Titanium Pipe Tee

Updated : Jun. 26, 2025Titanium Tee – seamless or welded, Sch 10S/40S, 0.75–8 in NPS.

Up to 60 % lighter than steel yet far more corrosion‑resistant, these tees excel in chemical‑processing and diverse industrial lines.

Titanium tee specifications

- ASTM B363 (WPT-2W, WPT-2S)

- ASTM B862

- ASME SB-363

- ASME B16.9

- ASME B16.11

- MSS SP-43

- EN 10204 Type 3.1 / 3.1 (10-2004)

Our production and service centers are certified to ISO 9001, AS9100, and AS9120 (UK and Germany), fully comply with PED requirements, provide EN 10204 3.1 traceability, and meet all international export and project documentation standards.

Titanium tee alloys

-

Grade 1 (UNS R50250)

Soft and ductile titanium tee, ideal for low-pressure, highly corrosion-sensitive environments.

-

Grade 2 (UNS R50400)

The most widely used titanium tee grade, offering a balance of strength, weldability, and corrosion resistance.

-

Grade 3 (UNS R50550)

Higher strength titanium tee suitable for medium-pressure piping systems with moderate corrosion.

-

Grade 7 (UNS R52400)

Palladium-alloyed titanium tee with excellent acid and chloride resistance.

-

Grade 12 (UNS R53400)

Strong, weldable tee with top crevice corrosion resistance for marine use.

-

Grade 5 (UNS R56400)

High-strength tee for aerospace and high-pressure industrial systems.

Popular titanium tee products

We offer a full range of titanium tees, including equal tees, reducing tees, long branch tees, short outlet tees, and butt-weld tees.

All models are available in diameters from 1/2 inch to 8 inches. Quick Quote

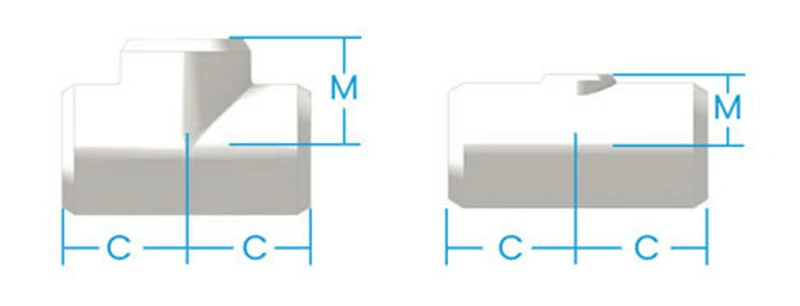

Straight Tee / Equal Tee

Standard titanium tee with three equal-diameter outlets, ideal for branching uniform pipe sizes in industrial systems.

Contact us now

Reduced Tee / Reducing Tee

Titanium tee with a smaller branch outlet, designed for connecting pipelines of different diameters while saving space and cost.

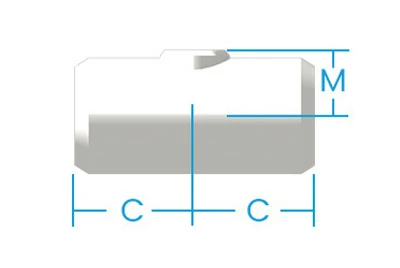

Contact us nowLong Outlet Tee

Custom titanium tee with an extended branch length for easier welding, insulation, or instrumentation access in complex layouts.

Contact us now

Short Outlet Tee

Compact titanium tee with a shortened branch, perfect for tight installation spaces and equipment with limited clearance.

Contact us nowSocket Weld Tee

Precision-machined titanium tee with socket ends, commonly used for small-diameter, high-purity or high-pressure systems.

Contact us now

Threaded Tee

Titanium tee with threaded ends, allowing for quick, weld-free installation in maintenance-friendly or removable systems.

Contact us nowSeamless Tee

High-strength, leak-proof titanium tee formed from seamless tube, recommended for critical pressure or purity applications.

