Titanium Wood Screws

Titanium wood screws are designed for decks, pools, docks, yachts, and all outdoor wooden structures. Made from Gr2/Gr5 titanium, they are lightweight, strong, salt-spray and chemical resistant, and non-magnetic for long-term stability.

With a Torx drive and Type 17 cutting tip, they drive smoothly into hardwood and treated lumber. They reduce slipping, prevent cracking, and keep a clean appearance over time.

Specifications of titanium wood screws

- DIN 571

- DIN 7997

- ISO 7049

- ISO 7050(DIN 7982)

- ISO 7051

- ISO 1478

- ASME/ANSI B18.6.1

We supply EN 10204 3.1 material certificates and RoHS/REACH compliance documents with every order, and can provide ASTM B117 salt spray, tensile, hardness, or dimensional test reports upon request.

Why choose titanium wood screws

- Resistant to salt spray and chlorides, they stay rust-free and stain-free in coastal, poolside, or chemical areas.

- Strong yet lightweight, perfect for boats, decks, and boardwalks where weight matters.

- Non-magnetic, safe for instruments and electrical environments with less interference.

- Torx drive with optimized self-tapping tip for fast entry into hardwood and treated lumber, with less slipping.

- Available in polished natural finish, anodized black/blue/gold/rainbow, or DLC for lasting outdoor beauty.

- Lower repair and replacement needs, offering better overall cost performance than 304/316 stainless steel.

- Gr2 focuses on corrosion resistance and formability, while Gr5 (Ti-6Al-4V) delivers high strength and load capacity.

- Customizable in head type, drive, length, and color, with samples available for secure testing.

Titanium wood screws product and sizes

Titanium wood screws are lightweight yet strong fasteners made from Gr2/Gr5 titanium, offering long-lasting corrosion resistance for decks, docks, yachts and outdoor wood structures.

Contact us now

- Diameter (metric/inch): M3–M8 (common M4/M5/M6/M8; ≈ #8 / #10 / 1/4″)

- Self-tapping (ST) equivalents: ST3.5 / ST3.9 / ST4.2 / ST4.8 / ST5.5 / ST6.3 (≈ M3.5 / M4 / M4.2 / M4.8 / M5.5 / M6)

- Length: 20–150 mm in stock, with custom lengths available.

For larger sizes such as M10 and above, heavy-duty lag screws or bolts are often preferred. We can supply them together with titanium wood screws, making it easier for you to complete one purchase.

Head type options

2024 aluminum plate

2024 aluminum plate

2024 aluminum plate

| Head type | Application | Drive | Tip |

|---|---|---|---|

| Countersunk / flat | Decks, outdoor exposed installs | Torx T20/T25/T30 (preferred) / Phillips / hex socket / external hex | Cutting tip (hardwood/treated wood) / drill tip (composite areas) |

| Pan head | Hardware, visible fittings | Torx / Phillips / hex socket | Cutting tip / drill tip |

| Hex / flange head | Load-bearing joints | External hex | Cutting tip |

In-stock selection

| Diameter | Typical length (stock) | Head type | Drive | Finish |

|---|---|---|---|---|

| M4 (≈ #8) | 25 / 30 / 40 / 50 / 60 mm | Countersunk / pan head | Torx T20 | Natural / black anodized |

| M5 (≈ #10) | 30 / 40 / 50 / 60 / 80 mm | Countersunk / pan head | Torx T25 | Natural / black / blue anodized |

| M6 (≈ 1/4″) | 40 / 50 / 60 / 80 / 100 mm | Countersunk / hex flange | Torx T30 / external hex | Natural / black anodized / DLC |

| M8 | 60 / 80 / 100 / 120 / 150 mm | Hex flange (load-bearing) | External hex | Natural / black anodized |

All titanium wood screws come with EN 10204 3.1 and RoHS/REACH certificates. Optional ASTM B117 salt spray, pull-out, hardness, and dimensional reports are available.

Provide your application details, and we will send pilot hole and torque recommendations, along with lead time, within 24 hours.

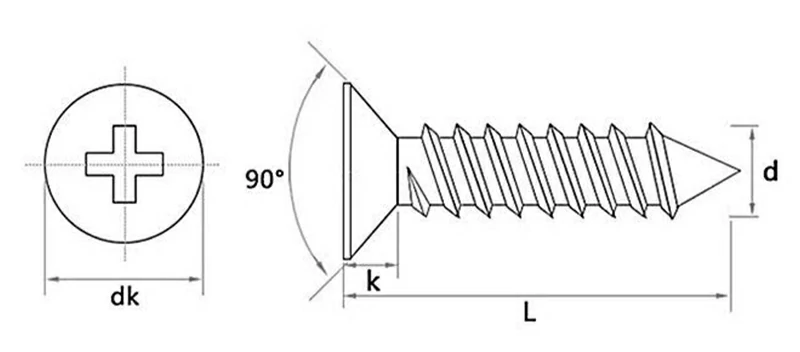

Metric countersunk reference dimensions (90°)

Unit: mm

| D nominal diameter | M3 | M3.5 | M4 | M4.2 | M5 | M6 | M8 |

|---|---|---|---|---|---|---|---|

| dk head diameter | 5.3 | 6.5 | 7.2 | 7.6 | 8.7 | 11.8 | 14.1 |

| K head height | 2.0 | 2.5 | 2.6 | 2.7 | 3.0 | 4.75 | 5.2 |

We also provide complete tables for other head geometries, such as pan head, flange head, and external hex. Just share the diameter and head type you need, and we can send the data quickly.

