Titanium Pipe Fittings Supplier

Titanium fittings provide outstanding corrosion resistance, a high strength-to-weight ratio, and reliable sealing—making them ideal for demanding piping systems in chemical, marine, and automotive industries.

Available in grades GR1, GR2, GR7, and GR12, our products meet ASTM and ASME standards. We support one-stop sourcing with reliable lead times, consistent quality, and competitive pricing.

Specifications of titanium pipe fittings

- ASME B16.9, ASME B16.11, ASME B16.5, ASME B16.47

- ASTM B363

- ASTM B338

- ASTM B381

- BS 3799

- DIN 28011

Our titanium fittings meet EN 10204 3.1/3.2, NACE MR0175 / ISO 15156, and are manufactured under ISO 9001 and AS9100 certified quality systems.

Titanium Alloy Selection for Pipe Fittings

-

Gr 2

General-purpose corrosion resistance with great cost performance. Chemical pipelines, seawater desalination systems.

-

Gr 7

Contains 0.15% palladium for superior resistance to chloride-induced pitting. Chlor-alkali systems, electrolysis units, offshore platforms.

-

Gr 12

High strength and excellent weldability. High-pressure oil & gas systems, steam recovery loops.

Popular titanium pipe fittings

We offer a complete selection of titanium fittings, including elbows, tees, reducers, threaded components, and more. Click on any product name below to view available sizes and specifications.

| Product | Standard Sizes | Schedule | Available Grades |

|---|---|---|---|

| Titanium elbow | 1/2" – 48" | 10S / 40S | Gr 2, Gr 7, Gr 12 |

| Titanium reducer | 3/4 " x 1/2 " - 16" x 14" | 10S / 40S | Gr 2, Gr 7, Gr 12 |

| Titanium tee / cross | 1/2 " x 1/2 " - 10" x 4" | 10S / 40S | Gr 2, Gr 7 |

| Titanium stub end | 1/2 " x 24" | 10S / 40S | Gr 2, Gr 7 |

| Titanium coupling | 1/4 " x 2" | 10S / 40S | Gr 2, Gr 7 |

| Titanium cap | 1/2 " x 48" | 10S / 40S | Gr 2, Gr 7 |

| Titanium pipe plugs | 1/4 " x 4" | 10S / 40S | Gr 2, Gr 7 |

We supply a full range of titanium pipe fittings with three main connection types:

- Socket-weld fittings: Ideal for small-diameter, high-pressure systems; easy to weld.

- Butt-weld fittings: Suitable for main pipelines with low flow resistance and high strength.

- Threaded fittings: Perfect for removable joints or instrument connections; easy to install and maintain.

Each fitting is permanently marked using electrochemical etching, in compliance with ASME B16.9 standards.

Theoretical product weight is calculated based on a titanium density of 0.163 lbs/in³.

Titanium elbow

We offer titanium elbows in Grade 1, Grade 2, and Grade 7, with customizable angles and multiple connection options including butt weld, threaded, and NPT types.

Contact us now

- Standard angles: 45°, 90°, and 180°

- Bend radius options: 1.0D, 1.2D, 1.5D, 3D

- End finish: Beveled ends, optional argon gas pre-sealing

- Size range: 0.5" to 48"

- Dimensional tolerances meet ASME B16.9 standards

- Common schedules: 10S and 40S

For custom dimensions or special requirements, please contact us for a quote. Quick Quote

Titanium 45° Elbows

Titanium 90° Elbows

Titanium 180° Elbows

Titanium reducer

Titanium reducers are available in two types: concentric and eccentric. Common materials include Grade 2 and Grade 12.

Contact us now

- Size range: from 3/4" (19.1 mm) × 1/2" (12.7 mm) up to 16" (406.4 mm) × 14" (355.6 mm)

- Wall thickness: S10 and S40, compliant with ASTM B363 and ASME B16.9 standards

Sizes 4" and below are made from seamless titanium tube; larger sizes are fabricated from titanium plate with 100% X-ray inspection on all welds to ensure structural integrity. Quick Quote

Titanium Eccentric Reducer

Titanium Concentric Reducer

Titanium Reducer Cone

Titanium tee / cross

We offer a complete range of titanium tees and crosses, including straight tees, reducing tees, straight crosses, and reducing crosses. Common materials include Grade 2 and Grade 7.

- Size range: 1/2" (12.7 mm) to 24" (609.6 mm), compliant with ASME/ANSI B16.9

- Wall thickness: S10 and S40, per ASME B36.19M

- End types: Beveled or plain

- Surface finish: Polished to Ra ≤ 0.8 µm (ISO 15156) available

For custom designs such as socket-weld or threaded tees, please feel free to request a quote. Quick Quote

Titanium stub end

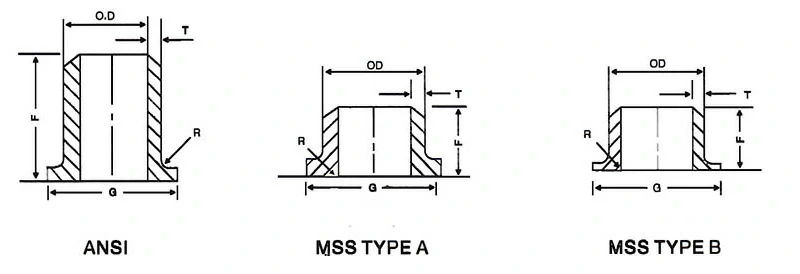

Our stock sizes for titanium stub ends range from 0.5" (12.7 mm) to 8" (203.2 mm), covering both MSS Type A short pattern and ASA Type B long pattern designs.

