | 13.00 |

| 14 x 8 | 14.00 | 8.62 | 13.00 |

| 14 x 6 | 14.00 | 6.62 | 13.00 |

| 16 x 14 | 16.00 | 14.00 | 14.00 |

| 16 x 12 | 16.00 | 12.75 | 14.00 |

| 16 x 10 | 16.00 | 10.75 | 14.00 |

| 16 x 8 | 16.00 | 8.62 | 14.00 |

| 18 x 16 | 18.00 | 16.00 | 15.00 |

| 18 x 14 | 18.00 | 14.00 | 15.00 |

| 18 x 12 | 18.00 | 12.75 | 15.00 |

| 18 x 10 | 18.00 | 10.75 | 15.00 |

Contact us for samples, latest pricing, or order assistance—our team will respond promptly.