Titanium Flat Bar

Titanium Flat Bar is widely used in aerospace structures, medical devices, offshore equipment, and other applications where strength, corrosion resistance, and weight are crucial. As a structural profile, it offers an excellent strength-to-weight ratio, dimensional stability, and long-term service reliability, making it a preferred high-performance material for engineers across a wide range of industries.

Chalco Titanium offers a comprehensive range of titanium alloy flat bars, including common grades such as Grade 2, Grade 5, and Grade 23. Cut to length, these bars meet standards such as ASTM B348, AMS 4928, and ISO 13485. Through multiple vacuum melting processes and precision machining, we ensure each flat bar possesses high cleanliness and consistency, making it suitable for our customers' demanding high-end manufacturing applications.

Why choose our titanium flat bar?

- The strength is as high as 950 MPa, but the weight is only half of steel, which is light and strong.

- Salt spray test for 500 hours without pitting, long-term resistance to seawater and corrosive environment

- Each product comes with a material number and test report, in line with international standards

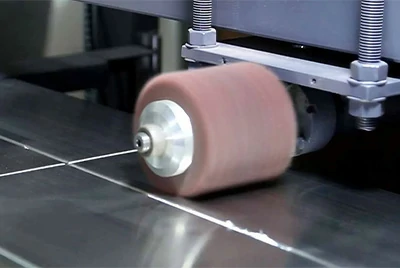

- Support water jet and saw cutting, cut to size according to demand, and ship within 48 hours at the fastest

- The factory has passed ISO 9001, AS9100, ISO 13485 and other system certifications, and the quality is guaranteed

Spot dimensions and tolerances

Chalco Titanium offers a wide range of titanium alloy flat bars, including Grade 2, Grade 5 (Ti-6Al-4V), and Grade 23 (ELI), in a comprehensive range of specifications, available in cut-to-width and cut-to-length sizes. Standard stock thicknesses range from 6–50 mm, and all materials comply with international standards such as ASTM B348, AMS 4928, and ISO 13485.

| Thickness (mm) | Width (mm) | Length ≤ (mm) | Sawing tolerance |

|---|---|---|---|

| 6 – 12 | 10 – 150 | 6 000 | +0 / − 0.40mm |

| 13 – 25 | 20 – 200 | 6 000 | +0 / − 0.30mm |

| 26 – 50 | 30 – 300 | 4 000 | +0 / − 0.25mm |

Click to view the stock breakdown for more information on sizes and stock status.

Titanium flat bar alloy selection recommendations

Choosing the right titanium alloy for each structural component's strength requirements, processing methods, and service environment is key to ensuring reliable performance and reasonable costs. Chalco Titanium offers a wide range of titanium alloy flat bars, covering aerospace, medical, offshore, and industrial applications. These bars support various post-processing methods, including sawing, waterjet, and CNC machining. The following are recommended alloys for your reference:

| Alloy grade | Main Features | Application Scenario | Selection Instructions |

|---|---|---|---|

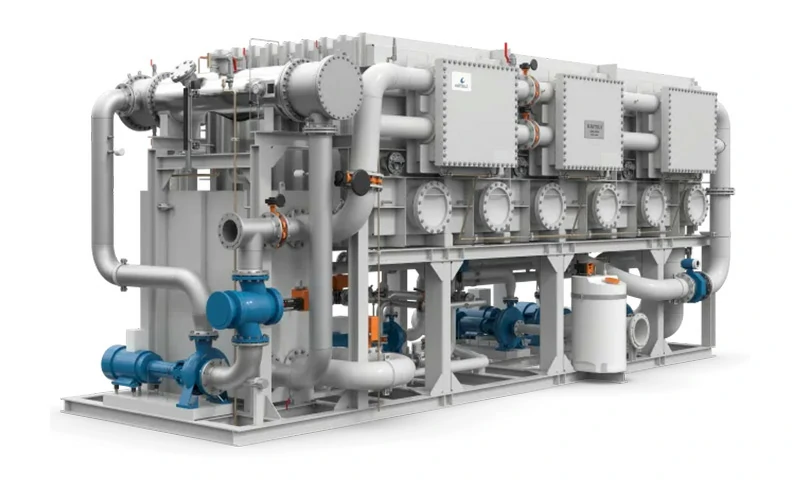

| Gr2 (commercially pure titanium) | Good formability, strong corrosion resistance, and weldability | Seawater desalination equipment, chemical heat exchangers, medical fixtures, shell structures | Cost-effective, suitable for structural profiles in light loads and corrosive environments |

| Gr5 (Ti-6Al-4V) | High strength, weldability, good heat resistance | Aviation structural parts, industrial pressure-bearing components, power system brackets, and processed parts substrates | The most commonly used structural grade titanium alloy, with a balance of strength and processability, and is widely used |

