Corrosion-Resistant Titanium Screws

Our screws are made from aerospace-grade titanium. They’re up to 400% stronger and 50% lighter than steel, engineered for high-performance applications.

Available in M3–M15 with all head types.

Titanium screws selection guide

Titanium alloy screws are about 40% lighter than carbon steel and stainless steel, yet deliver a much higher strength-to-weight ratio.

They are widely used in aerospace, medical, automotive, marine, and precision manufacturing industries. We offer a full range of standard and custom options, including:

- Alloys: Grade 2, Grade 5

- Thread types: UNC, UNF, UNJ, UNR, full metric (M) series; available in rolled or cut threads

- Diameter range: #00 – 4 in / M1.2 – M48

- Grade material availability: Grade 2 (M2–M8 / #2–3/8"), Grade 5 (M2–M16 / #4–½"), with support for Gr7 and Gr23

- Popular inch sizes: 2-56, 4-40, 6-32, 8-32, 10-32, ¼-20

- Popular metric sizes: M3, M4, M5, M6, lengths from 4.74 mm to 40 mm

- Standards compliance: ANSI / ASME, DIN / ISO, NACE MR0175, ASTM, MIL, DFARS

- Customization options: Non-standard designs, production per drawing, laser marking, anodized surfaces, special packaging

Titanium socket head screws

-

Titanium cap head screws deliver tensile strength up to 895 MPa.

The hex socket design handles higher torque while weighing only 56% of steel.

They are ideal for robotics, drones, precision instruments, and high-end bicycles.

| Metric diameter | Recommended torque (N·m) | Imperial thread | Recommended torque (lbf·in) |

|---|---|---|---|

| M3 × 0.5 | 1.4 | #6-32 | 8 |

| M4 × 0.7 | 3.2 | #8-32 | 16 |

| M5 × 0.8 | 6.5 | #10-24 | 28 |

| M6 × 1.0 | 15 | ¼-20 | 75 |

| M8 × 1.25 | 32 | 5⁄16-18 | 160 |

| M10 × 1.5 | 50 | ⅜-16 | 260 |

Titanium flat head screws

-

Titanium flat head screws Featuring a 90° / 100° countersunk design with a smooth, flush head.

Made from Grade 2 or Grade 5 titanium for exceptional corrosion resistance, even in seawater environments.

Recommended for marine decks, chemical flanges, and carbon fiber skins.

| Metric diameter | Torque (N·m) | Imperial thread | Torque (lbf·in) |

|---|---|---|---|

| M3 | 1.2 | #4-40 | 6 |

| M4 | 2.8 | #6-32 | 8 |

| M5 | 5.6 | #8-32 | 16 |

| M6 | 12 | ¼-20 | 65 |

Titanium button head screws

-

Titanium button head screws Designed with a low-profile, rounded head for a sleek appearance. Available in nine anodized colors, with full bike kit shipping options.

Recommended for motorcycle fairings, mountain bikes, and aftermarket parts installation.

Optional services include custom anodized colors, full-vehicle torque stickers, and anti-loosening threadlock treatment.

| Metric diameter | Torque (N·m) | Imperial thread | Torque (lbf·in) |

|---|---|---|---|

| M4 | 2.5 | #8-32 | 14 |

| M5 | 5.0 | #10-24 | 24 |

| M6 | 11 | ¼-20 | 55 |

| M8 | 25 | 5⁄16-18 | 130 |

Titanium set screws

-

Titanium set screws Offered in cup point, cone point, and flat point styles for high hardness and excellent corrosion resistance. A TiN coating reduces slippage and surface wear.

Optional services include laser engraving, ultra-fine pitch threads, and batch-numbered bag packaging.

| Metric | Torque (N·m) | Imperial | Torque (lbf·in) |

|---|---|---|---|

| M3 | 1.0 | #4-40 | 5 |

| M4 | 2.5 | #6-32 | 9 |

| M5 | 5.0 | #8-32 | 16 |

| M6 | 10 | ¼-20 | 48 |

Titanium self tapping screws

-

Titanium self tapping screws Featuring AB/B thread design for high tapping efficiency while minimizing galvanic corrosion risk.