Contact us now

Welded Tee

Cost-effective welded titanium tee fabricated to standard dimensions, suitable for large-diameter or non-pressure systems.

Contact us nowTitanium tee stock sizes

Titanium tee fittings are available in sizes ranging from 0.750 inch (19.05 mm) to 8.000 inches (203.2 mm).

You can browse our stock to find the tee that fits your project needs. For custom sizes, please submit a quote request. Quick Quote

Straight tee dimensions

Long branch (LB) and short outlet (SO) refer to titanium tees with extended or shortened branch lengths, designed to accommodate specific space, welding, or flow configuration needs.

| Nominal Size (in) | Dim C (in) | Dim M (in) | Sch 10 Weight (lbs) | Sch 40 Weight (lbs) |

|---|---|---|---|---|

| 3/4 (SO) | 1.12 | 0.65 | 0.50 | |

| 3/4 (LB) | 1.12 | 1.12 | 0.30 | 0.50 |

| 1 (SO) | 1.50 | 0.79 | 0.25 | 0.50 |

| 1 (LB) | 1.50 | 1.50 | 0.50 | 1.00 |

| 1-1/2 (SO) | 2.25 | 1.08 | 1.00 | 2.00 |

| 1-1/2 (LB) | 2.25 | 2.25 | 1.15 | 2.50 |

| 2 (SO) | 2.50 | 1.31 | 1.20 | 2.50 |

| 2 (LB) | 2.50 | 2.50 | 1.60 | 3.00 |

| 3 (SO) | 3.38 | 1.88 | 1.50 | 2.60 |

| 3 (LB) | 3.38 | 3.38 | 4.00 | 8.00 |

| 4 (SO) | 4.12 | 2.38 | 2.10 | 3.80 |

| 4 (LB) | 4.12 | 4.12 | 5.50 | 0 |

| 6 (SO) | 5.62 | 3.44 | 4.60 | 8.75 |

Reducing tee dimensions

Reducing Tee

Reducing tee connects different pipe sizes with a smaller branch outlet for compact flow transitions.

Contact us now

| Nominal Size (in) | Dim C (in) | Dim M (in) | Sch 10 Weight (lbs) | Sch 40 Weight (lbs) |

|---|---|---|---|---|

| 1 x 1 x 1/2 | 1.50 | 0.72 | 0.2 | 0.4 |

| 1 x 1 x 3/4 | 1.50 | 0.72 | 0.2 | 0.4 |

| 1 1/2 x 1-1/2 x 1/2 | 2.25 | 1.08 | 0.5 | 0.65 |

| 1-1/2 x 1-1/2 x 3/4 | 2.25 | 1.08 | 0.5 | 0.65 |

| 1-1/2 x 1-1/2 x 1 | 2.25 | 1.08 | 0.5 | 0.65 |

| 2 x 2 x 3/4 | 2.50 | 1.32 | 0.7 | 1 |

| 2 x 2 x 1 | 2.50 | 1.25 | 0.7 | 1 |

| 2 x 2 x 1-1/2 | 2.50 | 1.08 | 0.7 | 1 |

| 3 x 3 x 1-1/2 | 3.38 | 1.88 | 1.5 | 2.7 |

| 3 x 3 x 2 | 3.38 | 1.88 | 1.5 | 2.7 |

| 4 x 4 x 2 | 4.12 | 2.38 | 2.3 | 4.5 |

| 4 x 4 x 3 | 4.12 | 2.38 | 2.3 | 4.5 |

| 6 x 6 x 3 | 5.62 | 3.45 | 5.5 | |

| 6 x 6 x 4 | 5.62 | 3.45 | 5.5 |

If you can't find the size you need, feel free to contact us for custom fabrication. Quick Quote

You can also click to view all available sizes.