Applications of titanium wood screws

Coastal homes

Decks, railings, stairs, and wooden fences

Long-term resistance to salt spray and chlorides, no stains or discoloration.

Contact us now

Recommended: Countersunk / flat head with Torx (T20/T25/T30), Type 17 cutting tip. Use Gr2 for corrosion resistance; choose Gr5 for load-bearing parts.

Boats and docks

Yacht decks, cabin woodwork, dock fenders, and piers

High strength-to-weight ratio for significant weight savings and extended maintenance cycles.

Contact us now

Recommended: Countersunk, flange, or hex head; Torx or external hex. Use Gr5 for critical joints; black anodized or DLC finish for durability and appearance.

Pools, spas, and water parks

Platforms, steps, and fences.

Resistant to chlorinated water, stays rust-free, and looks clean in exposed areas.

Contact us now

Recommended: Countersunk head with Torx, Type 17 cutting tip; black anodized or natural finish.

Chemical and research facilities

Wooden platforms, walkways, and equipment bases.

Non-magnetic, corrosion-resistant, and suitable for sensitive environments.

Contact us now

Recommended: Countersunk or flange head; Gr2 for corrosion resistance, Gr5 for higher strength. Certificates EN 10204 3.1 and optional salt spray / pull-out reports available.

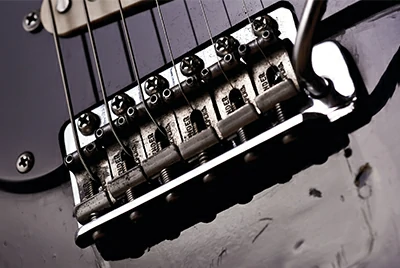

Musical instruments and audio woodwork (small fastenings)

Small titanium wood screws are used for pickguards, backplates, pickups, and bridge mounts, combining secure fastening with corrosion resistance.

Titanium posts and studs can also be custom-made.

Contact us now

Recommended: Small countersunk or pan head with Torx or Phillips drive. Finishes in natural or black anodized.

Models and RC (boats, cars, planes, helicopters)

Ultra-light, durable, and corrosion-resistant, they reduce maintenance for outdoor use.

Contact us now

Recommended: 3×18 mm small countersunk Torx screws, available in sets for higher efficiency.

Our promise of quality and service

- Over 10 years of titanium fastener manufacturing experience, factory-direct with OEM/ODM customization.

- Made from Gr2/Gr5 titanium with strict process control, each order includes material certificates.

- EN 10204 3.1 reports available for every batch, with optional salt spray, pull-out, and hardness tests.

- Certified to ISO 9001, compliant with RoHS/REACH, and third-party inspections available.

- Samples available for testing, with low MOQ for trial orders and fast delivery for large volumes.

- Multiple payment options, engineer support for installation and selection, and full after-sales traceability.

Installation guide

To ensure titanium wood screws hold firmly in wood and deliver long-term durability, follow these tips during installation:

- Drill a pilot hole about 60–80% of the screw’s outer diameter. For countersunk or flat heads, add a recess so the head sits flush.

- Use Torx T20/T25/T30 drivers for tighter grip, reducing slipping and surface damage.

- Apply a light coat of PTFE or wax on the threads, and avoid direct contact with dissimilar metals to prevent galling or galvanic corrosion.

- Embed screws to a depth at least 2–3 times the wood thickness to ensure fastening strength.

Maintenance tip: Inspect exposed screws every quarter. Reapply wax coating if needed to extend service life.

Shipping and payment terms

Bulk orders are usually shipped worldwide by sea, packed in containers for port pickup and customs clearance.

For urgent or small orders, air freight is available for faster delivery, ideal for samples or time-sensitive projects.

Flexible trade terms such as DDP, FOB, and CIF are supported, with extensive customs experience in North America and Europe.

We accept T/T (30% deposit + 70% before shipment), L/C for large orders, and PayPal for small payments upon request.

Packaging includes inner bags, desiccants, moisture-proof film, and outer cartons, reinforced with corner protectors for safe long-distance transport.

Labels can be supplied in neutral packaging or with custom logos to meet your branding needs.

One-stop titanium fastening solutions

Choose us not only for a full range of titanium screws, but also for complete one-stop delivery.

Titanium wood screws FAQ

What are the disadvantages of titanium screws?

More expensive and harder to machine than steel.

Is titanium good for screws?

Yes, they are strong, light, and highly corrosion-resistant.

How long do titanium screws last?

10+ years in coastal or pool environments.

Do titanium wood screws need pre-drilling?

For hardwood, pre-drilling and countersinking are recommended. Softwood can be driven directly, but pre-drilling gives more stability.

Gr2 vs Gr5: how to choose?

Gr2 offers excellent corrosion resistance. Gr5 provides higher strength, ideal for load-bearing or larger sizes.

Why choose titanium over 316 stainless steel?

Titanium delivers longer service life, less maintenance, and lower total cost over time.