Optional services include insulating washers, anti-galvanic coatings, and hardened threads.

| Metric | Torque (N·m) | Imperial | Torque (lbf·in) |

|---|---|---|---|

| ST3.5 | 1.8 | #6 | 10 |

| ST4.2 | 3.8 | #8 | 18 |

| ST4.8 | 6.0 | #10 | 28 |

Titanium torx screws

-

Titanium torx screws The Torx drive increases torque capacity and reduces cam-out. Tamper-resistant Torx-Pin versions are available for enhanced security.

Can be supplied with matching installation tools.

| Metric | Torque (N·m) | Imperial | Torque (lbf·in) |

|---|---|---|---|

| M3 (T10) | 1.4 | #6-32 (T15) | 9 |

| M4 (T20) | 3.2 | #8-32 (T20) | 16 |

| M5 (T25) | 6.8 | #10-24 (T25) | 30 |

| M6 (T30) | 15 | ¼-20 (T30) | 75 |

Titanium wood screws

-

Titanium wood screws Designed with a deep thread for strong holding power and a thermal expansion coefficient matched to wood, reducing the risk of cracking.

Highly resistant to seawater corrosion.

Recommended for boat decks, wooden docks, and outdoor landscaping structures.

| Imperial (common) | Torque (lbf·in) | Metric equivalent | Torque (N·m) |

|---|---|---|---|

| #8 × 2″ | 20 | 4.2 mm × 50 mm | 2.3 |

| #10 × 2½″ | 30 | 4.8 mm × 60 mm | 3.4 |

| #12 × 3″ | 45 | 5.5 mm × 75 mm | 5.1 |

If you require non-stock sizes or special-grade titanium screws, we offer custom production with low minimum order quantities. Lead times start from as fast as 4 weeks—contact us today for a tailored solution and expedited scheduling. Quick Quote

Why choose titanium screws

- Aerospace-grade titanium alloy – about half the weight of steel at the same strength, creating lighter structures.

- Corrosion-free even after long-term exposure to seawater, acids, or alkalis.

- Rolled threads on all screws improve fatigue resistance by at least 30% compared to machined threads.

- Deep hex sockets make tool insertion easier for slip-free installation and removal.

- No fracture in low temperatures, with short-term heat resistance up to 480 °C.

- RoHS 3 compliant, non-toxic, and non-magnetic.

Applications and industry solutions

Aerospace titanium fasteners

Uses: structural joints, skin fastening, avionics brackets, and engine components.

- About 43% lighter than traditional A286 alloy, while meeting high-load and long fatigue-life requirements.

- Supports NAS / LN / MS cross-reference specifications, compliant with AS9100D aerospace quality management system.

Motorcycle titanium bolt kit

Recommended for: fairings, brake discs, swingarms, and engine covers.

- Lightweight with personalized anodizing in 9 colors and enhanced corrosion resistance.

- M6 screws tested to withstand 50 Nm torque.

- Reduces replacement time by about 15 minutes compared to steel bolts.

Bicycle titanium screws

Recommended for: seat clamps, headsets, brake calipers, bottle cages, and crankset locking.

- M5 × 20 mm and M6 × 20 mm, individually packed for compatibility with multiple models.

- Full titanium screw replacement solutions available, with M5 / M6 common sizes in stock and eye-catching rainbow anodizing.

Marine corrosion-resistant screws

Recommended for: seawater pumps, subsea cable clamps, hull accessories, and desalination system structures.

- Pitting rate in chloride-containing circulating seawater is < 0.005 mm/y.

- Optional insulating washers or surface coatings to prevent galvanic corrosion when in contact with stainless steel.

Vacuum-compatible titanium screws

Recommended for: semiconductor equipment, laser cavities, scientific vacuum experiment setups, and particle collider components.

- Cleanroom process ensures particle counts meet ISO Class 6 standards.

- MoS₂ coating reduces friction coefficient by 30%, ideal for oil-free high-vacuum assembly.

Surface treatments and value-added machining services

To meet diverse requirements for appearance, wear resistance, corrosion protection, and assembly performance, we offer a range of titanium screw surface treatments and personalized machining options.