Titanium tee precision tolerance guaranteed – ASME B16.9

We manufacture titanium tees to ASME B16.9 standards with strict dimensional tolerances for a precise and reliable fit.

| Nominal Pipe Size (in) | Outside Dia at Bevel (D) | Inside Dia at End | Center to End (C / M) | Wall Thk (t) |

|---|---|---|---|---|

| 1/2 to 2.1/2 | +1.6 -0.8 | +0.8 | +2 | ≥ 87.5% of nominal wall thickness |

| 3 to 3.1/2 | +1.6 | +1.6 | +2 | ≥ 87.5% of nominal wall thickness |

| 4 | +1.6 | +1.6 | +2 | ≥ 87.5% of nominal wall thickness |

| 5 to 8 | +2.4 -1.6 | +1.6 | +2 | ≥ 87.5% of nominal wall thickness |

| 10 to 18 | +4 -3.2 | +3.2 | +2 | ≥ 87.5% of nominal wall thickness |

| 20 to 24 | +6.4 -4.8 | +4.8 | +2 | ≥ 87.5% of nominal wall thickness |

| 26 to 30 | +6.4 -4.8 | +6.4 -4.8 | +3 | ≥ 87.5% of nominal wall thickness |

| 32 to 48 | +6.4 -4.8 | +6.4 -4.8 | +5 | ≥ 87.5% of nominal wall thickness |

Advantages of titanium tee

- Exceptional corrosion resistance resists acids, chlorides, and seawater in harsh environments.

- Lightweight with high strength reduces system weight without sacrificing durability.

- Long service life thanks to a stable oxide layer that minimizes maintenance.

- High temperature and pressure tolerance ensures reliable performance in demanding conditions.

- Excellent weldability makes installation easy, especially with Grade 2 and Grade 12.

- Purity make it suitable for pharmaceutical and clean applications.

- Compliance with ASTM B363 and ASME B16.9 ensures global compatibility and quality assurance.

Applications of titanium tee

Titanium tees are precisely machined with minimal tolerances, providing excellent corrosion resistance and a secure seal when merging two pipelines into one.

Unlike other materials that corrode in highly abrasive chemical environments, titanium maintains optimal performance and durability.

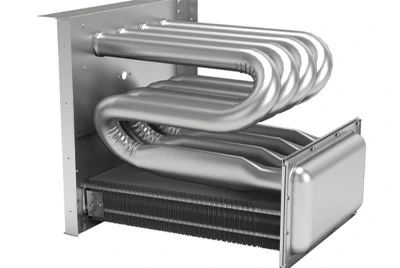

Heat exchangers, condensers, and evaporators

Suitable for shell-and-tube and plate-type units, where corrosion-free operation is critical.

Contact us now

HVAC and industrial cooling systems

Used in large-scale climate control infrastructure for reliable performance.

Contact us nowOil and gas transmission pipelines

Ideal for offshore drilling platforms, refineries, and sour gas systems requiring resistance to chlorides and hydrogen sulfide.

Contact us now

Pharmaceutical industry

Ensures cleanliness and corrosion resistance in high-purity process piping.

Contact us nowFood processing equipment

Non-toxic and resistant to cleaning chemicals, perfect for hygienic piping systems.

Contact us now

Titanium tee quality assurance

- All titanium tees are manufactured in strict accordance with ASTM B363 and ASME B16.9 standards, ensuring dimensional accuracy and structural integrity.

- Full-process quality control is implemented from raw material sourcing to final product delivery.

- Each product undergoes 100% visual and dimensional inspection before shipment. Nondestructive testing (e.g., ultrasonic or X-ray) is available for critical applications.

- Every batch comes with a Material Test Report (MTR), detailing chemical composition and mechanical properties to ensure traceability and consistency.

- Each titanium tee is clearly marked with alloy grade, size, and applicable standard for easy identification and tracking.

- Our manufacturing facilities are ISO 9001 certified, guaranteeing consistent and reliable product quality.