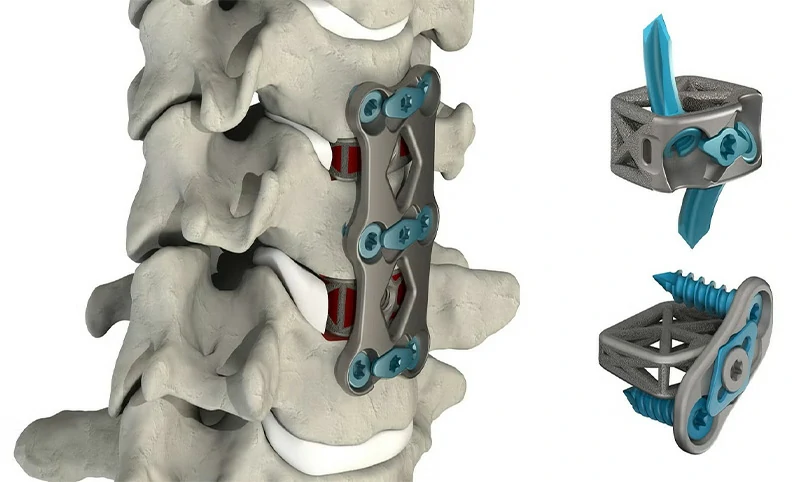

| Gr23 (Ti-6Al-4V ELI) | Low impurities, excellent biocompatibility, and better ductility | Medical implants, orthopedic fixation plates, surgical instruments, clean equipment parts | Meets ISO 13485 and ASTM F136 requirements, suitable for implantation and high-cleanliness scenarios |

| Gr9 (Ti-3Al-2.5V) | Medium strength, light weight, good cold working performance | Industrial support structures, thin-walled assemblies, chemical shells, small frame structures | The performance is between Gr2 and Gr5, suitable for light-loaded structural parts with high forming requirements |

Not sure about alloy selection? Contact us for expert selection advice and a free sample evaluation.

Industry solutions

Aerospace

Large frame components often involve complex loads and require multiple machining steps. Conventional sheet metal cutting not only results in significant material waste but also incurs significant processing costs. Using AMS 4928 Grade 5 titanium flat bar as a near-net-size blank, we can directly saw to an accuracy of ±0.125″.

Typical components: fuselage reinforcement beams, seat rails, satellite load-bearing brackets, and engine support rings.

Medical devices

Implantable parts require low impurities and a high surface finish, but traditional stainless steel plates struggle to achieve both biocompatibility and lightweight performance. Using Grade 23 ELI titanium flat bar, precision milled and polished to Ra ≤ 0.8 µm, we can form high-precision bone plates and surgical fixtures in a single step, reducing the risk of subsequent grinding and sterilization.

Typical components: spinal fixation plate, titanium alloy clamp body, bone connector base.

Offshore Engineering / Desalination

Stainless steel heat exchanger plates and pump casings are prone to pitting corrosion in chloride-containing environments, leading to high downtime and costly replacement. Using Grade 2 pure titanium flat bar to manufacture tube sheets and baffles can provide over 20 years of continuous service in 3.5% NaCl seawater without pitting corrosion, significantly reducing lifecycle costs.

Typical components: multi-stage flash heat exchanger tube sheets, seawater pump casing support frames, condenser baffles.

For projects requiring multiple structural profiles, we also supply titanium round bars, square bars, and hexagonal bars in matching grades and specifications. Integrating different titanium bar shapes within the same material system helps optimize machining processes, ensure dimensional compatibility, and simplify procurement management. Whether your application involves flat bar sections for structural frames or round and hex bars for shaft and fastening components, we provide coordinated supply support for complete project solutions.

Processing services and quality assurance

Processing and secondary services

- It supports saw cutting and water jet cutting with a tolerance of ±0.25 mm, suitable for blanking of various specifications and complex shapes.

- It can perform secondary processing such as CNC milling, drilling, chamfering, etc. to meet the needs of positioning structural parts and fasteners.

- Groove processing and pre-welding positioning treatment can be provided upon request to facilitate customers' subsequent assembly and welding operations.