Anodizing

Up to 9 colors available (including titanium rainbow, blue, gold, purple, etc.), with a coating thickness of around 10 µm—ideal for enhancing the look of racing, cycling, and consumer electronics products.

Hard anodizing up to 25 µm is available for friction-prone parts or outdoor exposure applications.

DLC / MoS₂ coatings (dry-film lubrication)

DLC black mirror-finish hard coating offers high hardness and superior wear resistance, commonly used in racing, aerospace, and medical fasteners.

MoS₂ coating reduces friction coefficient by about 30%, effectively preventing galling—ideal for oil-free vacuum environments or repeated screw assembly/disassembly.

5-axis CNC precision machining & laser marking

Precision finishing with ± 0.02 mm tolerance, supporting non-standard head shapes, special profiles, countersinks, vent holes, and other complex machining.

Batch numbers, customer codes, or brand logos can be laser-engraved on screw heads or packaging for traceability and inventory management.

All surface treatments can be provided with sample previews or test reports.

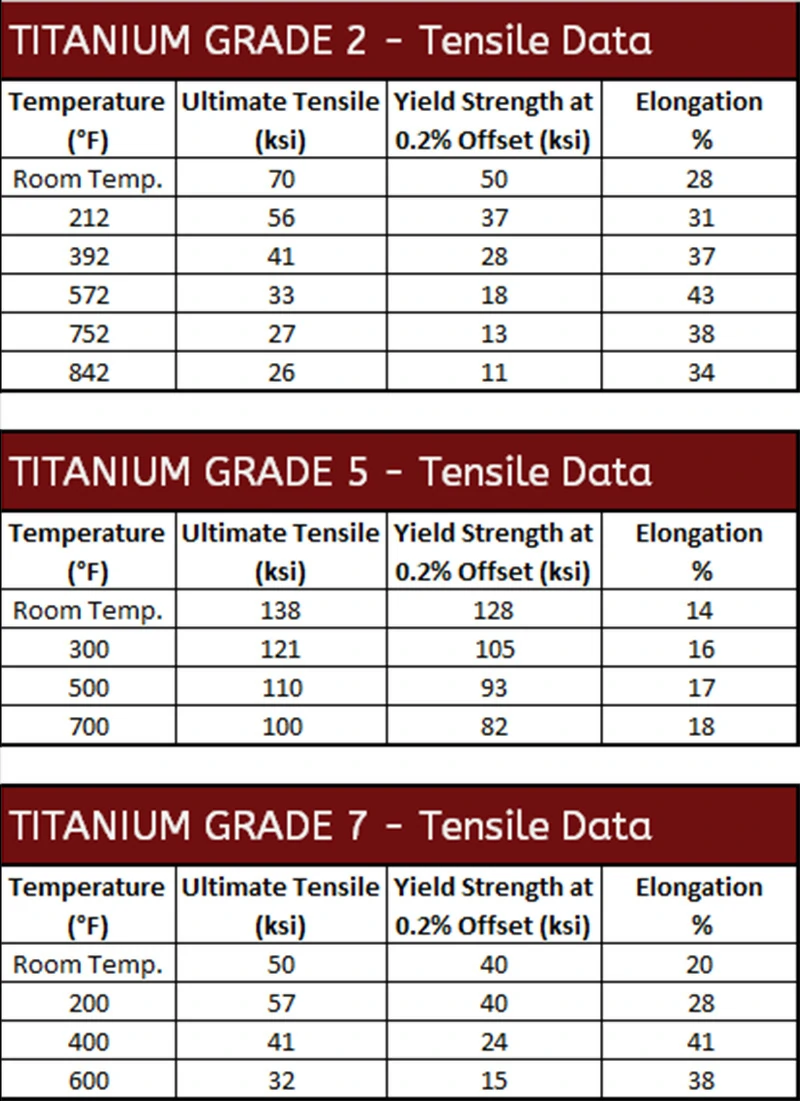

How strong are titanium screws?

Our titanium screws are primarily made from Grade 2, Grade 5, and Grade 7 materials. All have been extensively tested and proven to maintain stable mechanical performance across a wide range of temperatures.

- For high strength with low weight, Grade 5 is the perfect choice.