Matching titanium components available

Chalco is a leading manufacturer and supplier of titanium fittings, offering a wide range of sizes, grades, and specifications.

We also provide a complete lineup of titanium components—including tees, crosses, elbows, stub ends, flanges, caps, and reducers—to meet all your piping system requirements.

Titanium Cross

Titanium Elbow

Titanium Stub Ends

Titanium Flange

Titanium Caps

Titanium Reducer

Titanium tee installation – by connection type

Titanium tees are available in butt weld, socket weld, and threaded connection types, each designed to meet specific installation requirements.

Butt Weld Tee

Align the beveled ends and perform TIG welding for a strong, leak-free permanent connection.

Socket weld tee (for small diameter options)

The pipe is inserted into the socket, tack welded in place, and then fully welded around the joint—ideal for small-diameter systems.

Threaded tee (easy to assemble)

Apply sealant to the threads, hand-tighten the connection, then secure with a wrench—no welding required.

Frequently asked questions about titanium pipe tees

How much does a titanium pipe tee cost?

The price of a titanium tee varies based on grade, size, and quantity. Grade 2 titanium tees are the most cost-effective option for standard applications. Contact us for a quick quote.

How to choose a reliable titanium tee supplier?

Look for manufacturers certified with ISO or AS9100, compliant with ASTM B363 and ASME B16.9, and experienced in global exports. Chalco meets all of these criteria.

What are the types of tee fittings?

Common types include equal tees, reducing tees, long branch tees, short outlet tees, butt weld tees, socket weld tees, and threaded tees.

What's the difference between a tee and a Y fitting?

A tee has a 90° outlet, while a Y fitting branches or merges at a 45° angle, offering smoother directional flow transitions.

How do you determine the size of a tee fitting?

Start with the largest connection size (e.g., A = 1-1/2"), followed by the second run size (B = 1/2"), then the branch size (C = 1-1/4").

What's the difference between a threaded tee and a flanged tee?

Flanged tees offer higher strength and easier maintenance for high-pressure systems, while threaded tees are quicker to install and better suited for low-pressure use.

Can a slip-on flange be welded to a tee?

Yes, a slip-on flange can be welded to a butt weld or socket weld titanium tee to create a flange-to-flange connection.

More titanium tee sizes

We offer titanium tees in a wide range of sizes to match your pipeline specifications. Standard sizes are available as per ASME B16.9 and ASTM B363.

| Nominal Pipe Size | Outside diameterat bevel (mm) | Center-to-End (mm) Run C | Center-to-End (mm) Outlet M |

|---|---|---|---|

| 1/2″ | 21.3 | 25 | 25 |

| 3/4″ | 26.7 | 29 | 29 |

| 1″ | 33.4 | 38 | 38 |

| 1 1/4″ | 42.2 | 48 | 48 |

| 1 1/2″ | 48.3 | 57 | 57 |

| 2″ | 60.3 | 64 | 64 |

| 2 1/2″ | 73.0 | 76 | 76 |

| 3″ | 88.9 | 86 | 86 |

| 3 1/2″ | 101.6 | 95 | 95 |

| 4″ | 114.3 | 105 | 105 |

| 5″ | 141.3 | 124 | 124 |

| 6″ | 168.3 | 143 | 143 |

| 8″ | 219.1 | 178 | 178 |

| 10″ | 273.0 | 216 | 216 |

| 12″ | 323.8 | 254 | 254 |

| 14″ | 355.6 | 279 | 279 |

| 16″ | 406.4 | 305 | 305 |

| 18″ | 457.0 | 343 | 343 |

| 20″ | 508.0 | 381 | 381 |

| 22″ | 559.0 | 419 | 419 |

| 24″ | 610.0 | 432 | 432 |

Custom sizes, branch dimensions, or special configurations—such as short outlets or long branches—can be made according to your drawings or project requirements. Quick Quote