- We accept STEP and DWG drawings provided by customers, carry out precision processing according to the drawings and support sample confirmation.

Surface treatment services

- It can be pickled and passivated to effectively remove oxide scale and improve corrosion resistance, making it suitable for marine and chemical environments.

- We provide sandblasting roughening services, which are suitable for structural parts that require subsequent welding or surface coating to enhance adhesion.

- Supports mirror polishing of Ra ≤ 0.8 µm, meeting the cleanliness and surface finish requirements of the medical and life science fields.

- Optional anodizing treatment is available, providing color layers such as industrial gray, blue, and gold, suitable for appearance or functional customization (it is recommended to confirm process compatibility first).

Quality inspection and material traceability

- Provide PMI spectrum analysis to ensure the stability and consistency of the supplied titanium alloy composition (such as Gr2, Gr5, Gr23).

- Supports ultrasonic (UT) testing to ensure that there are no cracks or inclusions inside the material, meeting the quality requirements of the aviation field.

- Can conduct hardness and dimension re-inspection, supporting testing standards such as Rockwell or Brinell.

- Each batch of materials can be accompanied by an EN 10204 3.1 / 3.2 material report, and supports third-party witness inspections such as SGS and TÜV.

Packaging and Shipping

- All titanium flat bars are sealed with vacuum bags, anti-rust VCI film, foam spacers, and reinforced export-grade plywood boxes to ensure no damage during transportation.

- We support FedEx/DHL express delivery (for urgent orders ≤50 kg). For large orders, we can arrange air freight, sea freight or full container shipment.

- Regular sizes in stock can be shipped within 48 hours at the earliest, and will include a packing list, material certificate and all required customs documents.

FAQ

Can titanium flat bar be welded directly to stainless steel or aluminum alloy?

Direct fusion welding of titanium with stainless steel or aluminum can form brittle intermetallic compounds, leading to joint failure. In engineering, titanium-stainless steel (or titanium-aluminum) explosive composite transition joints are commonly used, or mechanical connections using titanium sleeves or bolts under inert protection are performed. If dissimilar material welding is necessary, assess the risk of weld embrittlement and control heat input.

What surface finish grades do you offer?

The standard industrial finish is pickled and passivated (Ra ≈ 3.2 µm). For higher finishes, sandblasting (Ra ≈ 1.6 µm), mechanical polishing (Ra ≤ 0.8 µm), mirror polishing (Ra ≤ 0.2 µm), or anodized finishes are available. Please specify your target Ra value and intended use when inquiring, and we will recommend the most economical processing route.

What is the minimum bend radius of Grade 5 titanium flat bar?

In the annealed state, the recommended minimum internal bend radius for cold bending is 3 x t of the material thickness. If a smaller radius is required, local heating or aging followed by chamfering can be used. Please provide the thickness and bend angle, and we can use FEA to assess formability.

How should titanium flat bar inventory be stored to prevent contamination and oxidation?

It is recommended to store in a dry, chloride-free warehouse at a temperature of 5-30°C and a relative humidity of <60%. Flat bars should be kept in vacuum bags or sealed plastic wrap to avoid direct contact with carbon steel tools to prevent scraping and cross-contamination. For long-term storage, it is recommended to re-inspect the surface condition every 12 months.

Is there a minimum order quantity for custom sizes?

The minimum order quantity (MOQ) for standard Grade 2/5 flat bar cut to length is 10 kg or a single piece (depending on the size). If the size exceeds the existing parent material specifications, new blanks will be required, and the minimum order quantity is typically 50 kg or more. Our sales staff can quickly calculate the optimal procurement plan based on the drawing.

Are there any recommended tools and parameters for titanium flat bar machining?

We recommend using Ti-Al-N coated carbide cutting tools with a 90° entering angle and a 10-15° rake angle. Dry cutting or using a low-chloride water-soluble cutting fluid is acceptable. Line speeds are 40-60 m/min (Grade 2) or 30-50 m/min (Grade 5/23), with a feed rate of 0.05-0.15 mm/rev. To avoid workpiece deformation, use multiple shallow cuts and maintain adequate cooling. A detailed process sheet is available free of charge after placing your order.