- For corrosion resistance and non-magnetic performance, Grade 2 is ideal.

- For the harshest environments such as chlorine exposure or seawater, choose Grade 7.

All our titanium screws come with ASTM material certificates, ensuring transparent data and full batch traceability—so you can buy and use with confidence.

Not sure which grade to choose? Send us a message with your application environment. We’ll recommend the right material for free and can even send samples for testing!

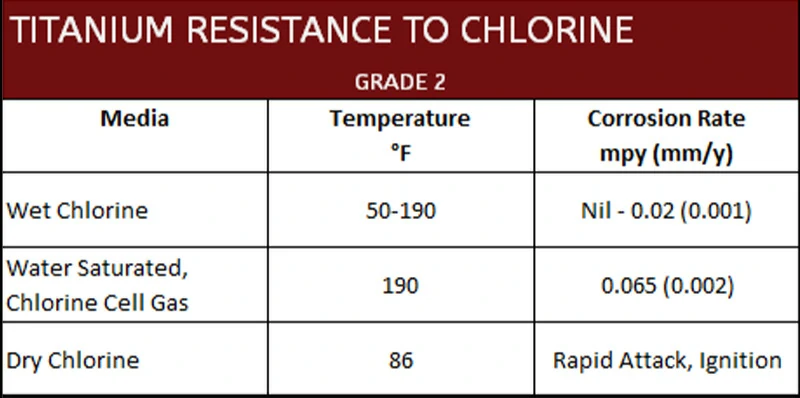

Titanium's resistance to chlorine corrosion

Titanium has exceptional resistance to chloride-induced corrosion. Even in environments containing sodium chloride (seawater), sodium hypochlorite (bleach), or chlorine gas, it can maintain a stable, rust-free surface over the long term.

This is because titanium naturally forms a dense, self-healing oxide film that protects against pitting and crevice corrosion caused by chloride ions.

Making procurement easier and more reliable

- China warehouse stock, with UPS / DHL delivery to over 80 countries and regions in 3–5 days.

- Supports prototype trials and low minimum order quantities for stress-free purchasing.

- Each product bag includes a unique QR code to instantly access chemical composition and batch information.

- Designed for vacuum and cleanroom applications, with residual oxygen/hydrocarbon content < 20 ppm.

- Engineering team offers support in EN / JP / ES / DE / Chinese, ensuring seamless service for global customers.

Related titanium screw products

In addition to a wide variety of titanium screws, we also stock the following titanium alloy fastener products—supporting complete set selection and consolidated shipment:

Titanium bolts

Titanium nuts

Titanium washers

Titanium threaded rods

Titanium rivets

Titanium threaded inserts

Popular sizes are kept in ample stock for immediate dispatch. While we list common models, our inventory updates daily—so if you require special sizes or configurations, feel free to contact us anytime for the latest stock and pricing!Quick Quote

Titanium screws FAQ

Is titanium good for screws?

Yes. Titanium is an excellent screw material, combining high strength, low weight, exceptional corrosion resistance, and non-magnetic properties.

What are the disadvantages of titanium screws?

Titanium screws are more expensive than steel and stainless steel, but they offer long-term value in terms of performance and lifespan.

Titanium is harder, has lower thermal conductivity, and is more difficult to machine, which increases production costs and slightly extends lead times.

Why are titanium screws so expensive?

Mainly because titanium is difficult to refine, challenging to machine (prone to cutting difficulties and high tool wear), and requires stricter quality control (such as vacuum cleaning, traceability, and precision control).

However, titanium screws can often be installed once and used for a lifetime, making them more cost-effective in the long run.

What is the lifespan of a titanium screw?

Under normal operating conditions, titanium screws can last over 10 years—and often much longer.

Are titanium screws safe for surgery?

Yes — titanium is biocompatible, non-magnetic, and widely used in bone and dental implants.

What’s the difference between titanium screws and stainless steel screws?

Titanium is lighter, more corrosion-resistant, and non-magnetic, while stainless steel is heavier and more cost-effective.

Can titanium screws be used for wood applications?

Yes — they resist rust, won’t crack wood, and are ideal for outdoor decks, docks, and boats.