Contact us now

We offer various sizes of titanium alloy stub ends with dimensional tolerances in accordance with ASME B16.9 and wall thickness options following ASME B36.19M standards for S10 and S40.

The sealing face is machined with a serrated spiral finish as per ASME B16.5, ensuring a tight and reliable seal with flanges.

Compatible with carbon steel lap joint flanges, this design reduces titanium usage by up to 30% while maintaining a corrosion-resistant contact surface—effectively lowering overall costs.

Titanium coupling

We stock a variety of titanium leak-proof couplings in multiple alloy grades, with commonly available diameters ranging from 1/4" to 2".

Contact us now

Threaded, socket-weld, and reducing types are available in both full and half coupling designs. Custom sizes and specifications are also supported—contact us for a tailored quote for your project. Quick Quote

Socket-weld titanium coupling

Threaded titanium coupling

Half titanium coupling

Titanium cap

Chalco Titanium offers a wide range of titanium end caps in various shapes, including elliptical, dished, hemispherical, torispherical, conical, and standard pipe caps—designed to meet different sealing and structural requirements.

Titanium pipe plugs

Titanium pipe plugs are available in stock with reliable, high-precision threaded sealing. Customization and fast delivery are supported to meet urgent project needs.

Contact us now

Solid hex titanium plug

Threaded solid hex titanium plug

Corrosion-resistant socket-weld titanium plug

Why choose titanium fittings over other metal options?

Exceptional resistance to pitting corrosion

At 25 °C in 3.5% NaCl, commercially pure titanium has a critical pitting potential over +1.7 V SCE, compared to only +0.3 V SCE for 316L stainless steel—which may perforate within 1–2 years.

Titanium remains virtually immune to pitting under the same conditions, requiring no coatings or cathodic protection.

Outstanding strength-to-weight ratio

Grade 5 titanium offers yield strength up to 828 MPa at just 60% of steel’s weight. In high-pressure piping or automotive exhaust systems, wall thickness can be reduced by 15–30%, significantly lowering weight and structural loads.

High purity with zero heavy metal leaching

Titanium contains no leachable ions such as Ni or Cu, making it ideal for semiconductor ultrapure water and pharmaceutical WFI systems that demand metal ion levels below 1 ppb.

This minimizes contamination risk and reduces validation and compliance burdens.

Lifetime cost (LCC) advantage

Though the initial price is 4–6 times higher than 316L, titanium can deliver over 10 years of maintenance-free service in highly corrosive environments.

For example, in an oil & gas plant with one shutdown per year costing $200,000, switching to titanium can save over $800,000 in five years—more than offsetting the material cost.

Titanium vs. stainless steel pipe fittings: cost comparison

| Cost Item | Steel / Stainless Steel | Titanium Alloy |

|---|---|---|

| Initial material cost | Lower | Higher |

| Corrosion rate | Prone to pitting and crevice attack | Near "zero corrosion” |

| Maintenance frequency | Replacement every 12–24 months | No replacement for ≥10 years |

| Downtime losses | Hundreds of thousands per shutdown | Virtually none |

| Total cost over 10 years | Looks cheap but costs more long term | Pays back over time, low upkeep |

Steel and stainless steel may seem cost-effective at first, but frequent repairs and corrosion drive up total expenses. Titanium’s higher upfront cost is quickly recovered through long-term durability and maintenance savings.

Why choose us

As a direct factory supplier in China, we offer a full range of titanium pipe fittings in Grade 2, Grade 5, Grade 7, and Grade 12. All products can be customized to ASME, ASTM, or ISO standards. Our prices are significantly lower than those of European, American, and Russian brands—giving you a true competitive edge.

- Same performance, with much lower initial purchase cost

- Shorter lead times, low MOQs, and rapid delivery

- Complete quality inspection and certification system

- Seamless support for project schedules, third-party inspection, and export clearance

Contact us today for a formal quotation. Quick Quote

Titanium pipe fittings FAQ

Can titanium fittings be welded directly to stainless steel?

No. A titanium-to-stainless steel explosion-bonded transition joint is required. Direct dissimilar welding forms brittle intermetallic compounds.

Use pure argon shielding during welding with O₂ < 50 ppm.

What’s the maximum long-term operating temperature for titanium fittings?

Commercially pure titanium can withstand up to 300 °C continuously, while Grade 5 can handle up to 400 °C.

In exhaust systems, short-term exposure above 700 °C is possible with proper air cooling.

What surface treatments are available?

Standard finish is acid pickled and passivated, Ra ≤ 3.2 µm.

Optional finishes include polishing to Ra ≤ 0.8 µm, sandblasting, or anodizing for decorative or cleanliness needs.

Do you support custom lengths or special shapes?

Yes. We can manufacture oversized or non-standard titanium fittings based on your drawings or technical specs.

How are the fittings packaged and shipped?

All titanium fittings are vacuum-sealed and wrapped in bubble film, then packed in fumigation-free wooden crates.

For sea freight, desiccants are included. Air shipments follow IATA Dangerous Goods Packing Standard 903 to prevent salt spray and impact damage.