Titanium flat bar in stock

Below is a list of the specifications of titanium flat bar that Chalco Titanium always has in stock. We offer Grade 2, Grade 5, and Grade 23 alloys in a variety of thicknesses, widths, and lengths, making them suitable for cutting and processing in diverse fields such as aviation, medical, and industrial.

| Alloy Grade | Product Name | Thickness (in) | Width (in) | Length (in) |

|---|---|---|---|---|

| Grade 2 | Titanium Flat Bar 0.020×0.50×36" | 0.02 | 0.5 | 36 |

| Grade 2 | Titanium Flat Bar 0.032×0.75×48" | 0.032 | 0.75 | 48 |

| Grade 2 | Titanium Flat Bar 0.035×1.00×72" | 0.035 | 1 | 72 |

| Grade 2 | Titanium Flat Bar 0.063×1.50×96" | 0.063 | 1.5 | 96 |

| Grade 2 | Titanium Flat Bar 0.078×2.00×120" | 0.078 | 2 | 120 |

| Grade 2 | Titanium Flat Bar 0.125×2.50×36" | 0.125 | 2.5 | 36 |

| Grade 2 | Titanium Flat Bar 0.250×3.00×48" | 0.25 | 3 | 48 |

| Grade 2 | Titanium Flat Bar 0.020×4.00×72" | 0.02 | 4 | 72 |

| Grade 2 | Titanium Flat Bar 0.032×6.00×96" | 0.032 | 6 | 96 |

| Grade 2 | Titanium Flat Bar 0.035×1.00×120" | 0.035 | 1 | 120 |

| Grade 5 | Titanium Flat Bar 0.020×0.50×36" | 0.02 | 0.5 | 36 |

| Grade 5 | Titanium Flat Bar 0.032×0.75×48" | 0.032 | 0.75 | 48 |

| Grade 5 | Titanium Flat Bar 0.035×1.00×72" | 0.035 | 1 | 72 |

| Grade 5 | Titanium Flat Bar 0.063×1.50×96" | 0.063 | 1.5 | 96 |

| Grade 5 | Titanium Flat Bar 0.078×2.00×120" | 0.078 | 2 | 120 |

| Grade 5 | Titanium Flat Bar 0.125×2.50×36" | 0.125 | 2.5 | 36 |

| Grade 5 | Titanium Flat Bar 0.250×3.00×48" | 0.25 | 3 | 48 |

| Grade 5 | Titanium Flat Bar 0.020×4.00×72" | 0.02 | 4 | 72 |

| Grade 5 | Titanium Flat Bar 0.032×6.00×96" | 0.032 | 6 | 96 |

| Grade 5 | Titanium Flat Bar 0.035×1.00×120" | 0.035 | 1 | 120 |

| Grade 5 | Titanium Flat Bar 0.100×2.00×60" | 0.1 | 2 | 60 |

| Grade 5 | Titanium Flat Bar 0.150×2.50×84" | 0.15 | 2.5 | 84 |

| Grade 5 | Titanium Flat Bar 0.200×3.00×100" | 0.2 | 3 | 100 |

| Grade 5 | Titanium Flat Bar 0.300×3.50×72" | 0.3 | 3.5 | 72 |

| Grade 5 | Titanium Flat Bar 0.375×4.00×120" | 0.375 | 4 | 120 |

| Grade 23 | Titanium Flat Bar 0.020×0.50×36" | 0.02 | 0.5 | 36 |

| Grade 23 | Titanium Flat Bar 0.032×0.75×48" | 0.032 | 0.75 | 48 |

| Grade 23 | Titanium Flat Bar 0.035×1.00×72" | 0.035 | 1 | 72 |

| Grade 23 | Titanium Flat Bar 0.063×1.50×96" | 0.063 | 1.5 | 96 |

| Grade 23 | Titanium Flat Bar 0.078×2.00×120" | 0.078 | 2 | 120 |

| Grade 23 | Titanium Flat Bar 0.125×2.50×36" | 0.125 | 2.5 | 36 |

| Grade 23 | Titanium Flat Bar 0.250×3.00×48" | 0.25 | 3 | 48 |

| Grade 23 | Titanium Flat Bar 0.020×4.00×72" | 0.02 | 4 | 72 |

| Grade 23 | Titanium Flat Bar 0.032×6.00×96" | 0.032 | 6 | 96 |

| Grade 23 | Titanium Flat Bar 0.035×1.00×120" | 0.035 | 1 | 120 |

| Grade 23 | Titanium Flat Bar 0.150×2.00×60" | 0.15 | 2 | 60 |

| Grade 23 | Titanium Flat Bar 0.200×2.50×84" | 0.2 | 2.5 | 84 |

| Grade 23 | Titanium Flat Bar 0.300×3.00×100" | 0.3 | 3 | 100 |